Method for controlling SPE water electrolysis efficiency

A technology for electrolysis of water and efficiency, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of high cost, cumbersome process and complex technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

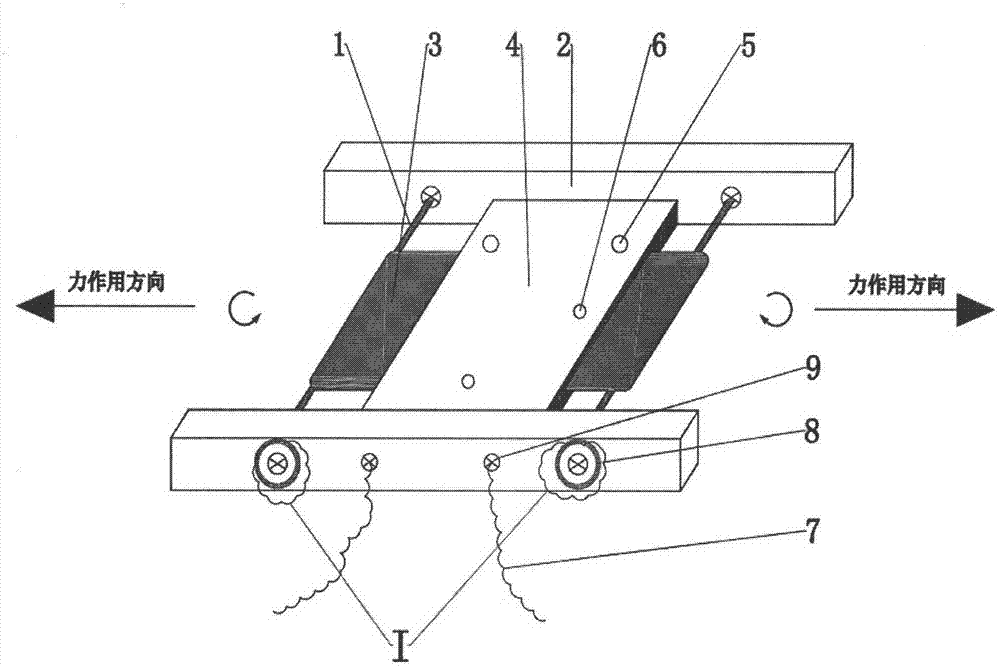

[0028] (1) The titanium mesh is selected as the diffusion layer, and the catalyst-free membrane is selected for the membrane electrode, and the electrolysis device and the stretching device are assembled in turn according to the requirements, and the two are combined for use, (such as attached figure 1 ), in the figure: 1, the rotating shaft, 2, the supporting frame of the stretching device, 3, the membrane electrode, 4, the SPE water electrolysis device (remove the membrane electrode part), 5, the water injection hole, 6, the escape hole, 7, the connecting wire, 8. Measuring ruler, 9. Round hole.

[0029] (2) Fill the above assembled device with water to test the electrolytic water in the natural state of the membrane, and use the potentiodynamic scanning method to test the scanning potential. Current density-potential diagram.

[0030] (3) Disassemble the electrolysis device, separate the membrane electrode from the titanium mesh that is in contact with both sides, and then...

Embodiment 2

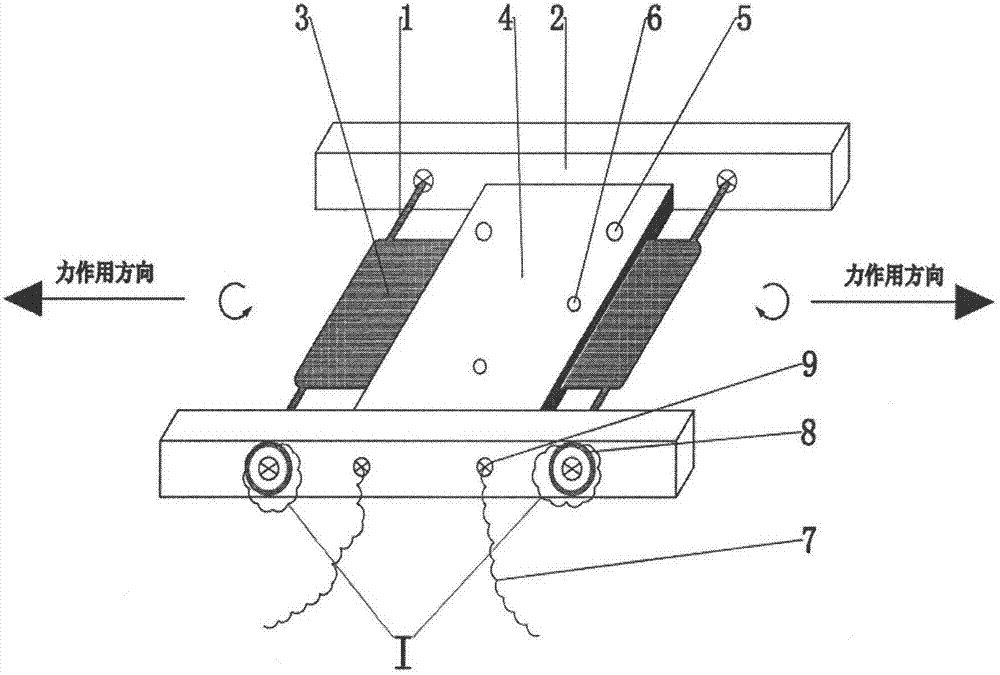

[0034] (1) Titanium mesh is selected as the diffusion layer, and the membrane electrode is selectively applied with a Pt catalytic dosage of 2mg / cm 2 coating, assemble the electrolyzed water device and the stretching device in turn according to the requirements, and combine the two for use, (as attached figure 2 ), in the figure: 1, the rotating shaft, 2, the supporting frame of the stretching device, 3, the membrane electrode, 4, the SPE water electrolysis device (remove the membrane electrode part), 5, the water injection hole, 6, the escape hole, 7, the connecting wire, 8. Measuring ruler, 9. Round hole.

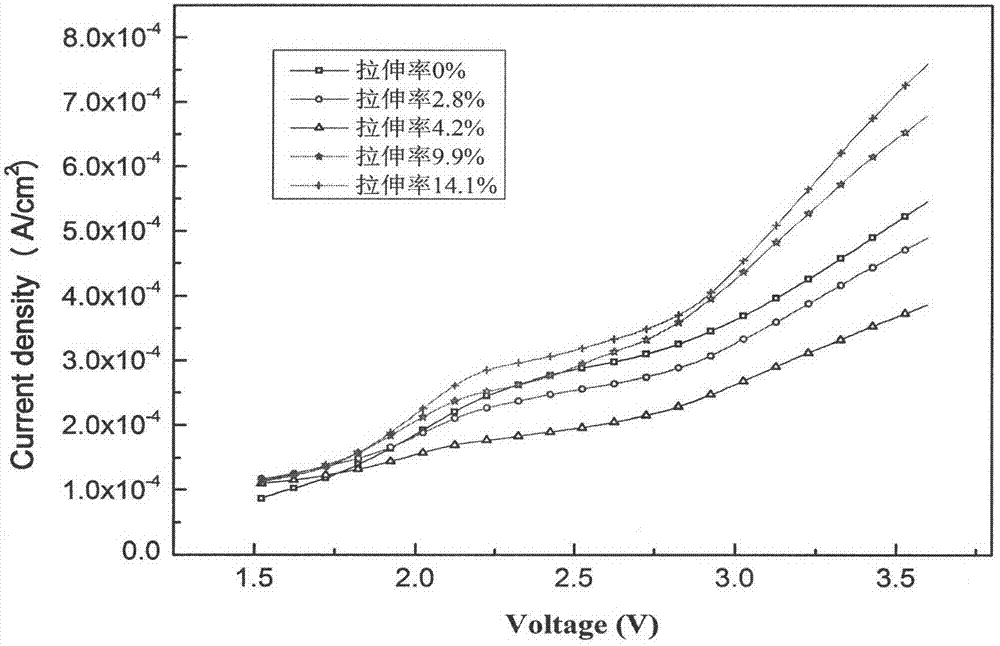

[0035] (2) Fill the above assembled device with water to test the electrolyzed water in the natural state of the coating, and use the potentiodynamic scanning method to test. The scanning potential is selected from 1.5v to 3.6v to obtain the natural state, that is, when the elongation rate is zero. Current density-potential diagram.

[0036] (3) Disassemble the electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com