Angle steel galvanized numerical control threading and hanging device and threading and hanging process

An angle steel and hang-on technology, which is applied in hot-dip galvanizing process, metal material coating process, coating, etc., can solve the problems of unfavorable angle steel galvanizing mass production operations, etc., so as to improve the hanging efficiency and occupy a small space , Reduce the effect of wearing and hanging labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

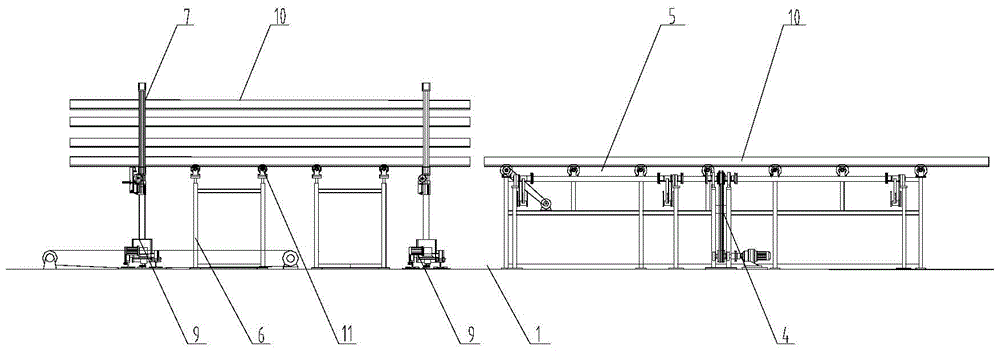

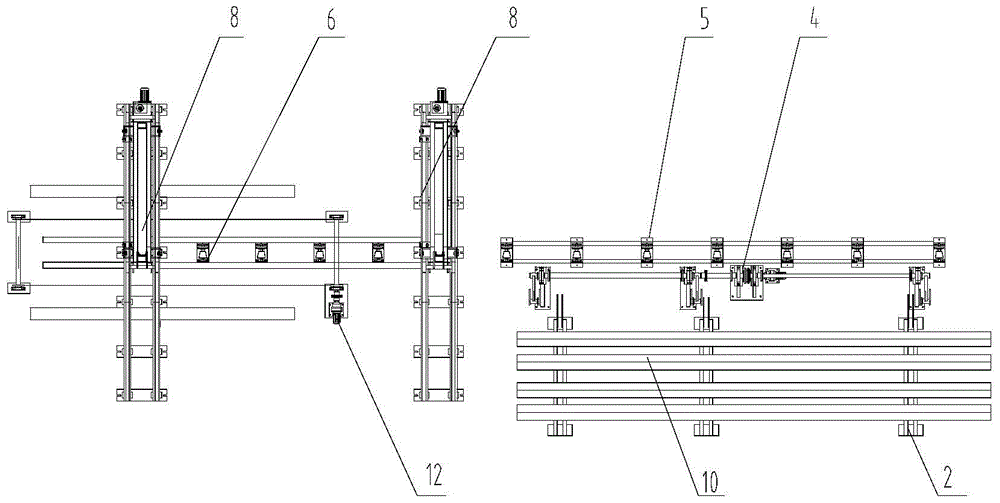

[0028] The invention discloses a galvanized angle steel numerical control threading and hanging device, which realizes the fast and accurate threading and hanging operation of galvanized angle steel, see Figure 1-Figure 3 , the device is mainly composed of workbench 1, feeding rack 2, angle steel positioning seat 3, material turning device 4, feeding roller table 5, material passing roller table 6, feeding grate 7, moving guide rail 8 and grate clamping and lifting Run the trolley with 9 components.

[0029] Wherein, the moving guide rail 8 is installed vertically above the workbench 1, and includes 2 moving guide rails 8 arranged in parallel. The upper part of each moving guide rail 8 is equipped with a grate clamping lifting operation trolley 9, and the grate clamping lifting operation trolley 9 Controlled by a numerical control device, the trolley 9 is controlled by the lifting motor to clamp and lift the grate to realize quantitative movement up, down, left, and right. T...

Embodiment 2

[0044] The structure and composition of the threading and hanging device of embodiment 2 are basically the same as those of the threading and hanging device of embodiment 1, and the difference is that the rollers on the feeding roller table and the passing roller table adopt polygonal rollers or Angled rollers prevent the angle steel from running off during the hanging process, and the rollers are arranged at equal intervals on the two roller tables.

[0045] Those skilled in the art can understand that the accompanying drawing is only a schematic diagram of a preferred embodiment, and the workflow in the accompanying drawing is not necessarily necessary for implementing the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com