Cold galvanizing coating and preparation method thereof

A technology of cold galvanizing and coating, which is applied in the direction of anti-corrosion coatings and coatings, which can solve problems such as deficiencies, coating blister protection, etc., and achieve the effects of improving shielding performance, improving paint film durability, and ensuring electrochemical protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

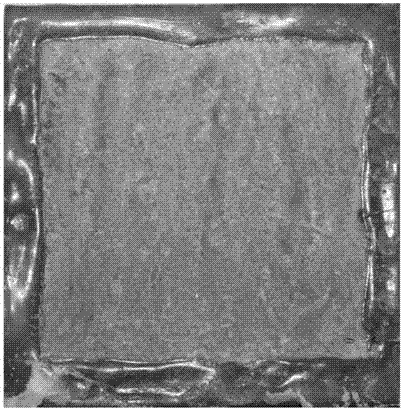

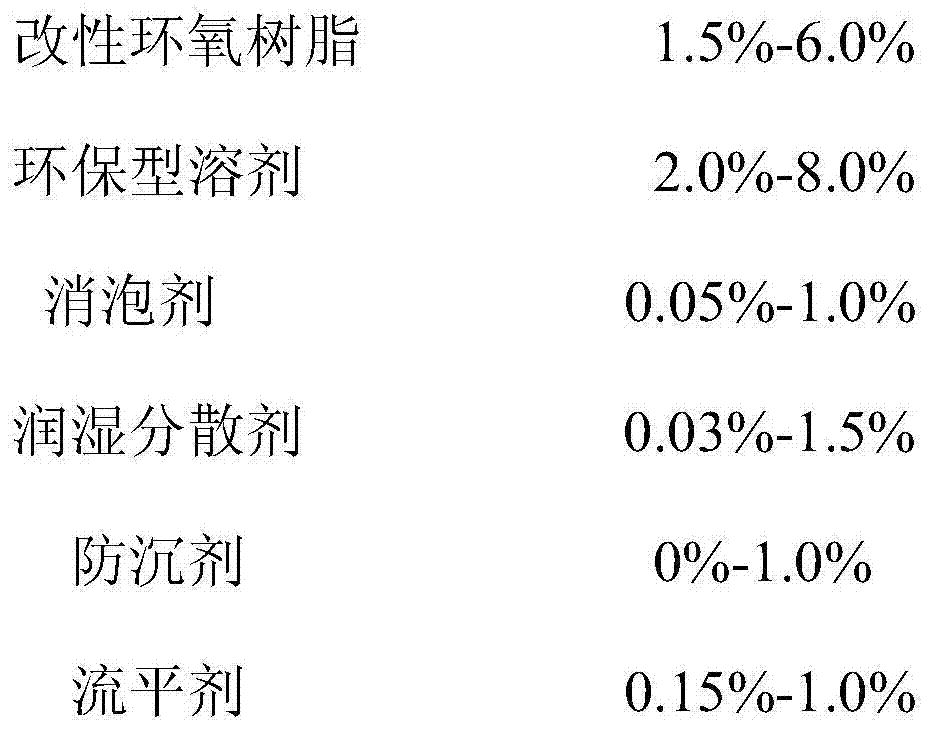

Embodiment 1

[0033]A kind of preparation method of cold-dip galvanized paint, concrete steps are as follows: add 5.5% PMA solvent and 4.0% modified epoxy resin EPOKEY-868 (Japan Mitsui) in the paint tank with cooling device, stir 10min at 500rpm ;Continue to add 0.15% wetting and dispersing agent BYK-P104, 0.3% defoamer HX-2085 (Huaxia Pentium), 1.0% anti-settling agent A630-20X (Disparon), and stir at 1000rpm for 20min; Add 88.5% zinc powder and 0.3% silane coupling agent γ-glycidyl etheroxypropyl trimethoxysilane (KH-560), increase the speed to 2500rpm, stir at high speed for 30min, after adding zinc powder and surface modification During the stirring of the agent, use circulating water to keep the paint mixing tank cool. After the stirring is completed, reduce the speed to 1500rpm, add 0.15% leveling agent AFCONA-3777, continue stirring for 15 minutes, reduce the speed to 600rpm, stir for 10 minutes, and pack it out. . The corrosion resistance of the obtained film reaches 2400h.

[00...

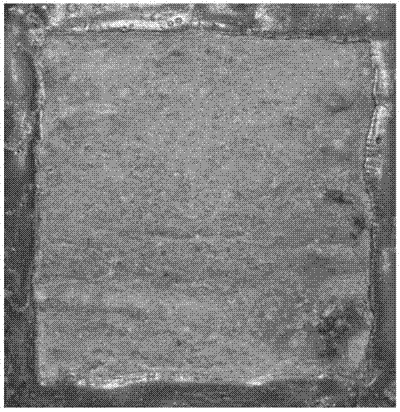

Embodiment 2

[0036] A kind of preparation method of cold-dip galvanized paint, concrete steps are as follows: add 3% environmental protection solvent sec-butyl acetate and 3% modified epoxy resin EPOKEY-868 (Japan Mitsui) in the paint tank of band cooling device, in Stir at 500rpm for 10min; continue to add 0.05% of wetting and dispersing agent BYK-P104, 0.1% of defoamer HX-2085 (Huaxia Pentium), 0.5% of anti-settling agent A630-20X (Disparon), at 1000rpm Stir for 20 minutes; add 92.15% zinc powder and 1.0% titanate coupling agent tetraisopropyl bis(dilauryl phosphite) titanate, increase the speed to 2500rpm, stir at high speed for 30 minutes, and add zinc powder and surface During the stirring of the modifier, use circulating water to keep the paint mixing tank cool. After the stirring is completed, reduce the speed to 1500rpm, add 0.2% leveling agent, continue stirring for 15 minutes, reduce the speed to 600rpm, stir for 10 minutes, and then pack it out. The corrosion resistance of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com