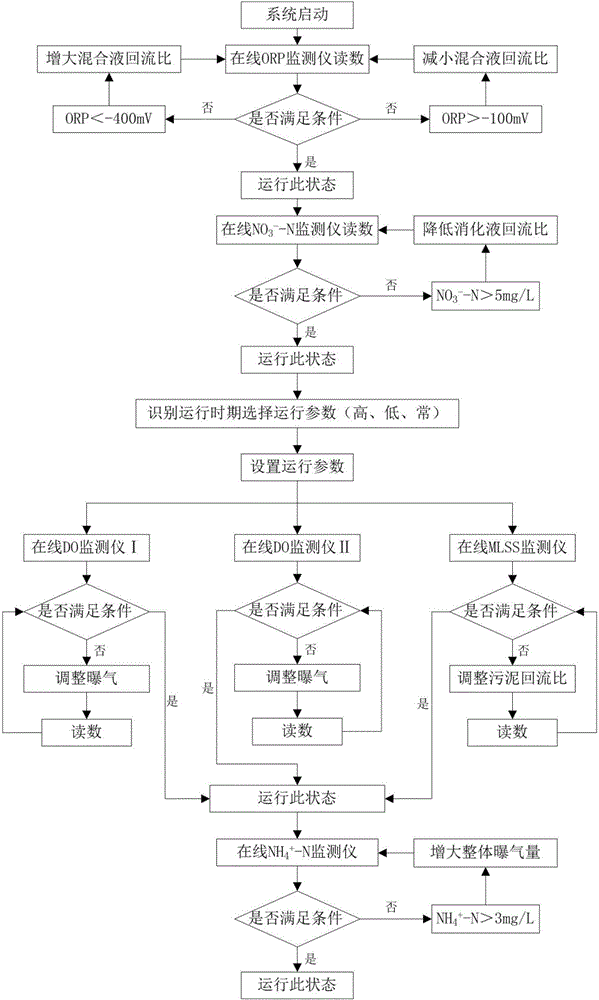

An AAO oxidation ditch real-time control system and its sewage treatment method

A real-time control and oxidation ditch technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, biological treatment adjustment methods, etc. To achieve the effect of strengthening the effect, optimizing the quantity and operation mode, and reducing the operation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Example 1: High temperature period (>25°C):

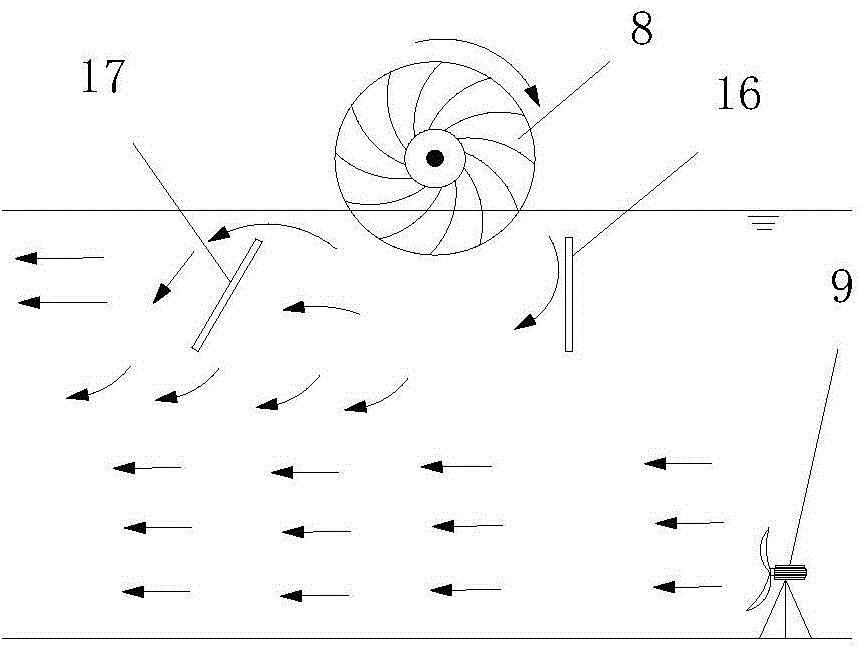

[0055] The initial state of each aeration turntable is: A# aeration turntable speed 80r / min, B# aeration turntable speed 100r / min, C# aeration turntable speed 80r / min. The three aeration turntables are all continuously variable speed control; the initial value of the sludge reflux ratio R is 80%; the mixed liquid reflux ratio r from the anoxic tank to the anaerobic tank 1 70%; the reflux ratio of the nitrification liquid from the oxidation ditch to the anoxic tank r 2 150%; the water inlet state is a single point water inlet of the anaerobic tank.

[0056] Based on this, the following conditions are regulated:

[0057] a. The reading of DO monitor I<1.0mg / L

[0058] Increase the rotation speed of the B# aeration turntable by 10r / min, continue for 1h, and then monitor again. If it is still below the normal range, increase it by 50r / min, and repeat the process until the maximum rotation speed does not exceed 130r / min.

[0059] b. The r...

Embodiment 2

[0076] Example 2: Low temperature period (<15°C):

[0077] The initial state of operation of each aeration turntable is: A# aeration turntable speed 100r / min, B# aeration turntable speed 100r / min, C# aeration turntable speed 100r / min. All three aeration turntables are infinitely variable speed control. The initial value of sludge reflux ratio is 80%; the nitrification liquid reflux ratio is 250%; multi-point water inflow is adopted, and the ratio of anaerobic tank and anoxic tank is 7:3; the mixed liquid from anoxic tank to anaerobic tank is returned The ratio is 70%.

[0078] Based on this, the following conditions are regulated:

[0079] a. The reading of DO monitor I<1.0mg / L

[0080] Increase the rotation speed of the B# aeration turntable by 10r / min, continue for 1h, and then monitor again. If it is still below the normal range, increase it by 10r / min, and repeat the process until the maximum rotation speed does not exceed 130r / min.

[0081] b. The reading of DO monitor I>2.0mg / L...

Embodiment 3

[0098] Example 3: Normal temperature period (15-25°C):

[0099] The initial state of operation of each aeration turntable is: A# aeration turntable speed 100r / min, B# aeration turntable speed 100r / min, C# aeration turntable speed 100r / min. All three aeration turntables are infinitely variable speed control. The initial value of the sludge reflux ratio is 80%; the nitrification liquid reflux ratio is 200%; the water inlet state is a single-point water inlet; the mixed liquid reflux ratio from the anoxic zone to the anaerobic zone is 70%.

[0100] Based on this, the following conditions are regulated:

[0101] a. The reading of DO monitor I<1.0mg / L

[0102] Increase the rotation speed of the B# aeration turntable by 10r / min, continue for 1h, and then monitor again. If it is still below the normal range, increase it by 10r / min, and repeat the process until the maximum rotation speed does not exceed 130r / min.

[0103] b. The reading of DO monitor I>2.0mg / L

[0104] Decrease the rotation sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com