Method for automatic sticking of electronic tag

An electronic label, automatic sticking technology, applied in labels, labeling machines, packaging, etc., to reduce the error rate, easy to use, and scientifically designed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

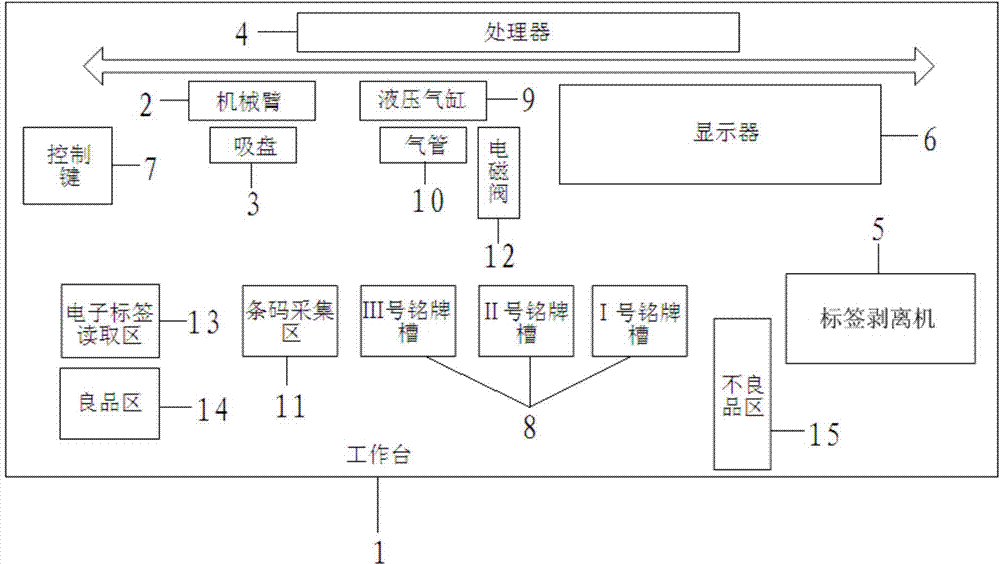

[0017] The electronic label automatic sticking method involved in this embodiment specifically includes the following process steps:

[0018] (1) Place the electronic label to be attached on the label peeling machine 5, and put the nameplates of the corresponding number segments into the three nameplate slots 8 in order from small to large; open the general control of the electronic label automatic sticking device Power supply, the mechanical arm 2 drives the suction cup 3 to automatically locate the starting point according to the preset program in the processor 4, and moves to the position just above the electronic label peeled off on the label peeling machine 5;

[0019] (2) The display (LCD) 6 displays "press the OK key to run" according to the preset instruction in the processor 4, and press the control key (OK key) 7 at this time, if there is no peeled electronic label or nameplate directly under the suction cup 3 If there is no nameplate in the slot 8, the display 6 wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com