Automatic welding device for auger stem fin

An automatic welding and auger rod technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of low welding operation efficiency, difficult to guarantee welding quality, high labor intensity, etc., and achieve high welding operation efficiency and adjustment. Simple, convenient and highly automated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

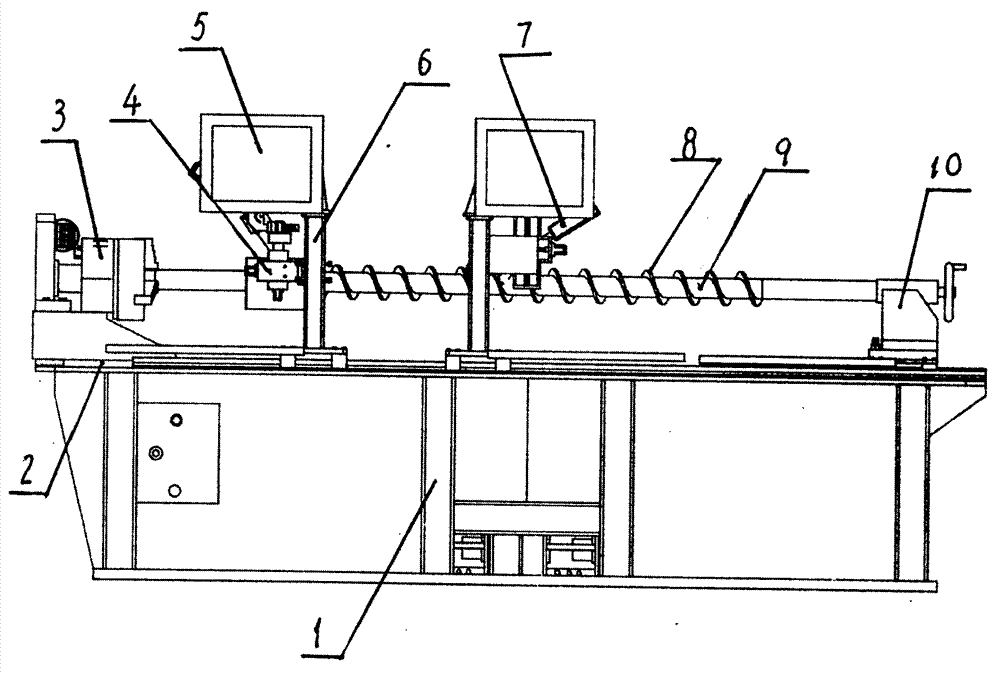

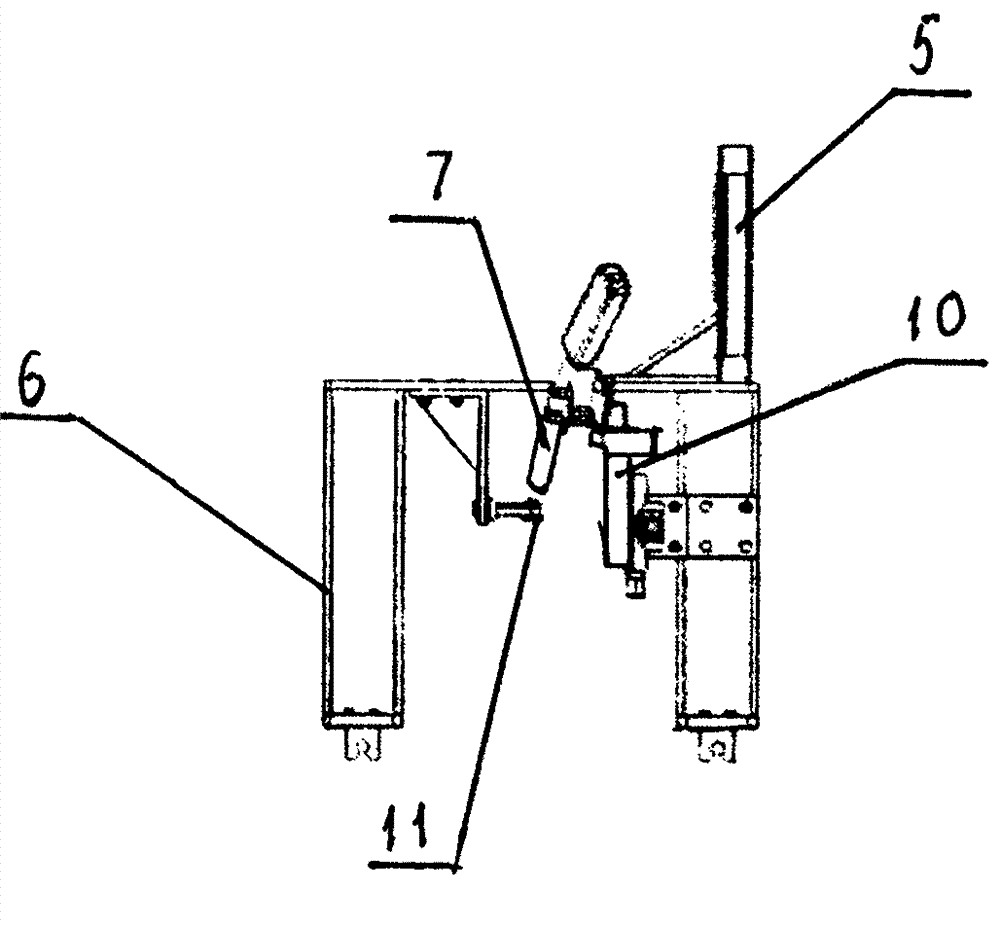

[0010] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. An automatic welding device for auger pipe fins includes a bed 1, on which a guide rail 2 is fixed, a headstock 3 is fixed on the left side of the bed 1, and a tailstock 0 is arranged on the On the right side of the bed 1, two moving frames 6 are fitted on the bed 1 in cooperation with the guide rail 2 and can move left and right laterally, and the fine-tuning assembly 4, arc-proof plate 5 and rollers are installed on the moving frame 6 11. The welding torch 7 is installed on the trimming assembly 4.

[0011] When the operation is in use, the blade shaft 9 that has been spot-welded and positioned on the blade shaft 9 with the spiral fin 8 is clamped and installed on the headstock 3 and the tailstock 10, and then the two rollers 11 on the two mobile frames 6 are respectively Contact and cooperate with the opposite sides of the helical fins 8, and then ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com