Die-casting die for automobile engine upper shell installation and secondary core pulling

An automobile engine and die-casting mold technology, applied in the field of metal die-casting molds, can solve the problems of low work efficiency, unsecured workers' safety, and high labor intensity of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

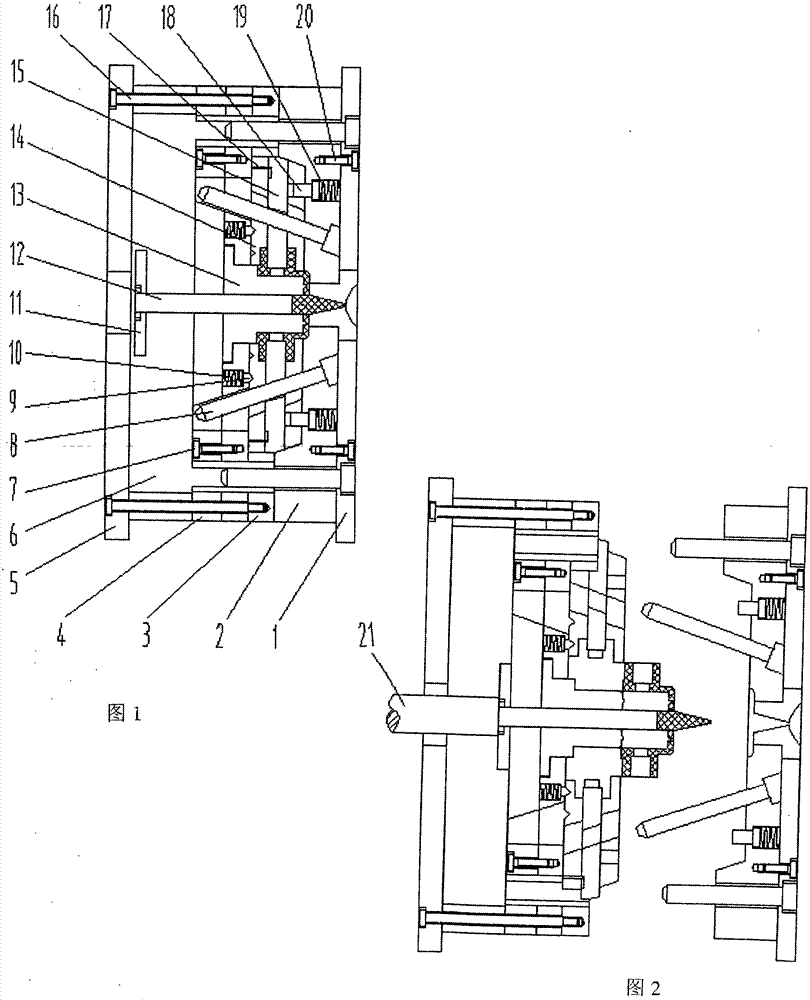

[0016] As shown in the figure, it is the die-casting mold for the upper shell of the automobile engine and the second-stage core-pulling. The point of this model is: for products with bosses and inner holes on the outer wall of metal die-casting parts, if we use existing molds for these products It is very difficult to complete the core-pulling of the boss on the side wall of the product and the inner hole after molding. If the existing technology is used to complete the core-pulling, the product will be pulled or broken from the outer boss. The core pulling is done manually, the production efficiency is extremely low, and the safety of workers cannot be guaranteed. In order to achieve the purpose of mobile demoulding of products, I combine years of experience in mold design, and specially adopt the delayed core-pulling principle of sliders and inclined guide pillars; the mechanism of sliders is installed in the mold sliders to complete this difficult core-pulling action. . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com