Split type die sleeve for straight die shank

A split-type, die-sleeve technology, applied in the field of stamping die parts, can solve the problems of incompatibility of dies, inconvenient production, poor versatility, etc., and achieve the effect of simple structure, cost saving, and tight fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

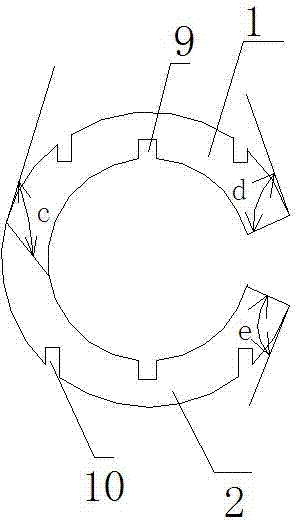

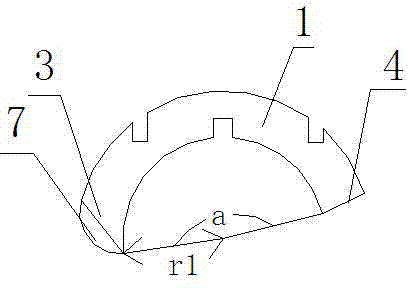

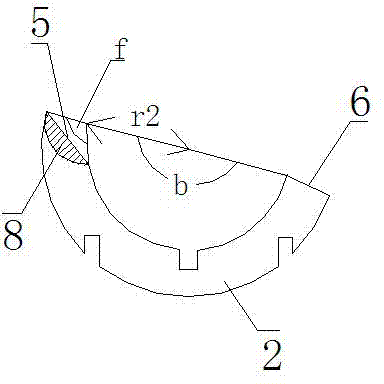

[0020] As shown in the figure, a split die set for a straight die handle includes a first die set 1 and a second die set 2, the first die set 1 and the second die set 2 are split structures, and the first die set 1 and the second die set 2 are split structures. The cross section of the first die set 1 and the second die set 2 is a circular arc structure, and the radius r1 of the first die set 1 = the radius r2 of the second die set 2, and the radian a of the first die set 1 = the second die set 2, the two sides of the first mold case 1 are respectively the first contact surface 3 and the first gap surface 4, and the two sides of the second mold case 2 are respectively the second contact surface 5 and the second gap Surface 6, the first contact surface 3 and the second contact surface 5 are arranged in parallel, the angle between the first contact surface 3 and the tangent l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com