Edible oil plasticizer removing method

A technology for edible oil and plasticizer, which is applied in the field of removing impurities in edible oil and removing plasticizer in edible oil, achieving the effects of low cost, low cost and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

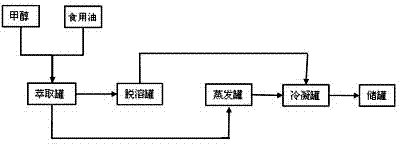

Image

Examples

Embodiment 1

[0016] ①Material mixing: Weigh 500kg of peanut oil (the residual amount of DBP is 0.93 mg / kg, the content of BBP is 0.35 mg / kg, and the content of DiDP is 0.52 mg / kg after testing the plasticizer index), add an equivalent amount of methanol, and use The pump pumps the peanut oil from the lower part of the extraction tank to the upper part of the tank, sprays it on the methanol layer, and the metered peanut oil is circulated 20 times;

[0017] ②Material separation: then stand still for 5 hours to allow the peanut oil and methanol to separate completely in layers;

[0018] ③Desolventization of edible oil: Use a pump to pump peanut oil into the precipitation tank, heat the peanut oil to vaporize part of the methanol dissolved in the oil and separate it from the oil;

[0019] ④Methanol recovery: The separated methanol gas enters the methanol condenser, condenses into a liquid and then flows into the methanol storage tank for recycling. After all the peanut oil in the extrac...

Embodiment 2

[0022] ①Material mixing: Weigh 500kg of peanut oil (after testing the plasticizer index, it is found that the residual amount of DBP is 0.63 mg / kg, the content of BBP is 0.15 mg / kg, and the content of DiDP is 0.22 mg / kg), add 2 times the weight of methanol, Use a pump to pump peanut oil from the lower part of the extraction tank to the upper part of the tank, spray it on the methanol layer, and measure the peanut oil to be circulated 15 times;

[0023] ②Material separation: then stand still for 10 hours to allow the peanut oil and methanol to separate completely in layers;

[0024] ③Desolventization of edible oil: Use a pump to pump peanut oil into the precipitation tank, heat the peanut oil to vaporize part of the methanol dissolved in the oil and separate it from the oil;

[0025] ④Methanol recovery: The separated methanol gas enters the methanol condenser, condenses into a liquid and then flows into the methanol storage tank for recycling. After all the peanut oil in...

Embodiment 3

[0028] ①Material mixing: Weigh 500kg of rapeseed oil (the residual amount of DBP is 0.56 mg / kg, the content of BBP is 0.32 mg / kg, and the content of DiDP is 0.38 mg / kg after testing the plasticizer index), add 5 times the weight of For methanol, the rapeseed oil is pumped from the lower part of the extraction tank to the upper part of the tank, sprayed onto the methanol layer, and the metered rapeseed oil is circulated 15 times;

[0029] ②Material separation: then stand still for 10 hours to allow the peanut oil and methanol to separate completely in layers;

[0030] ③ Edible oil desolventization: Pump the rapeseed oil into the desolventization tank, heat the rapeseed oil to vaporize part of the methanol dissolved in the oil and separate it from the oil;

[0031] ④Methanol recovery: The separated methanol gas enters the methanol condenser, condenses into a liquid and then flows into the methanol storage tank for recycling. After all the rapeseed oil in the extraction tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com