A water-proof socket

An anti-splashing and socket technology, applied in the base/casing, electrical components, coupling devices, etc., can solve the problems of unusable, easy to infiltrate the main body of the socket, easy to appear shallow water, etc., to achieve excellent anti-splashing water. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

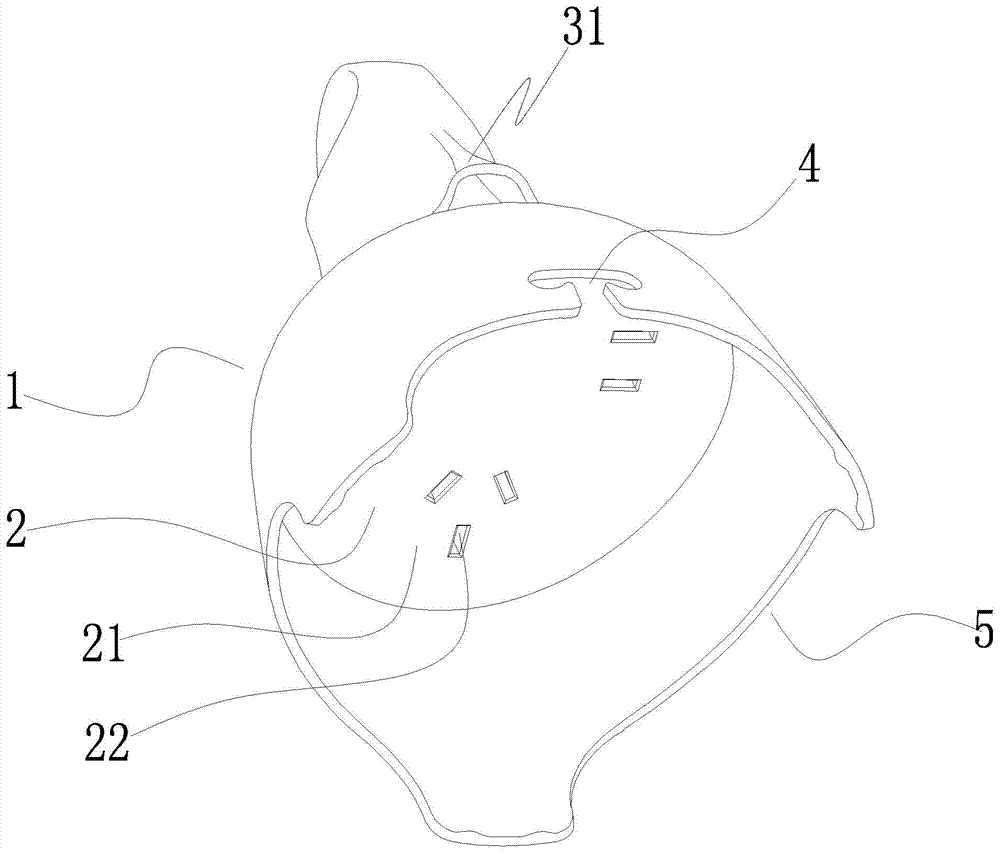

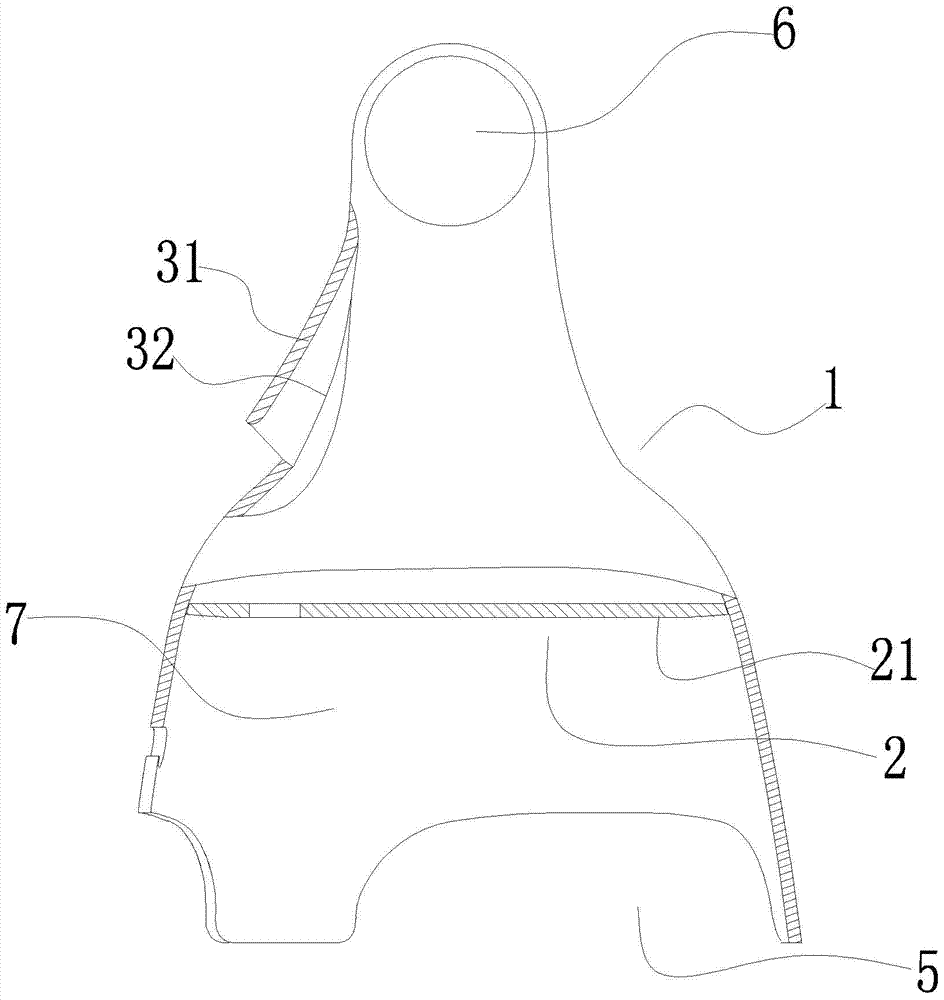

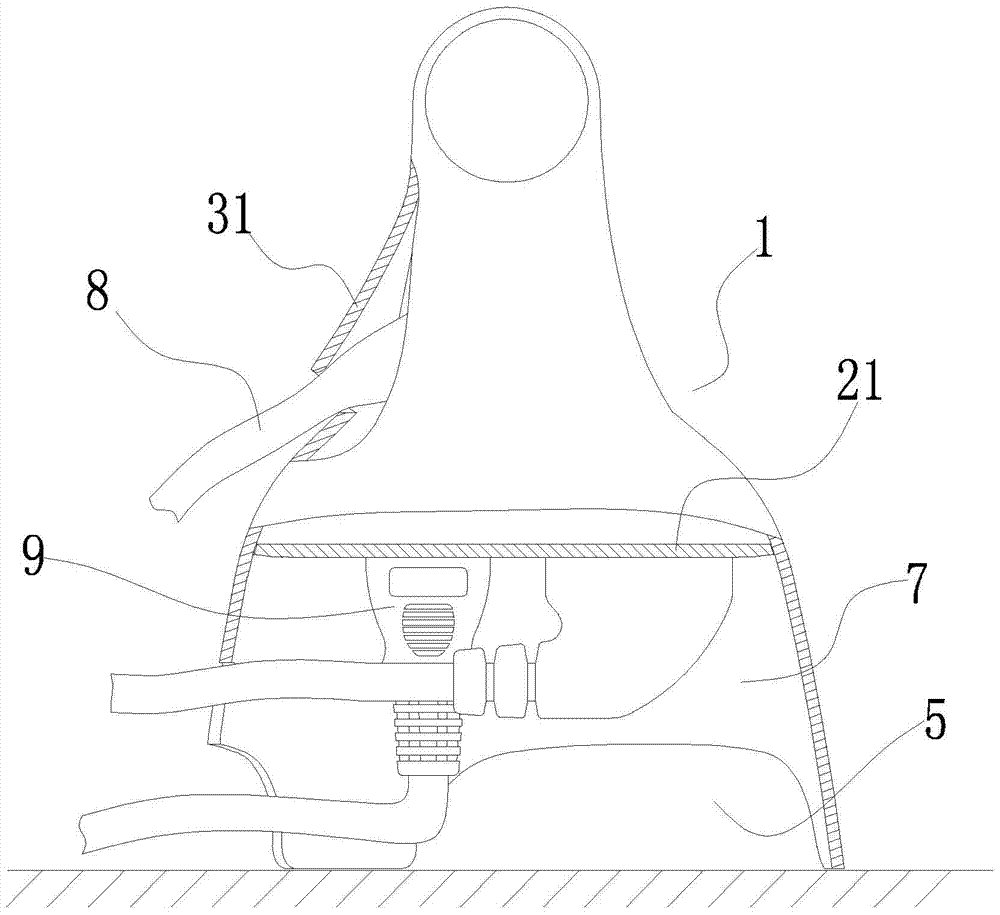

[0035] Embodiment 1: as figure 1 , figure 2 , image 3 As shown, a water-proof socket includes a socket cover body 1 with a closed upper end and an open lower end, a socket main body 2 and a socket power cord 8 arranged in the socket cover body. The lower end of the socket cover is used to support the anti-splash socket. The socket cover is integrally formed. The socket cover body is in the shape of a bell jar. The cross section of the socket cover is circular, and the cross section of the socket cover gradually increases from top to bottom. The top of the socket cover is provided with a hanging hole 6 . The bottom edge of the outer surface of the socket cover is provided with at least one wire-passing gap 5; the bottom edge of the socket cover outer surface in this embodiment is provided with three circumferentially evenly distributed wire-passing gaps, and the gap between two adjacent wire-passing gaps The socket cover forms the resting feet. At least one of the thre...

Embodiment 2

[0040] Embodiment 2: the remaining structure of this embodiment is with reference to embodiment 1, and its difference is:

[0041] like Figure 4 As shown, the socket cover body includes a socket cover main body 1 a and a wiring cover 1 b located above the socket cover main body. The upper and lower ends of the main body of the socket cover are open. The upper opening edge of the main body of the socket cover is provided with an inwardly extending annular limiting plate 12 , and the inner edge of the annular limiting plate is provided with an upwardly extending annular mounting sleeve 13 . The socket body is located in the socket cover body. Three circumferentially evenly distributed first counterbores 14 are provided on the annular limiting plate, and first connecting bolts are provided in each first counterbore. First bolt holes matched with the first connecting bolts are arranged on the jack panel. The jack panel is installed on the annular limiting plate, and the jack ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com