3D orthopedic insole manufacturing method

A production method and technology for insole, which are applied in the directions of manufacturing auxiliary devices, special data processing applications, instruments, etc., can solve the problems of time-consuming processing, waste of material resources, and long-term replacement, and achieve the effect of improving accuracy and reducing errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The invention provides a method for making a 3D orthopedic insole, comprising the following steps:

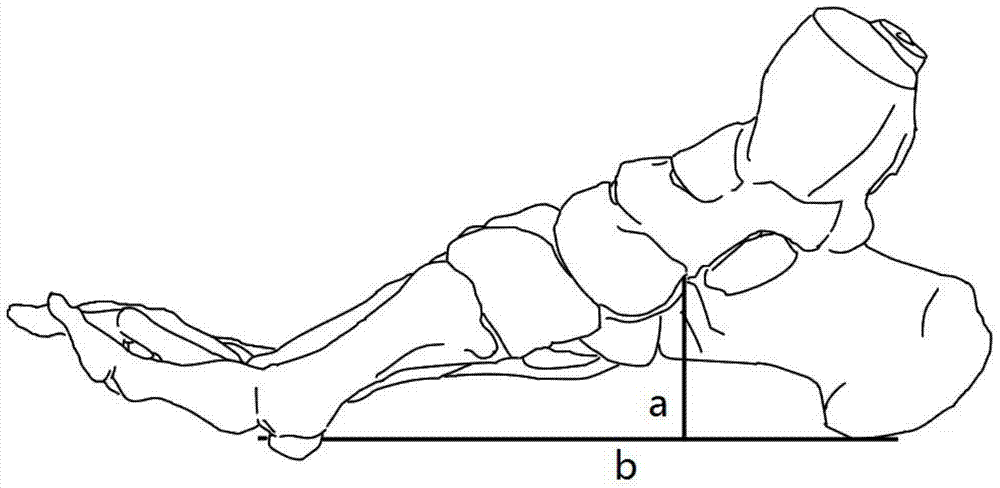

[0039] (1) Imaging examination of the ankle in the weight-bearing position, or imaging examination of the non-weight-bearing position of the corrected ankle;

[0040] (2) Import the scanned image into a three-dimensional modeling software to generate a three-dimensional model of the foot bone and foot;

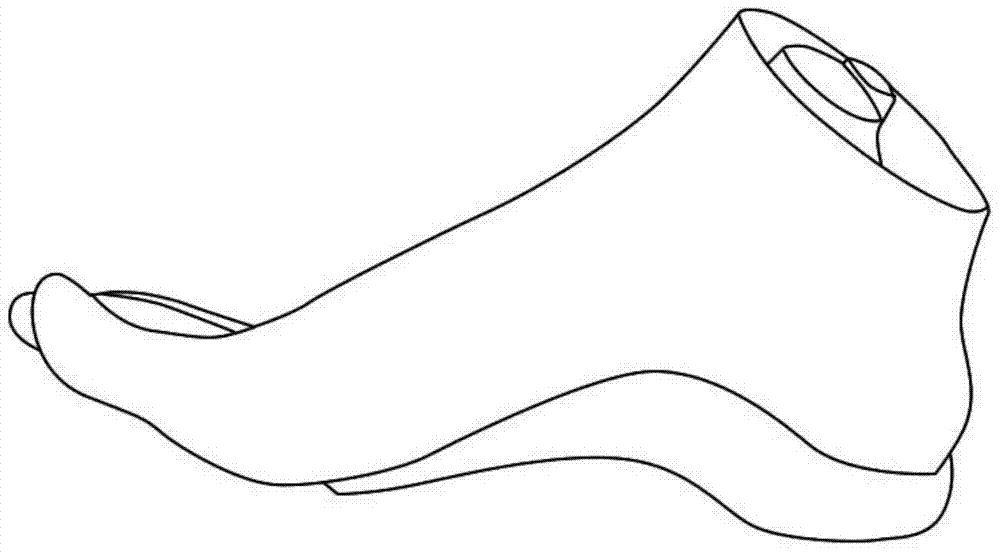

[0041] (3) According to the three-dimensional model of the foot, the curved surface of the insole that fits the sole of the foot is derived;

[0042] (4) according to the three-dimensional model of the foot bone and the specific type of the foot bone, the curved surface of the insole is corrected to obtain the curved surface of the shoe pad after the correction;

[0043] (5) Print out the insole corresponding to the curved surface of the insole after the orthopedic by a 3D printer.

[0044] It scans the 3D model of the user's foot, then deduces the surface of the insol...

Embodiment 2

[0061] A method for making a 3D orthopedic insole, comprising:

[0062] (1) Imaging examination of the ankle in the weight-bearing position, or imaging examination of the non-weight-bearing position of the corrected ankle;

[0063] (2) Import the scanned image into a three-dimensional modeling software to generate a three-dimensional model of the foot bone and foot;

[0064] (3) Manually analyze the type of foot bone, and confirm that the type of foot bone is simple arch collapse, arch collapse with calcaneus valgus, and foot arch collapse with calcaneus valgus and midfoot abduction, and dislocation of the talonavicular joint A sort of;

[0065] (4) According to the three-dimensional model of the foot, the curved surface of the insole that fits the sole of the foot is derived;

[0066] (5) Correct the curved surface of the insole according to the three-dimensional model of the foot bone and the specific type of the foot bone, and obtain the curved surface of the insole after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com