Dynamic mined ore grade refining method using deposit modeling system

A technology of grade and ore deposit, which is applied in the field of refining dynamic grade of mining by using ore deposit modeling system, can solve problems such as the inability to meet the requirements of digital mines, and achieve the effect of reasonable ore blending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

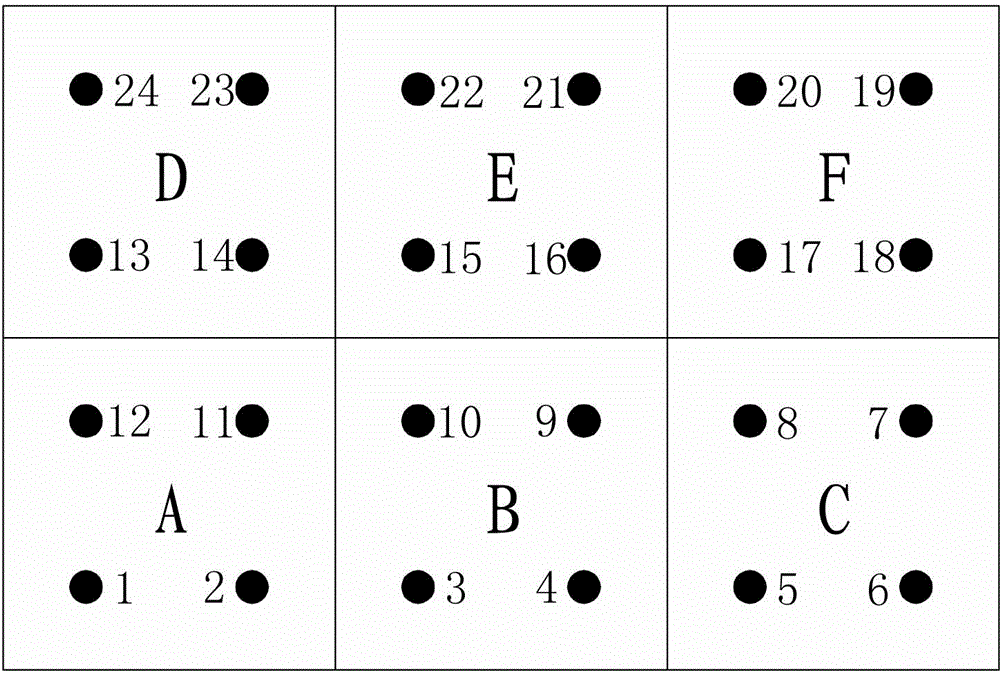

[0028] The technical content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0029] Such as figure 1 As shown, a method for refinement of mining dynamic grade by adopting ore deposit modeling system of the present invention is characterized in that it includes adopting ore deposit modeling system, and using GPS positioning system to form mining dynamic grade refinement according to the electric shovel operation area. module, output the output grade,

[0030] The ore deposit modeling system is composed of a geological survey module, a core sampling module, an assay module and a mining grade model;

[0031] The geo-survey module is used to store the coordinate measurement mark data collected by the geo-surveyors in real time with the total station, to form a list of drill hole coordinates and different batches of drill hole coordinates, and to The hole location coordinate marking results are transmitted to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com