Heat exchanger with vortex pair type squarely arranged heat transferring vortex array

A square heat exchanger technology, applied in the field of vortex array heat transfer vortex array heat exchanger, can solve the problems of fluid flow momentum and energy loss, heat transfer coefficient reduction, flow resistance increase, etc., to achieve convenient design Effect of layout and fabrication, enhanced heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

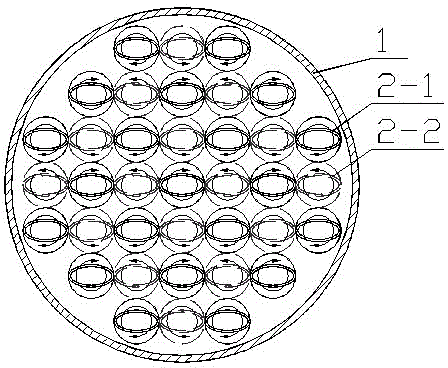

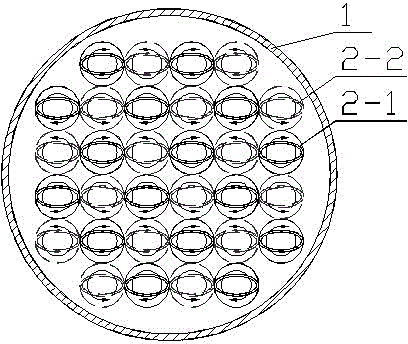

[0014] A paired vortex type heat transfer vortex array heat exchanger in a square arrangement, comprising a shell 1, and a heat transfer core 2 is arranged inside the shell, and the heat transfer core is composed of columnar heat transfer vortexes arranged in a square array , and the contours of adjacent heat transfer vortices are tangent, and the size, spiral lead and spiral phase of the heat transfer vortexes are the same; the heat transfer vortexes are divided into right-handed heat transfer vortex 2-1 and left-handed For the heat transfer vortex body 2-2, the helical directions of any two adjacent heat transfer vortex bodies are opposite, and the arbitrary adjacency includes left-right adjacency and up-down adjacency.

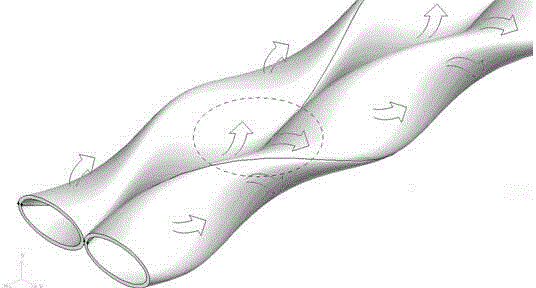

[0015] In the paired vortex square heat transfer vortex array heat exchanger, the flow direction of the fluid flowing around any internal heat transfer vortex body 2 is the same as that of the fluid flowing around the adjacent heat transfer vortex body 2 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com