Dynamic optimization and parameter estimation integrated method based on load prediction

A technology of dynamic optimization and parameter estimation, applied in warm-up, calculation, electrical digital data processing, etc., can solve the problem that the control effect cannot meet the production safety requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

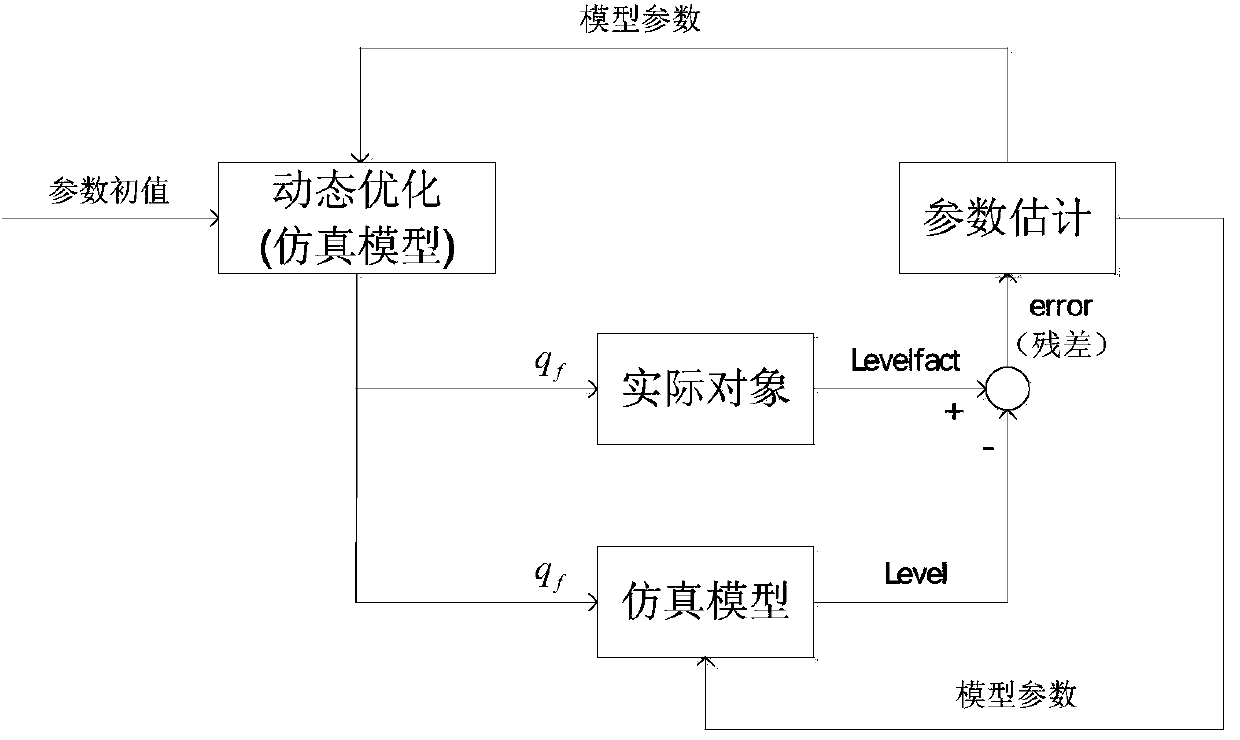

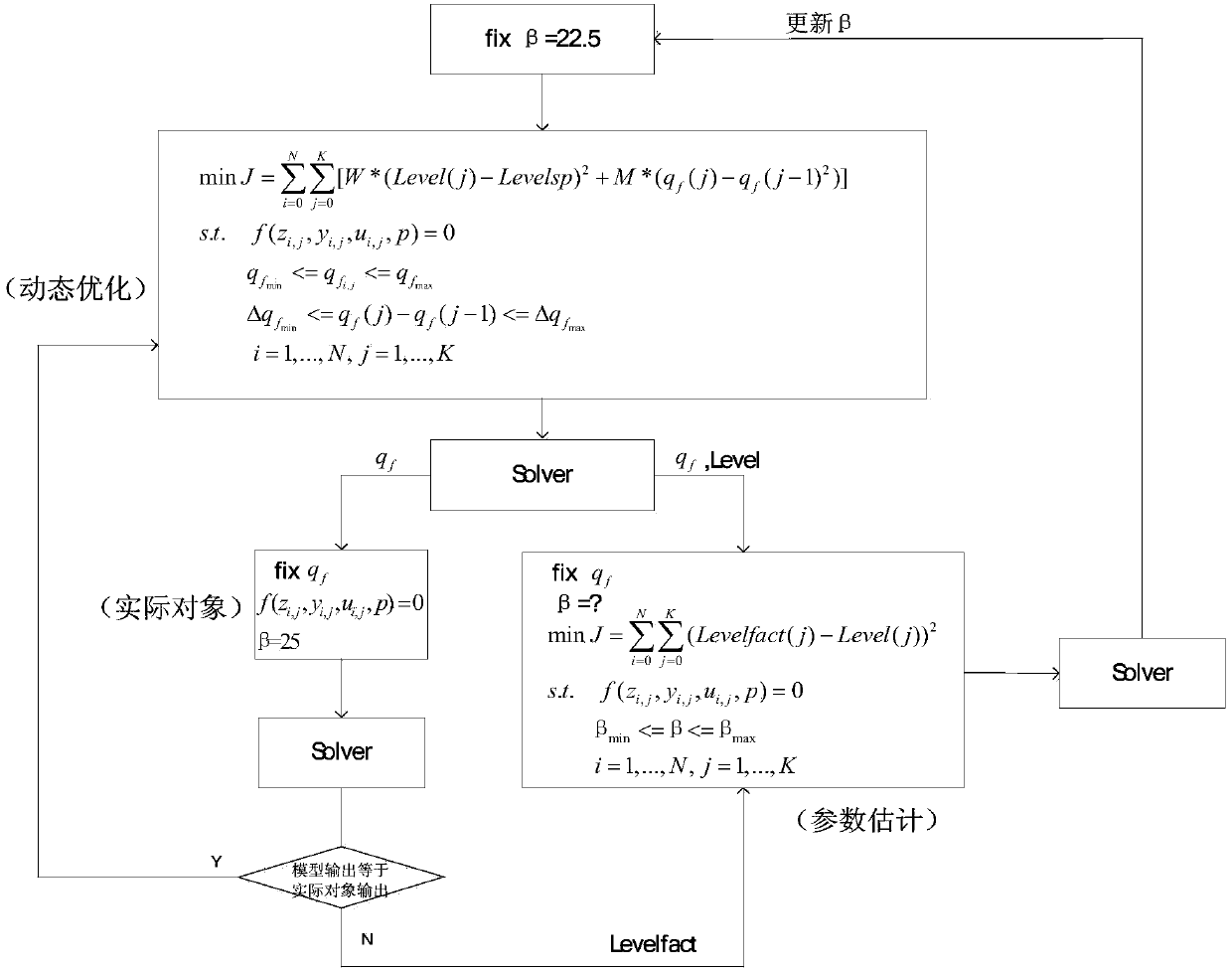

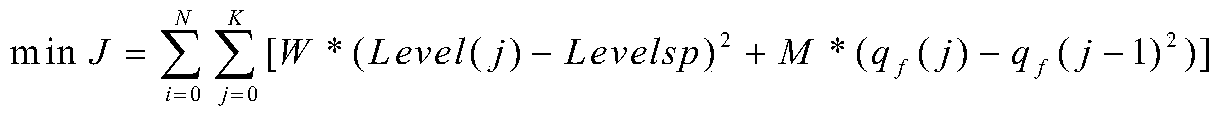

[0034] The working process of the method of the present invention is as figure 1 , 2 Shown:

[0035] Step (1). The specific boiler object selected in this example is the Swedish P16-G16 160MW thermal power unit. based on The fourth-order model, the full simultaneous simulation model of the boiler steam-water system is established under AMPL. The discretization method used in this example is the finite element orthogonal configuration method.

[0036] The size of the model after discretization is related to the number of finite elements and the number of configuration points. The number of finite elements used in this example is 50, and each finite element has 3 configuration points. The entire simulation time is 1500s, and at t=150s A large step change occurs in the steam load.

[0037] Step (2). At t=0s, it is known that the steam load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com