Magnetic side pressure internal control screw spring clutch

A technology of spring clutch and screw rod, which is applied in the direction of magnetic drive clutch, clutch, non-mechanical drive clutch, etc., can solve the problem of inability to achieve high transmission efficiency of gear transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

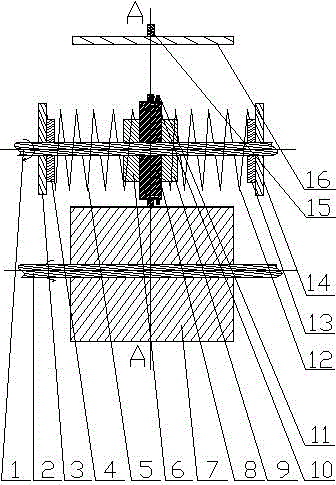

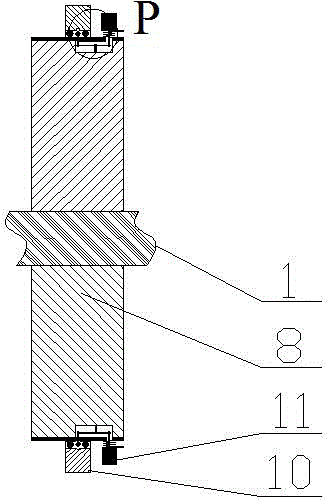

[0021] exist Figure 1-7 In the shown embodiment: the magnetic side pressure internal control screw spring clutch includes a driven shaft 1 with external thread and a driven shaft wheel 8 screwed on the driven shaft 1, and the outer circumference center of the driven shaft wheel 8 has a Passive live wheel 10, passive shaft wheel 8 outer circumferences of passive live wheel 10 sides are symmetrically installed with a plurality of clutch magnetic blocks 35, each clutch magnetic block 35 is connected with a clutch seesaw device 18 by a clutch seesaw bar, each The clutch seesaw device 18 has a clutch seesaw wheel 30 in the area of the inner torus of the passive live wheel 10, and there are a plurality of passive live wheel inner grooves matching the clutch seesaw 30 in the inner torus of the passive live wheel 10 34, the left secondary wheel 6, the left buffer wheel 4, the left retaining wheel 3 and the left spring 5 are arranged on the left side of the passive shaft wheel 8, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com