Mechanical seal for rotary shell pump

A technology of mechanical seals and rotary casing pumps, which is applied in the direction of mechanical equipment, pumps, pump components, etc., can solve the problems of difficult seal design, limited axial size, etc., meet the requirements of function and installation, compact seal structure, shorten shaft effect on space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

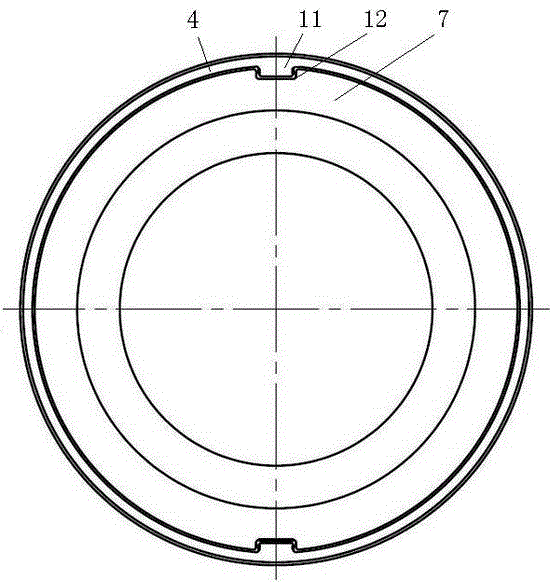

[0014] Such as picture As shown in 1 and 2, the present invention includes a non-compensating ring 1, a compensating ring 3, a compensating ring seat 4, a spring 5, and a spring seat 7, and the non-compensating ring 1, compensating ring 3, and compensating ring seat 4 are set on the pump shaft , the compensation ring 3 adopts an embedded structure and is embedded on the compensation ring seat 4. The sealing structure does not need to use a push ring, which reduces the number of parts and shortens the axial space. The spring seat 7 is set on the compensation ring seat 4, a spring 5 is installed between the two, and the spring 5 compensates for the entire seal. The non-compensating ring 1 is located on the pump shaft, and is pressed on the shaft shoulder of the pump shaft by locking devices such as lock nuts. The spring seat 7 and the pump body are prevented from rotating through the installation pin 10, the compensation ring seat 4 is provided with a lug 11, and the spring sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com