An integral cylinder body of liquid-cooled type internal combustion engine and a mould for manufacturing thereof

A technology of overall structure and cylinder block, which is applied in the direction of manufacturing tools, casting molds, cylinders, etc., and can solve the problems of uneven cooling and symmetry of cylinders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

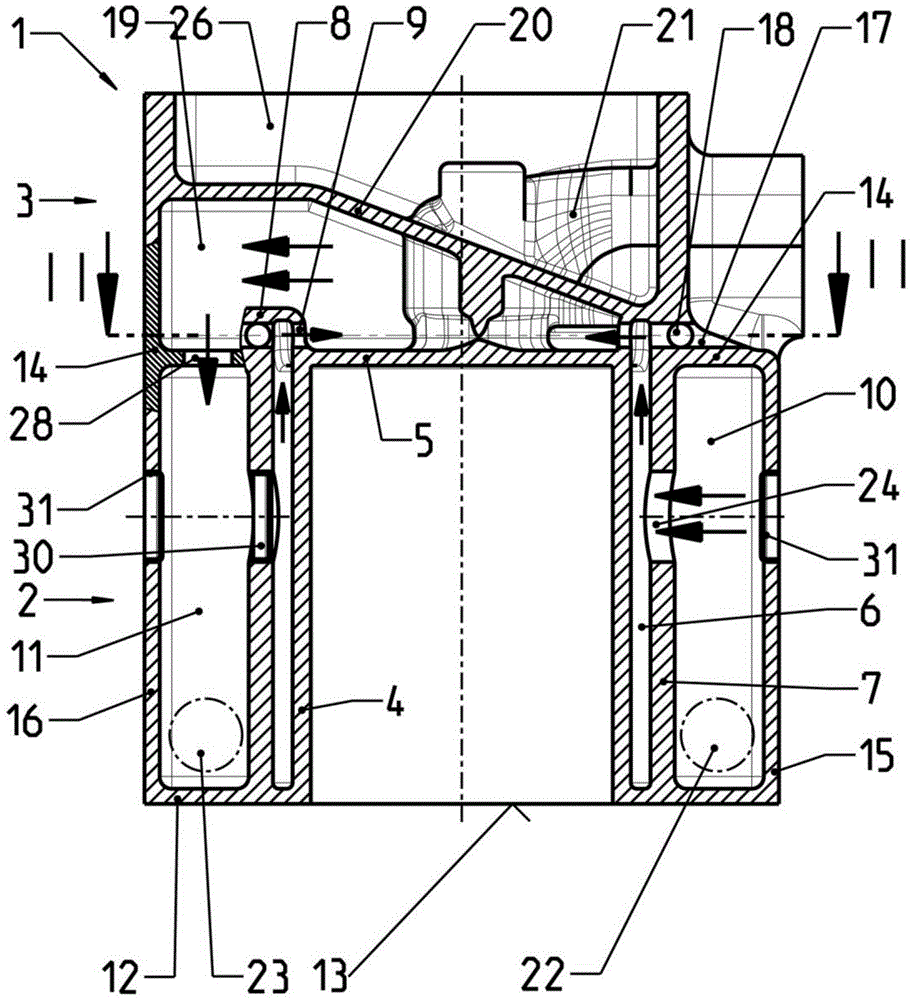

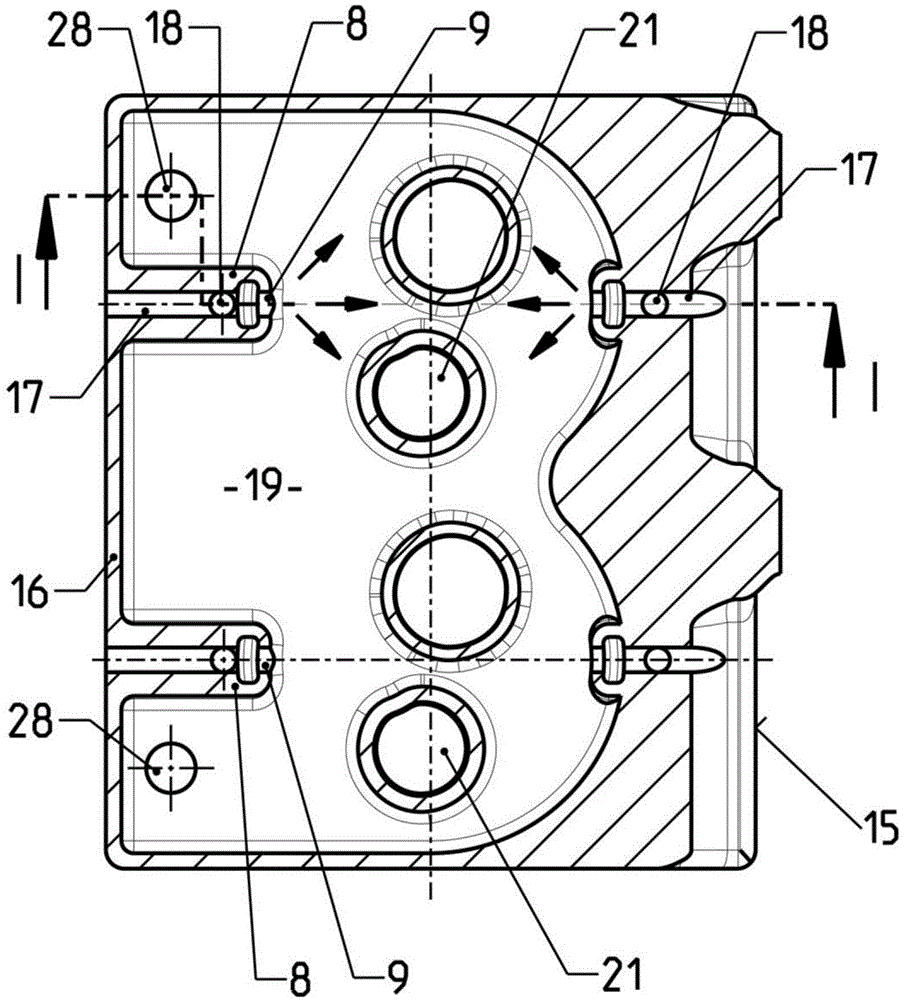

[0025] exist figure 1 , the cylinder block is generally designated by reference numeral 1. The cylinder block 1 includes a cylinder part 2 and a cover part 3 integrally formed therewith. The cylinder part 2 includes several cylinders which are respectively composed of cylinder walls 4 and cylinder bases 5 . The circumference of the cylinder wall 4 is jointly washed by a first cooling water cavity 6 , and the first cooling water cavity 6 is surrounded by a cooling jacket 7 . The cylinder wall 4 , the cooling water cavity 6 and the cooling jacket 7 protrude from the cylinder seat at least at one point and form a raised portion 8 with a horizontal discharge hole 9 there. As used herein, the term "cooling water" refers to any cooling liquid.

[0026] The cooling jacket 7 constitutes the side wall on the cylinder side of the ducts whose surfaces extend in the longitudinal direction of the cylinder block 1 . exist figure 1 Among them, the distribution pipe 10 is constructed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com