Rectangular staggered joint shield based capping segment and post segment assembling structure and method

A rectangular shield and segment technology, which is used in vertical shaft equipment, earth-moving drilling, wellbore lining, etc., can solve the problems of segment fragmentation, difficulty in controlling the opening angle of rings and longitudinal joints, and long time, and achieve a relatively high gap. Easy to control, improve splicing strength and sealing, high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

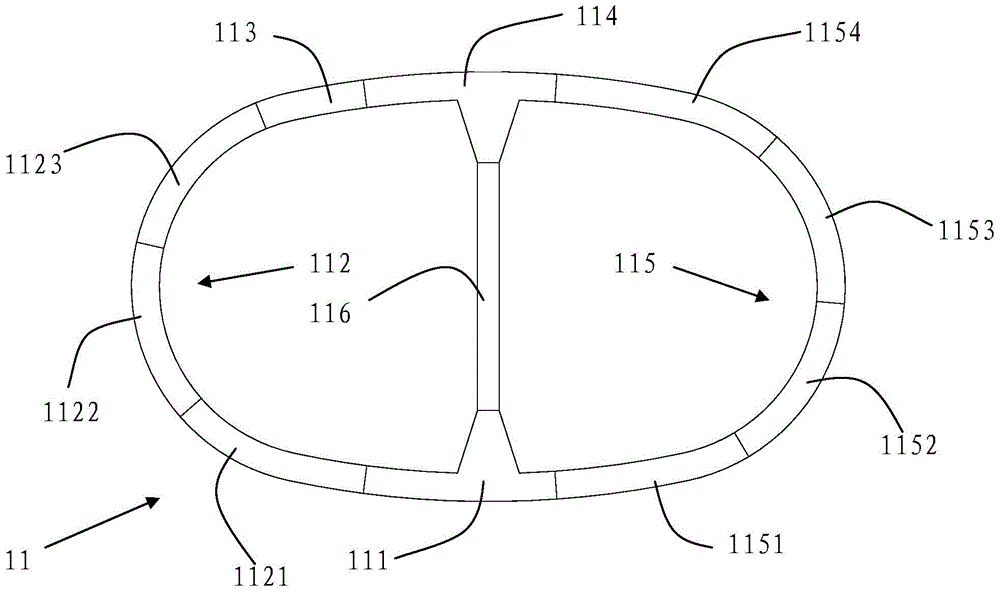

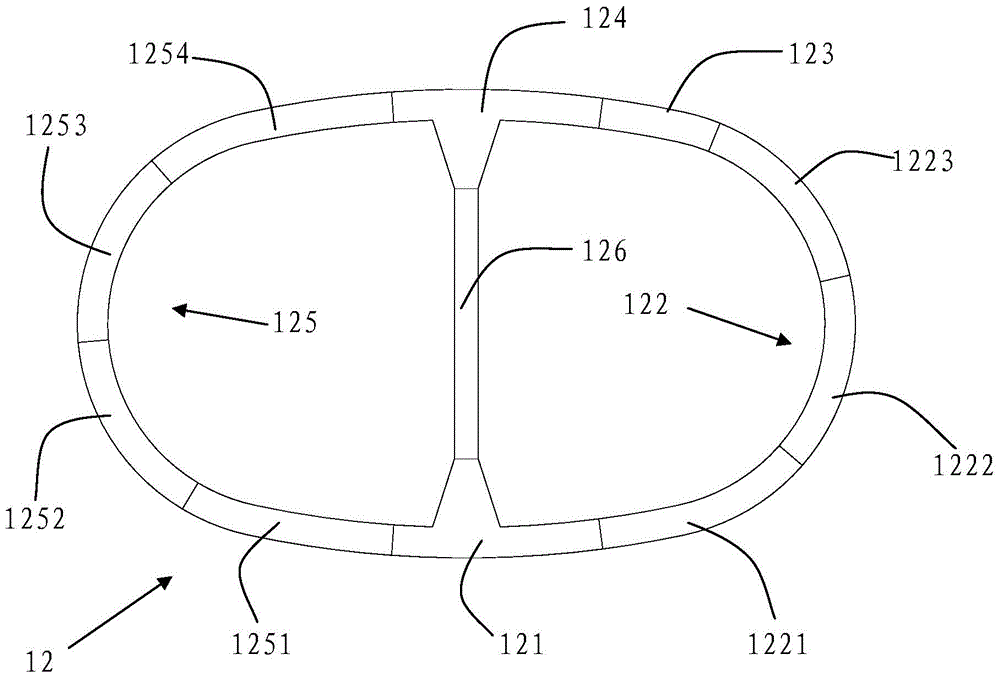

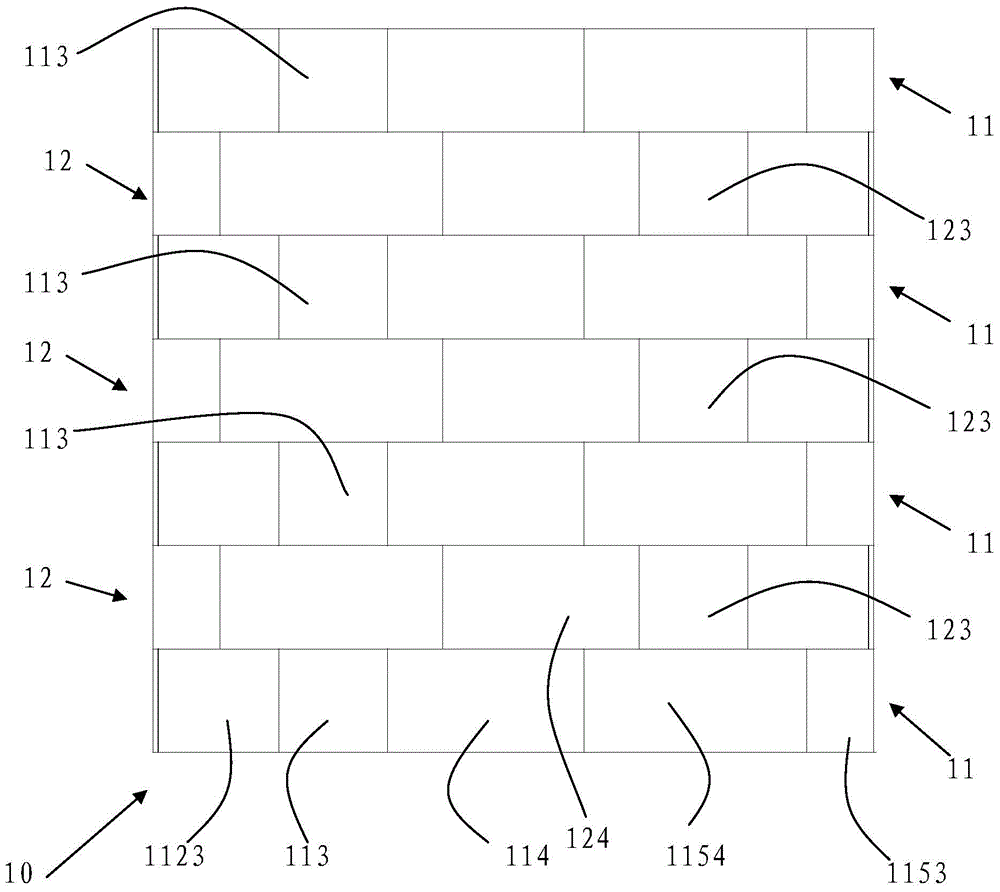

[0072] see first Figure 1~3 As shown, an example is given of an assembly scheme for the overall assembly of the staggered rectangular shield segment by using the assembling method of the capping segment and column segment of the staggered rectangular shield of the present invention. In this assembly scheme, the overall segment assembly 10 is mainly composed of alternately spliced first segment lining rings 11 and second segment lining rings 12, and the first segment lining ring 11 and the second segment lining ring 12 connected by bolts.

[0073] like figure 1 As shown, the first segment lining ring 11 is composed of 11 segments spliced together, the ring width is 1200mm, and the thickness is 450mm, including the first lower T-shaped segment 111, the first left waist segment 112, the first A top segment 113, a first upper T-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com