A kind of anti-broken pressure-sensitive adhesive and preparation method thereof

A technology of pressure-sensitive adhesive and glue breaking, applied in the direction of adhesive type, ester copolymer adhesive, etc., can solve problems such as tensile fracture, and achieve the effect of reducing the amount of glue applied, stabilizing the product, and simplifying the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of an anti-glue breaking pressure-sensitive adhesive, comprising the following steps:

[0032] 1) Preparation of functional monomer polytetrahydrofuryl acrylate;

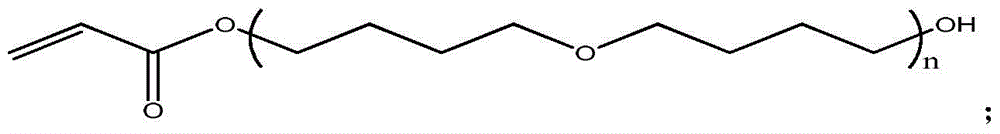

[0033] The polytetrahydrofuran ether diol that number average molecular weight is 600 is dissolved in dichloromethane, and the concentration of polytetrahydrofuran ether diol in dichloromethane is 20wt%, is added dropwise in the reaction of acrylic acid chloride, polytetrahydrofuran ether diol and The molar ratio of acrylic acid chloride is 1:1, the reaction temperature is 10°C, and the reaction time is 2 hours. During the reaction, triethylamine is used to absorb the hydrogen chloride gas generated during the reaction. The molar ratio of triethylamine to acrylic acid chloride is 1:1 The reaction product generates polytetrahydrofuryl acrylate through extraction separation, vacuum distillation and vacuum drying, and the molecular structural formula of polytetrahydrofuryl acrylate is:

[0...

Embodiment 2

[0042] A preparation method of an anti-glue breaking pressure-sensitive adhesive, comprising the following steps:

[0043] 1) Preparation of functional monomer polytetrahydrofuryl acrylate;

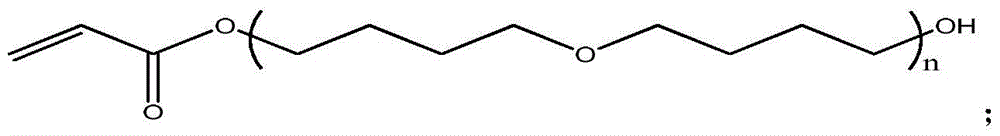

[0044] Dissolve polytetrahydrofuran ether diol with a number average molecular weight of 2000 in dichloromethane, the concentration of polytetrahydrofuran ether diol in dichloromethane is 30wt%, and then dropwise add it to acrylic acid chloride to react, polytetrahydrofuran ether diol and acrylic acid The molar ratio of acid chloride is 1.3:1, the reaction temperature is 30°C, and the reaction time is 3h. During the reaction, triethylamine is used to absorb the hydrogen chloride gas generated during the reaction. The molar ratio of triethylamine to acrylic acid chloride is 1:1; The reaction product is separated by extraction, vacuum distillation and vacuum drying to generate polytetrahydrofuryl acrylate. The molecular structural formula of polytetrahydrofuryl acrylate is:

[0045]

[...

Embodiment 3

[0052] A preparation method of an anti-glue breaking pressure-sensitive adhesive, comprising the following steps:

[0053] 1) Preparation of functional monomer polytetrahydrofuryl acrylate;

[0054] The polytetrahydrofuran ether diol that number average molecular weight is 1000 is dissolved in dichloromethane, and the concentration of polytetrahydrofuran ether diol in dichloromethane is 25wt%, is then added dropwise in the reaction of acrylic acid chloride, polytetrahydrofuran ether diol and The molar ratio of acrylic acid chloride is 1.2:1, the reaction temperature is 20°C, and the reaction time is 2.5h. During the reaction, triethylamine is used to absorb the hydrogen chloride gas generated in the reaction process. The molar ratio of triethylamine to acrylic acid chloride is 1: 1; The reaction product is separated by extraction, vacuum distillation and vacuum drying to generate polytetrahydrofuryl acrylate, and the molecular structural formula of polytetrahydrofuryl acrylate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com