Printing solution for forming friction-reducing layer of sliding bearing, preparation method and application thereof

A technology of sliding bearings and anti-friction layers, applied in the direction of bearing components, shafts, bearings, coatings, etc., can solve problems such as high wear rate and failure to meet new technical requirements, and achieve avoiding fatigue cracks and good tribological properties , good lipophilic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

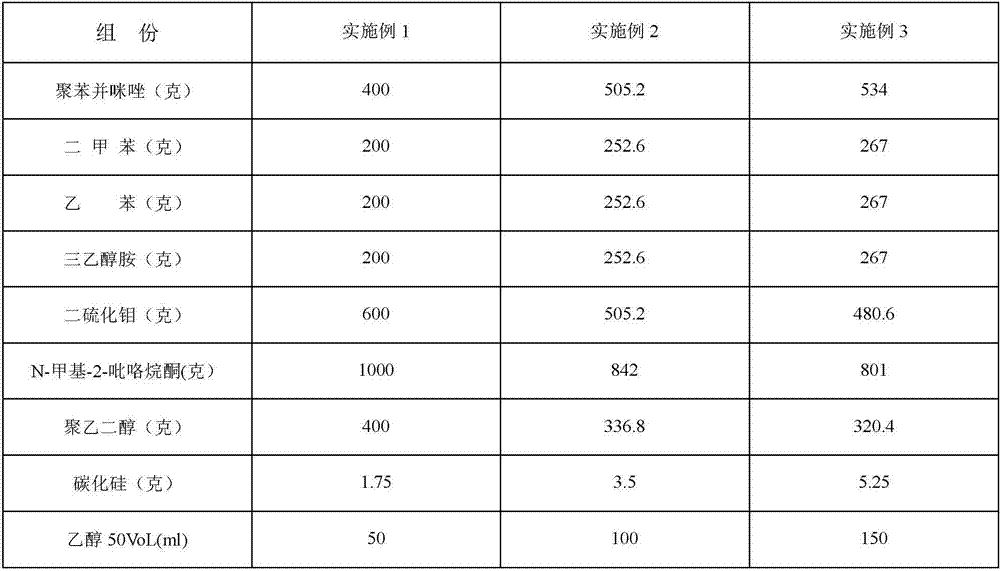

Embodiment 1

[0061] A kind of printing liquid that is used to form sliding bearing antifriction layer of the present embodiment is made up of following components by weight part (100g per part):

[0062] 10 parts of polybenzimidazole resin solution

[0063] Molybdenum disulfide solution 20 parts

[0064] Silicon carbide powder solution 0.5 parts

[0065] Specifically, the printing solution described in this embodiment is prepared according to the following steps:

[0066] 1) Preparation of polybenzimidazole resin solution: polybenzimidazole resin, xylene, ethylbenzene and triethanolamine were mixed and stirred according to the weight ratio of 2:1:1:1. Specifically, in 400g polybenzimidazole resin, add 200g xylene and 200g ethylbenzene as diluent and dilute, obtain polybenzimidazole resin dilution 800g, then add 200g triethanolamine to disperse as dispersant, after conventional stirring Prepare polybenzimidazole resin solution 1000g;

[0067] 2) Preparation of molybdenum disulfide solut...

Embodiment 2

[0075] A kind of printing liquid that is used to form sliding bearing antifriction layer of the present embodiment is made up of following components by weight part (40g per part):

[0076] 30 parts of polybenzimidazole resin solution

[0077] Molybdenum disulfide solution 40 parts

[0078] Silicon carbide powder solution 2.5 parts

[0079] Specifically, the printing solution described in this embodiment is prepared according to the following steps:

[0080] 1) Preparation of polybenzimidazole resin solution: polybenzimidazole resin, xylene, ethylbenzene and triethanolamine were mixed and stirred according to the weight ratio of 2:1:1:1. Specifically, add 252.6g xylene and 252.6g ethylbenzene in 505.2g polybenzimidazole resin and dilute as diluent, obtain polybenzimidazole resin dilution 1010.4g, then add 252.6g triethanolamine as dispersant and disperse 1263g of polybenzimidazole resin solution was obtained after conventional stirring;

[0081] 2) Preparation of molybdenu...

Embodiment 3

[0089] A kind of printing liquid that is used to form the sliding bearing antifriction layer of this embodiment is composed of the following components by weight (26.7g per part):

[0090] 50 parts of polybenzimidazole resin solution

[0091] Molybdenum disulfide solution 60 parts

[0092] Silicon carbide powder solution 6 parts

[0093] Specifically, the printing solution described in this embodiment is prepared according to the following steps:

[0094] 1) Preparation of polybenzimidazole resin solution: polybenzimidazole resin, xylene, ethylbenzene and triethanolamine were mixed and stirred according to the weight ratio of 2:1:1:1. Specifically, in 534g polybenzimidazole resin, add 267g xylene and 267g ethylbenzene as diluent and dilute, obtain polybenzimidazole resin diluent 1068g, then add 267g triethanolamine to disperse as dispersant, after conventional stirring Prepared polybenzimidazole resin solution 1335g;

[0095] 2) Preparation of molybdenum disulfide solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com