Foaming agent used for process of making foamed glass from CRT screen glass

A foaming glass and foaming agent technology, applied in the field of foaming agents, can solve the problem of heavy metals such as lead and cadmium polluting soil and water bodies, and achieve the effects of helping optical properties, improving mechanics, and uniform distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

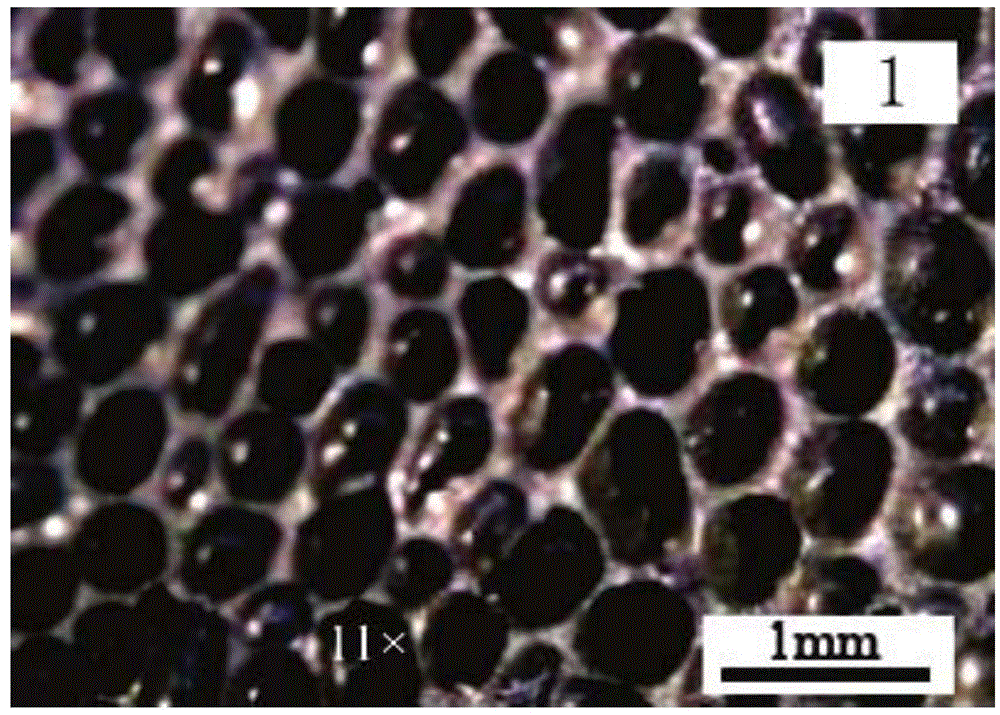

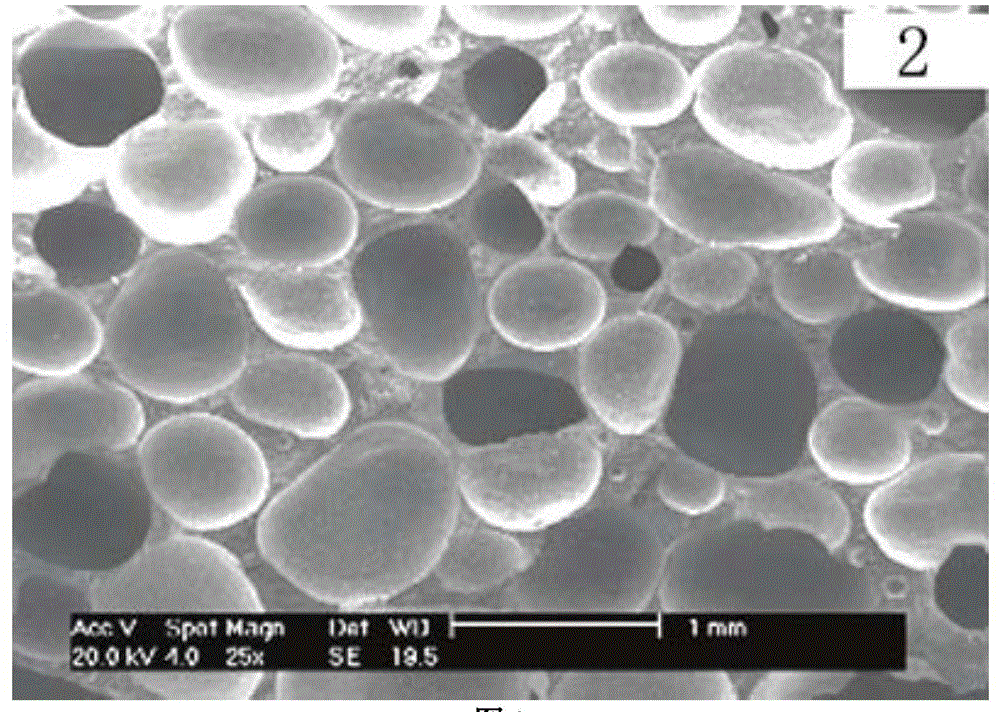

Image

Examples

Embodiment 1

[0018] A foaming agent in the process of manufacturing foamed glass using CRT screen glass:

[0019] Composition: Sb 2 o 3 : 5g, KNO 3 : 25g, CRT screen glass: 60kg.

Embodiment 2

[0021] A foaming agent in the process of manufacturing foamed glass using CRT screen glass:

[0022] Composition: Sb 2 o 3 : 5g, NaNO 3 Weight: 35g, CRT screen glass: 80kg.

Embodiment 3

[0024] A foaming agent in the process of manufacturing foamed glass using CRT screen glass:

[0025] Composition: Sb 2 o 3 : 5g, Mg(NO 3 ) 2 : 25g, CRT screen glass: 7kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com