Filling pipe for filling of high-viscosity fluid

A high-viscosity, fluid technology, used in liquid distribution, transportation or transfer devices, packaging, distribution devices, etc., to achieve the effect of large operating range, resource saving and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

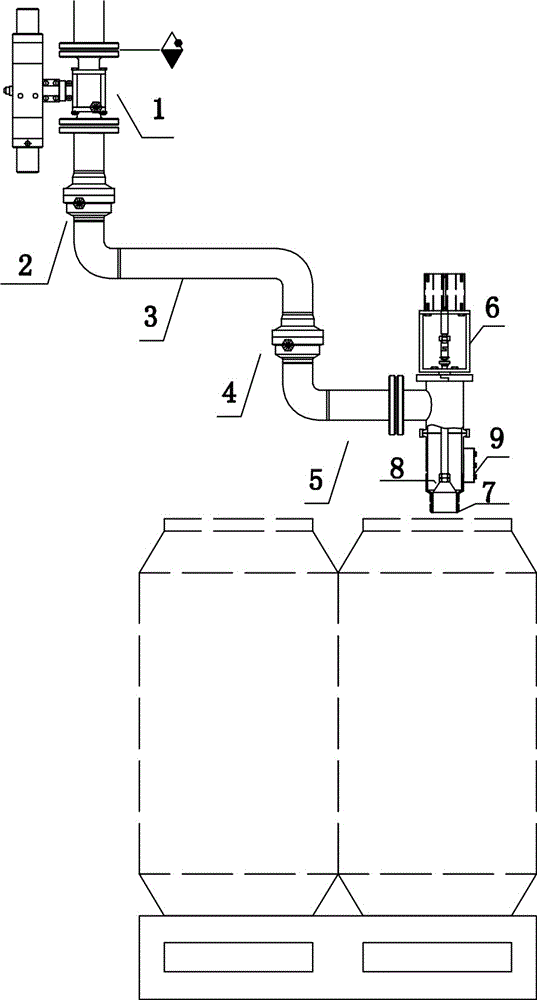

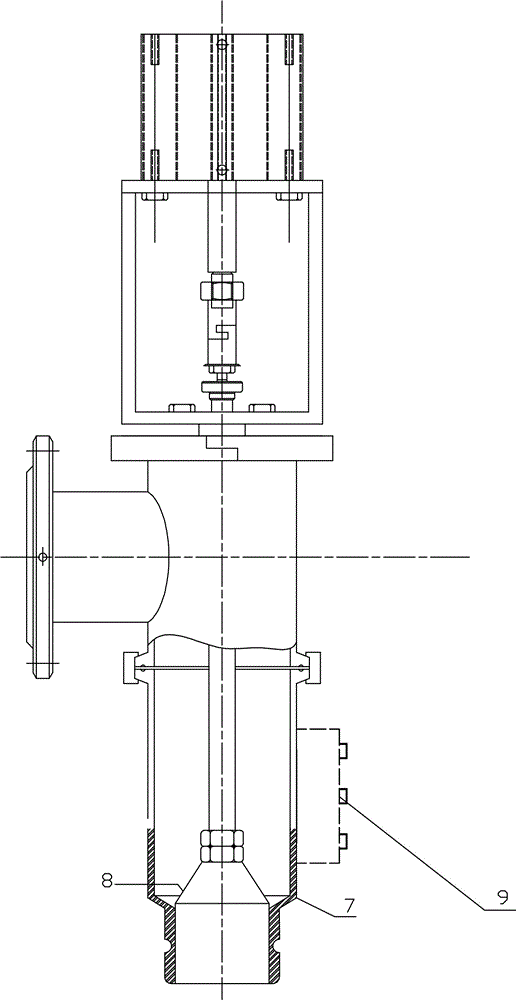

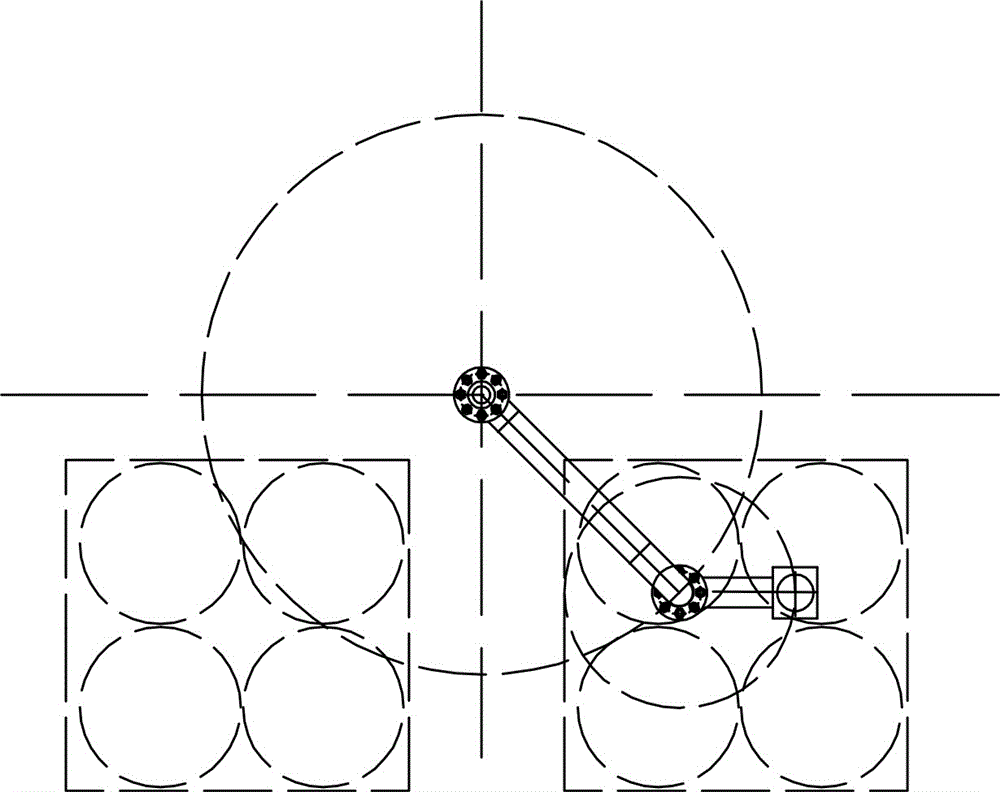

[0019] Such as figure 1 with figure 2 As shown, a crane tube for filling high-viscosity fluids includes a pneumatic ball valve 1, one end of the inner arm 3 is connected to the pneumatic ball valve 1 through the first rotary joint 2, and the other end of the inner arm 3 is connected to the outer tube through the second rotary joint 4. The arm 5 is connected, the end of the outer arm 5 is connected with the spray gun 7 with the pneumatic head 6, and the cover mouth 8 of the spray gun 7 is connected with the pneumatic head 6.

[0020] Pneumatic ball valve 1 is a pneumatic ball valve installed on the feed pipe.

[0021] Spray gun 7 is a large diameter spray gun.

[0022] The caliber of spray gun 7 is Φ89mm.

[0023] Cover mouth 8 is telescopic cover mouth.

[0024] Control box 9 is installed on spray gun 7 sides. The switches of the pneumatic ball valve 1 and the spray gun 7 are controlled by the side-mounted control box 9. Under normal circumstances, the pneumatic head 6 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Caliber | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com