A fully automatic collecting machine

A fully automatic, tubular machine technology, applied to labeling machines, labels, winding strips, etc., can solve problems such as not being able to satisfy manufacturers, affecting equipment work efficiency, and unfavorable market competitiveness, so as to improve work efficiency and The effect of improving work quality, improving market competitiveness and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

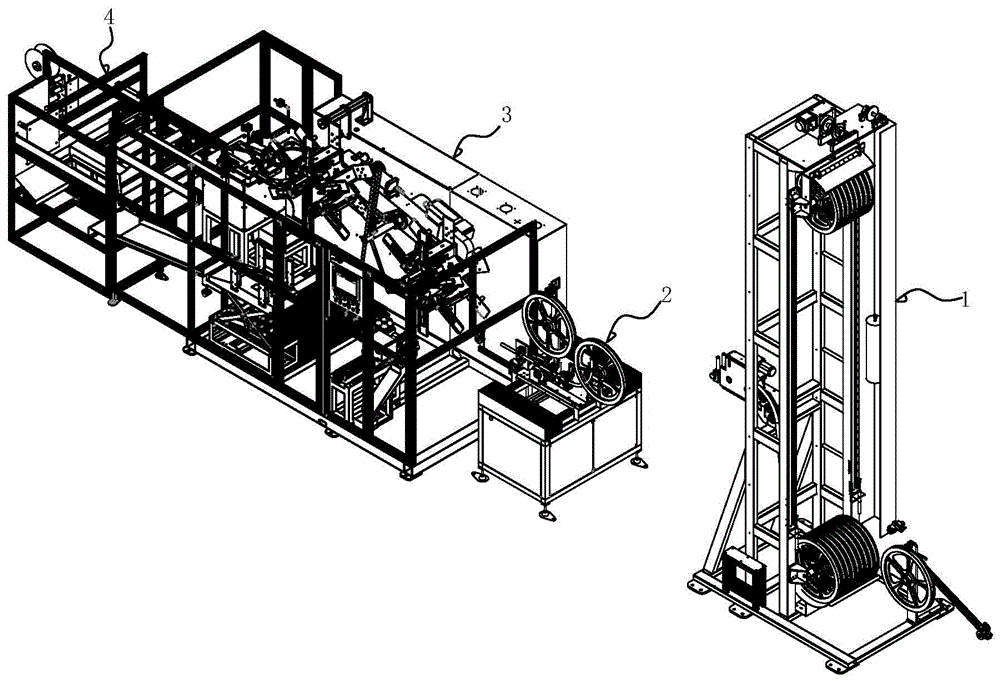

[0037] See Figure 1-10As shown, it is a fully automatic tube collecting machine, which includes a buffer frame structure 1 , a tube arrangement device 2 , a tube coil device 3 and a packaging device 4 .

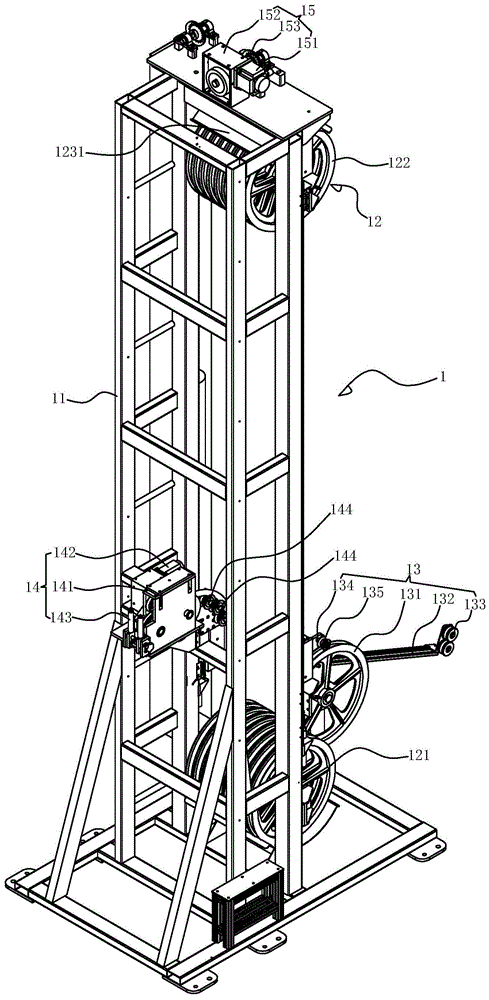

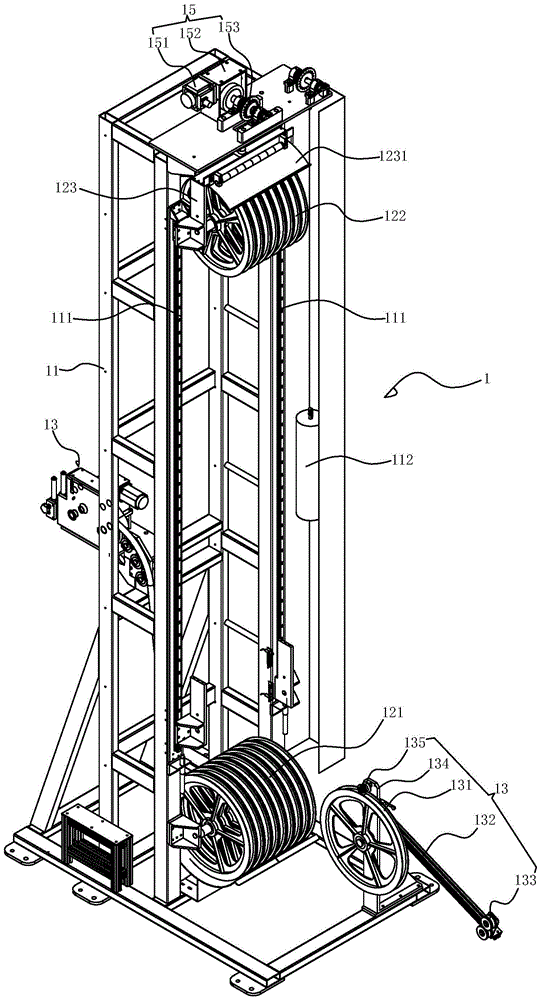

[0038] For details, see Figure 1-2 As shown, the buffer frame structure 1 includes: a first frame 11 , a storage wheel set 12 installed on the first frame 11 , a guiding mechanism 13 , and a traction mechanism 14 for transporting pipe bodies.

[0039] The storage wheel set 12 includes: a lower storage wheel 121 mounted on the lower end of the first frame 11 and an upper storage wheel 122 mounted on the upper end of the first frame 11 and capable of moving up and down in the first frame 11, The upper storage wheel 122 is located directly above the lower storage wheel 121 .

[0040] The first frame 11 is provided with a pair of slide rails 111 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com