A method for preparing granular rubber by continuously extruding desulfurized rubber powder with three screws

A desulfurization rubber powder and three-screw technology, which is applied in the field of waste rubber recycling and reuse, can solve problems such as unresolved air pollution and safety hazards, unsatisfactory use of environmental protection dust removal equipment, and mechanical properties of Mooney viscosity rebound products. To achieve the effect of flexible geometric arrangement, which is conducive to heat dissipation and eliminates smoke pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

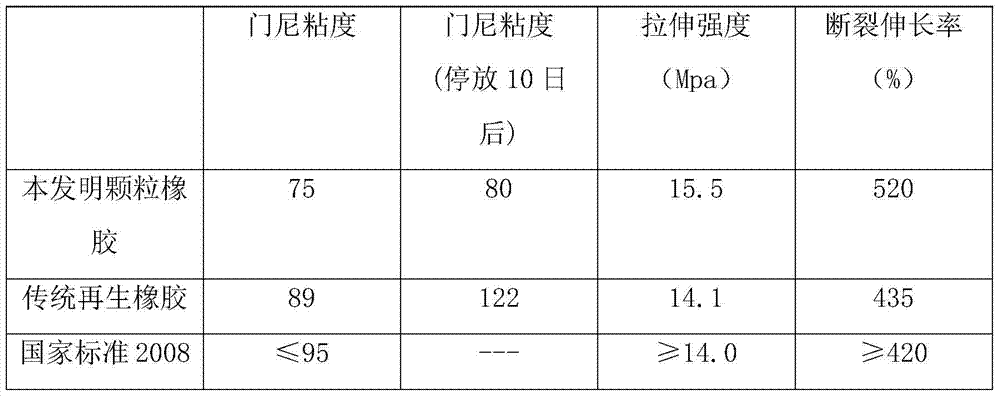

Embodiment 1

[0017] Example 1: The desulfurized rubber powder prepared by preliminary desulfurization of waste tire rubber powder is fed into a co-rotating three-screw extruder arranged in a "one" shape (D=50mm, L / D=48 In: 1), the screw element of the first material conveying section of the three-screw controlled by the cooling device is a forward thread element, the temperature of the barrel is 0°C, the screw element of the pre-shearing section is a combination of a reverse thread element and an engaging block, and the barrel The temperature is at 20°C, the screw element in the second material conveying section is a positive conveying screw element, the barrel temperature is at 25°C, the screw element in the second shearing section is a combination of meshing blocks and toothed mixing blocks, and the barrel temperature is at 35°C, the screw element of the third material conveying section is a combination of the meshing block and the forward conveying screw element, the barrel temperature i...

Embodiment 2

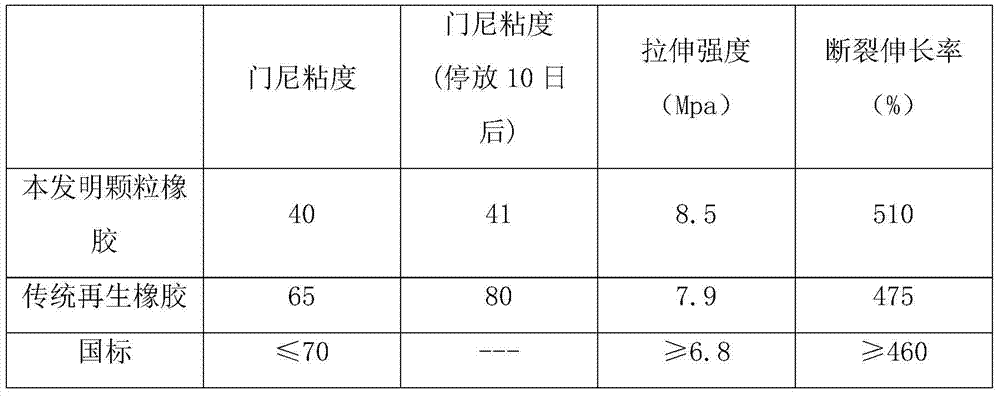

[0020] Example 2: The desulfurized rubber powder prepared by preliminary desulfurization of waste butyl rubber is fed into a co-rotating three-screw extruder arranged in a "one" shape (D=90mm, L / D=30mm) through a conical single-screw feeder : 1) Inside, the screw element of the first material conveying section of the three-screw controlled by the cooling device is a combination of positive thread element and reverse thread element, the temperature of the barrel is 25°C, and the screw element of the pre-shearing section is an engaging block and a positive thread element The combination, the barrel temperature is 40 ° C, the screw element of the second material conveying section is a positive conveying screw element, the barrel temperature is 35 ° C, the screw element of the second shearing section is a combination of meshing block and toothed mixing block , The temperature of the barrel is 55°C, the screw element of the third material conveying section is a positive conveying th...

Embodiment 3

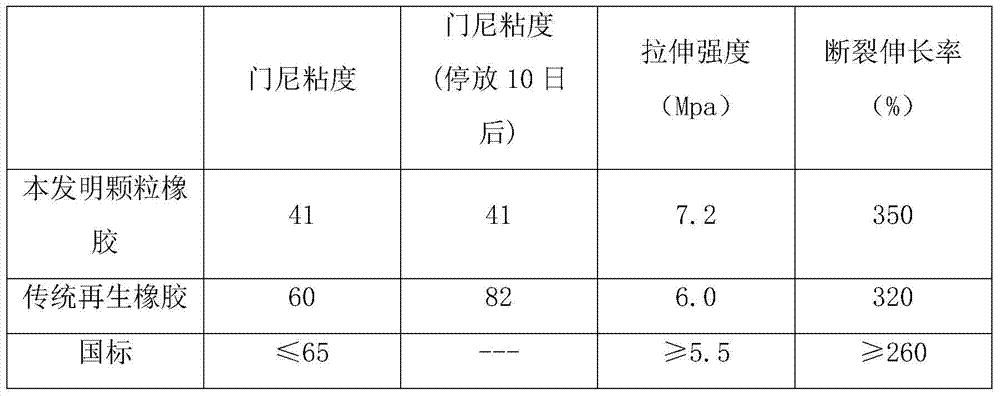

[0023]Example 3: The desulfurized rubber powder prepared by preliminary desulfurization of waste ethylene-propylene rubber is fed into a co-rotating three-screw extruder arranged in the shape of "product" through a single-screw forced feeder (D=150mm, L / D=16: 1) In the first material conveying section of the three-screw controlled by the cooling device, the screw element is a positive thread element, the barrel temperature is 5°C, and the screw element in the pre-shear section is the meshing block, the toothed mixing block and the positive thread element. Combination, the barrel temperature is 5°C, the screw element of the second material conveying section is a positive conveying screw element, the barrel temperature is -5°C, the screw element of the second shearing section is a combination of meshing block and toothed mixing block , The temperature of the barrel is 0°C, the screw element of the third material conveying section is a combination of the forward thread element and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com