Overcurrent protection device

An overcurrent and current technology, applied in circuit devices, circuit devices, circuit thermal devices, etc., can solve the problems of low thermal conductivity and low temperature detection accuracy, and achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

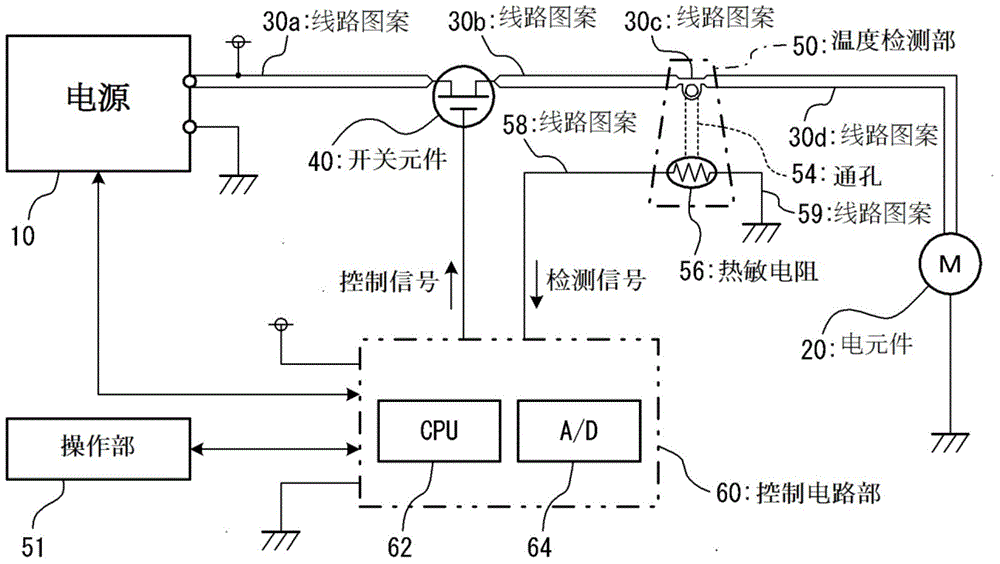

[0024] A first embodiment of the present invention will be specifically described below with reference to the drawings. The overcurrent prevention device of the present invention is suitable for devices that drive components such as DC power generated from supplied commercial power supply, and use the DC power to increase current fluctuations or generate momentary huge currents like a motor or the like.

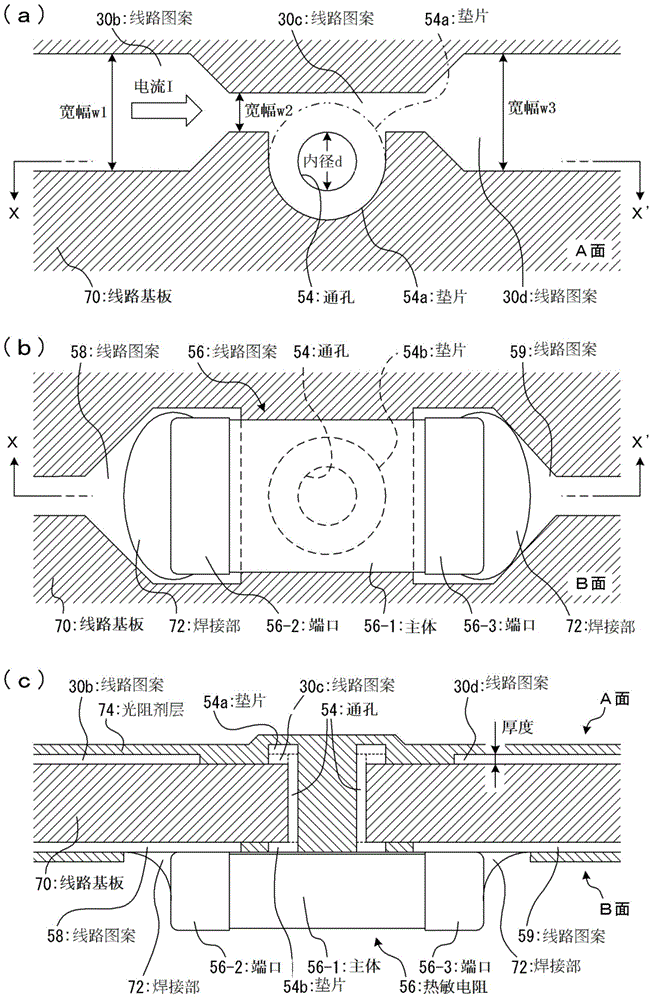

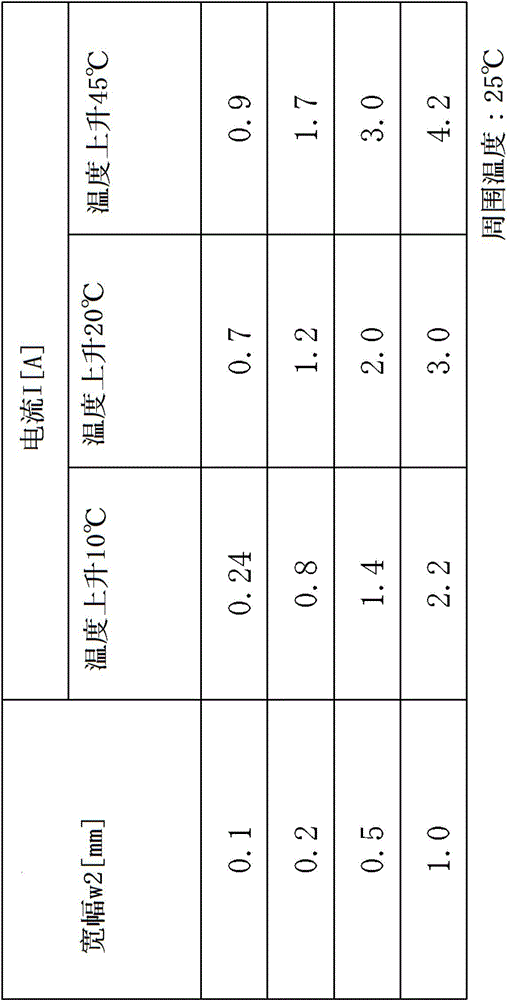

[0025] Such as figure 1 As shown, the present embodiment also utilizes the direct current outputted by the power supply 10 to drive a load such as a motor, that is, a circuit of the electric element 20, but between the power supply 10 and the electric element 20, circuit patterns 30a and 30b (first circuit circuit), The wiring pattern 30c (heating wiring portion) and the wiring pattern 30d (first wiring circuit) are connected. It is assumed that the line patterns 30a, 30b, 30c, 30d will pass a relatively large current, so even in figure 1 On the circuit diagram of the circu...

no. 2 example

[0054] In the first embodiment described above, the circuit board through which current flows is formed with a narrow circuit pattern 30c, and the circuit pattern 30c is used as a heat source to monitor overcurrent. However, it is also possible to form a structure that directly monitors the heat generation of electrical components such as transistors, FETs, semiconductor components, and ICs (Integrated Circuit, integrated circuits).

[0055] Below, use Figure 5 (a) and Figure 5 (b) Describes a structural example in which overcurrent is prevented by monitoring heat generation of electrical components. In addition, in Figure 5 (a) and Figure 5 (b), same as figure 1 or figure 2 (a)~ figure 2 Parts corresponding to the respective parts shown in (c) are denoted by common symbols, and detailed explanations are omitted.

[0056] exist Figure 5 In (a), the direct current output from the power source 10 is supplied to the electric element 20a via the wiring pattern 30a a...

no. 3 example

[0064] Also, use Figure 6 (a) and Figure 6 (b) Another structural example for preventing overcurrent by monitoring heat generation of electrical components is described. Should Figure 6 (a) and Figure 6 (b) will also be the same as figure 1 or figure 2 (a)~ figure 2 (c), Figure 5 (a), Figure 5 Parts corresponding to the respective parts shown in (b) are given common symbols, and detailed description is omitted.

[0065] exist Figure 6 In (a), the direct current output from the power source 10 is supplied to the electric element 20b via the wiring pattern 30a and the switching element 40, the wiring pattern 30b, and the metal terminal 20b-2. The electrical element 20b is also a CPU that generates heat when a large current flows when controlling high-speed processing, and a drive element that generates heat when controlling the current supplied to a load.

[0066] The temperature detection unit 50b is composed of a through hole 54, a thermistor 56, wiring patt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com