High-gain low-scattering angle reflective surface loaded with gradient corrugation

An angle reflective surface and low scattering technology, applied in the direction of electrical components, antennas, etc., can solve the problems of reducing the echo scattering of the angle reflective surface and insufficient gain of the angle reflective surface, so as to reduce the strong scattering characteristics and facilitate phase adjustment , the effect of increasing the gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose of the present invention, the technical problem to be solved and the technical solution clearer, further description will be made below in conjunction with the drawings and specific embodiments.

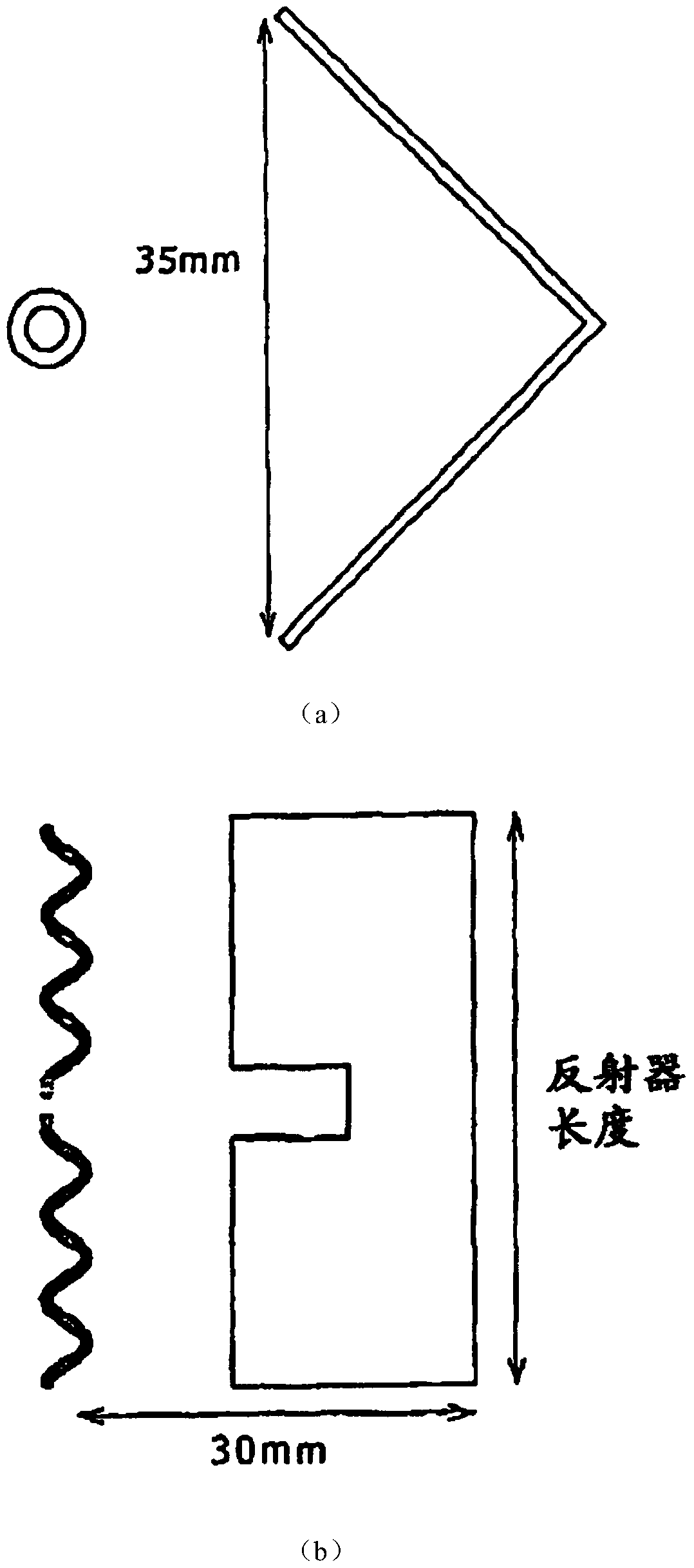

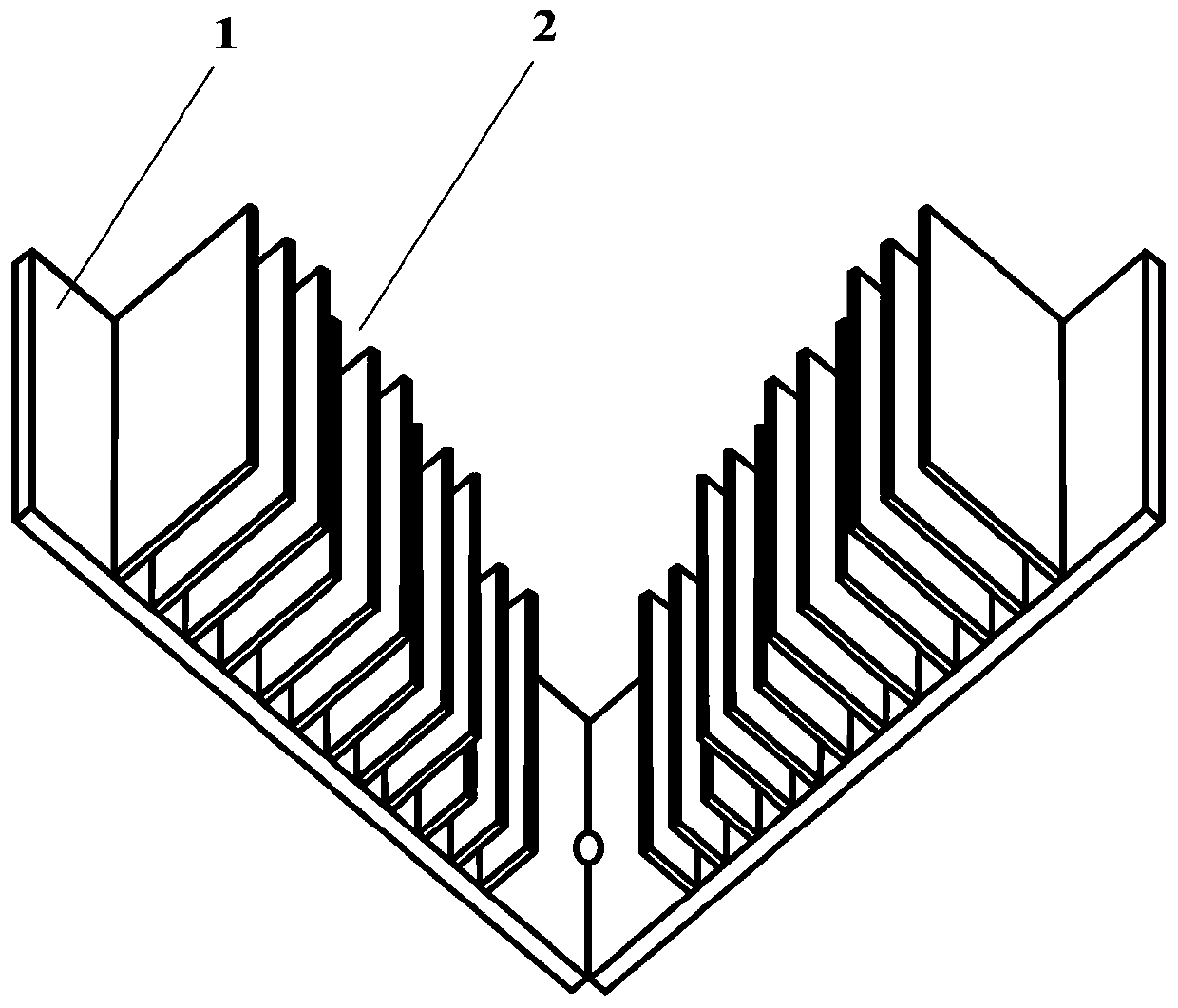

[0023] refer to figure 2 , the present invention includes a reflective surface 1 and a corrugated structure 2 .

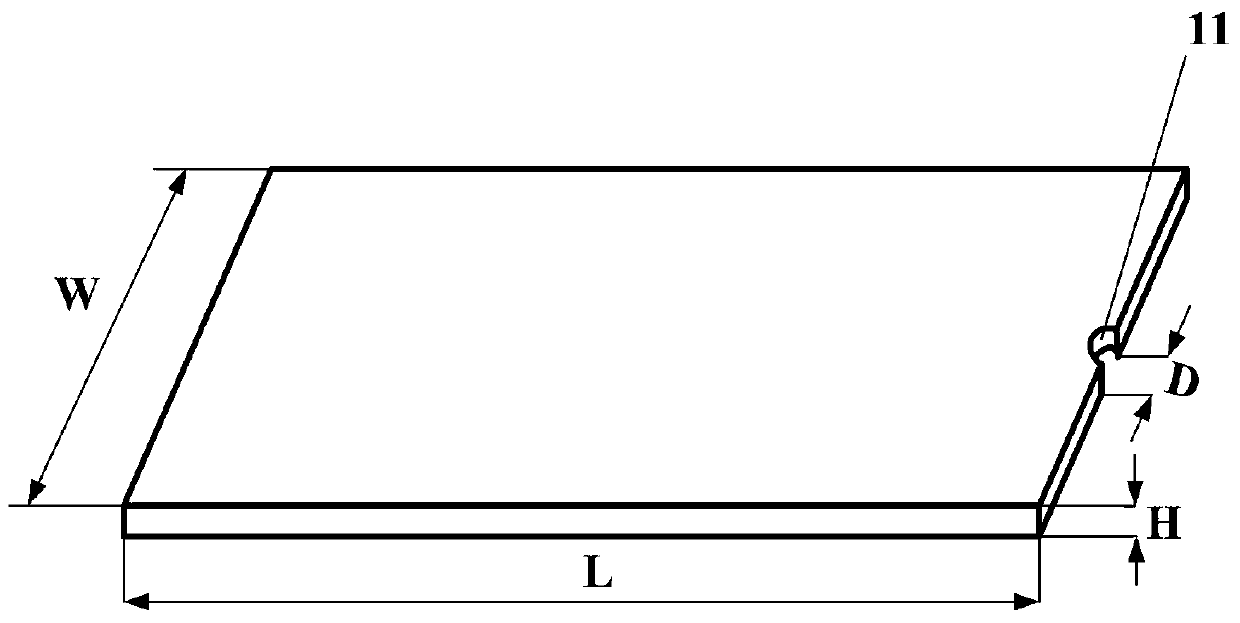

[0024] The reflective surface 1 adopts an L-shaped structure formed by fixed connection of two metal plates 11 with the same specifications and perpendicular to each other; a corrugated structure 2 is arranged on the metal plate 11, and the corrugated structure 2 is located inside the angled surface. It is composed of corrugated sections whose height increases successively from the position close to the included angle to the position away from the included angle. Each group of corrugated sections contains three metal sheets, and the distance between adjacent metal sheets is equal. At the junction of the two metal plates 11, the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com