A Thickness Prediction Method for Compressive Fault Zones in Covering Areas

A prediction method and fault zone technology, applied in the field of oil and gas exploration and development, can solve the problem of lack of effective methods for compressive fault zones, and achieve the effect of accurate prediction results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

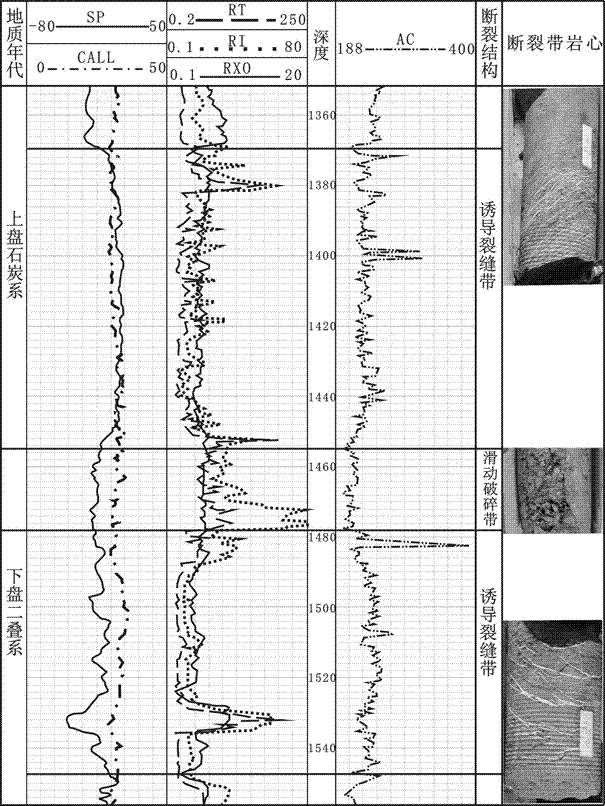

Image

Examples

Embodiment Construction

[0029] The specific embodiments of the present invention are described in detail below.

[0030] The method for predicting the thickness of the compressive fracture zone in the coverage area includes the following steps:

[0031] (1) Judge whether the stress environment in the work area is a compressive environment or a tensile environment. If it is a compressive stress environment, go to step (2);

[0032] (2) Interpret the seismic data at the location of the fault zone, identify the fault, and obtain the vertical stratum fault distance L; the method of obtaining the vertical stratum fault distance L is:

[0033] Fit the average seismic reflection velocity in the study area to obtain the comprehensive velocity according to the geological conditions and characteristics of the study area, and establish the time-depth conversion relationship:

[0034] h=a(e bt -1)

[0035] Where: h—depth, m;

[0036] t—Seismic reflection time, ms;

[0037] a, b—constant (reflecting the shape of the speed c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com