Testing method for anisotropic thermal-expansion coefficient of continuous-fiber-reinforced resin-based composite material

A technology for strengthening resin base and thermal expansion coefficient, applied in the direction of material thermal expansion coefficient, etc., can solve the problems of fragile and easily broken thermal expansion coefficient, and achieve the effect of being conducive to demoulding, avoiding direct contact, and avoiding the introduction of test system errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A test method for the anisotropic thermal expansion coefficient of continuous fiber reinforced resin matrix composites:

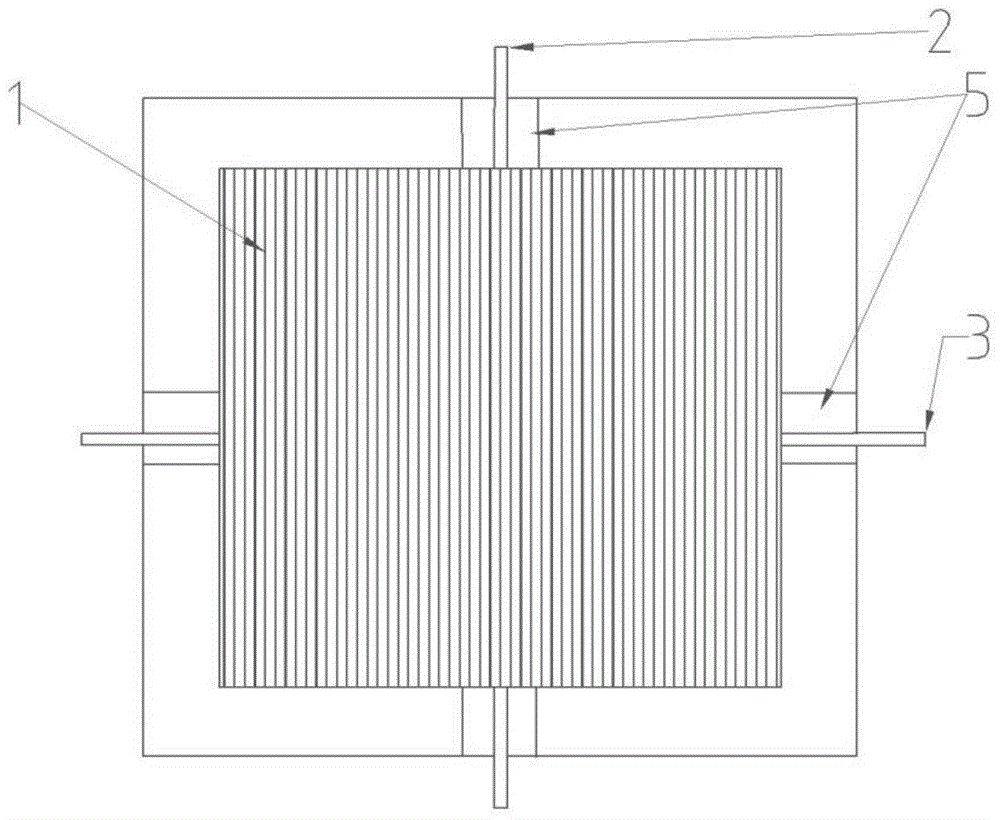

[0038] (1) Preparation of composite material samples: Lay resin-based composite material prepregs in the mold cavity, and lay fiber Bragg grating strings on multiple prepreg layers; that is, on the nth layer (n>5) A plurality of fiber Bragg grating strings 2 are laid in the fiber direction (0° direction), and a plurality of fiber Bragg grating strings 3 are laid in the n+i layer (i>5) perpendicular to the fiber direction (90° direction); different from the 0° direction What is more important is that on the FBG sensor laid in the 90° direction, a small piece of resin-based composite material prepreg 4 needs to be used to embed the grating area up and down, and the fiber direction in this small piece of resin-based composite material prepreg is the same as that of the fiber Bragg grating string. In order to protect the grating area without affecting th...

Embodiment 2

[0050] A test method for the anisotropic thermal expansion coefficient of continuous fiber reinforced resin matrix composites:

[0051] (1) Preparation of composite material samples: Lay resin-based composite material prepregs in the mold cavity, and lay fiber Bragg grating strings on multiple prepreg layers; that is, on the nth layer (n>5) A plurality of fiber Bragg grating strings 2 are laid in the fiber direction (0° direction), and a plurality of fiber Bragg grating strings 3 are laid in the n+i layer (i>5) perpendicular to the fiber direction (90° direction); different from the 0° direction What is more important is that on the FBG sensor laid in the 90° direction, a small piece of resin-based composite material prepreg 4 needs to be used to embed the grating area up and down, and the fiber direction in this small piece of resin-based composite material prepreg is the same as that of the fiber Bragg grating string. In order to protect the grating area without affecting th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com