Method and system for interactive pressure testing of ultra-thin films

A pressure test and ultra-thin film technology, applied in the direction of applying repeated force/pulsation force to test the strength of materials, etc., to achieve simple structure, reasonable design, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solution in the embodiment will be specifically, clearly and completely described below in conjunction with the drawings in the embodiment.

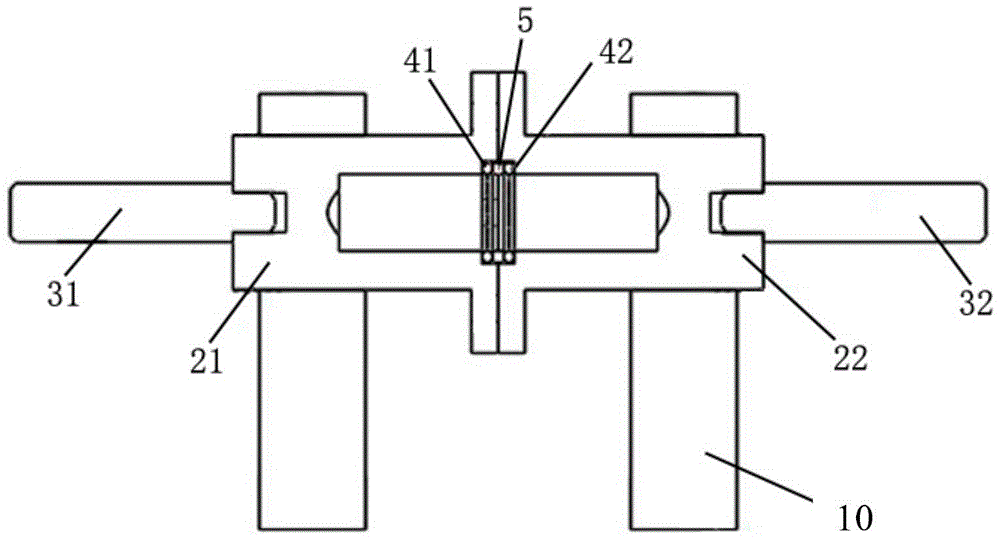

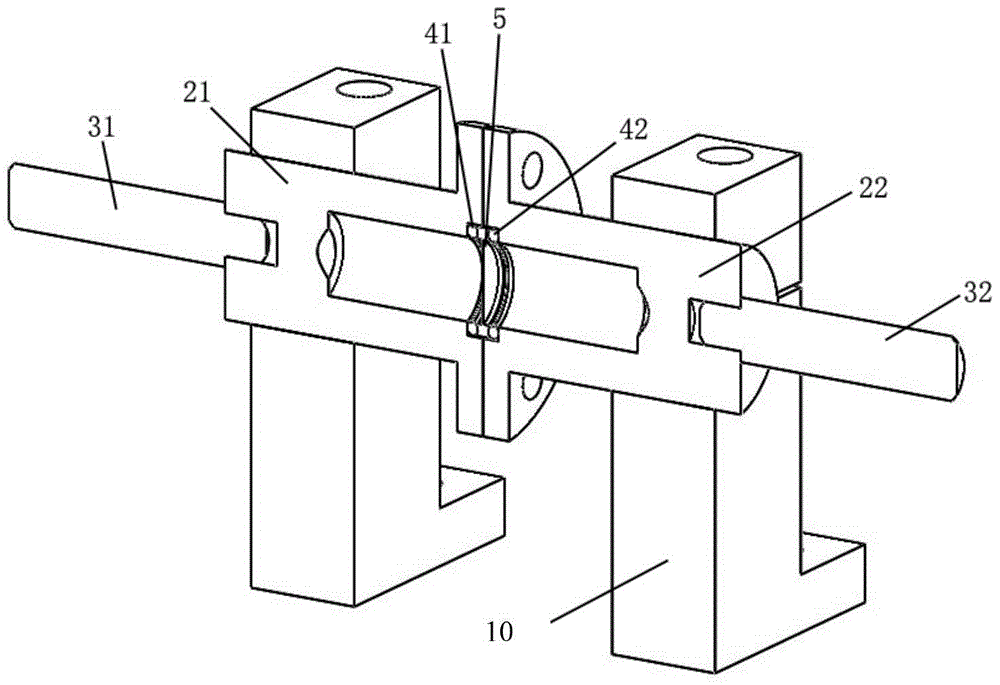

[0033] see Figure 1 to Figure 3 As shown, the interactive pressure testing system of the ultra-thin film of the present embodiment is used to test the fatigue life of the ultra-thin film, and includes two support bodies 10, and the first support bodies 10 connected to each other are respectively arranged on the support body 10. Bellows flange 21 and second bellows flange 22 (also called left bellows flange and right bellows flange), the outer end of the first bellows flange 21 is connected with a first sensor 31, The outer end of the second bellows flange 22 is connected with a second sensor 32 , and an ultra-thin film 5 to be tested is arranged inside between the first bellows flange 21 and the second bellows flange 22 .

[0034] The test device also includes a micro-pressure control unit (not shown in the figure)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com