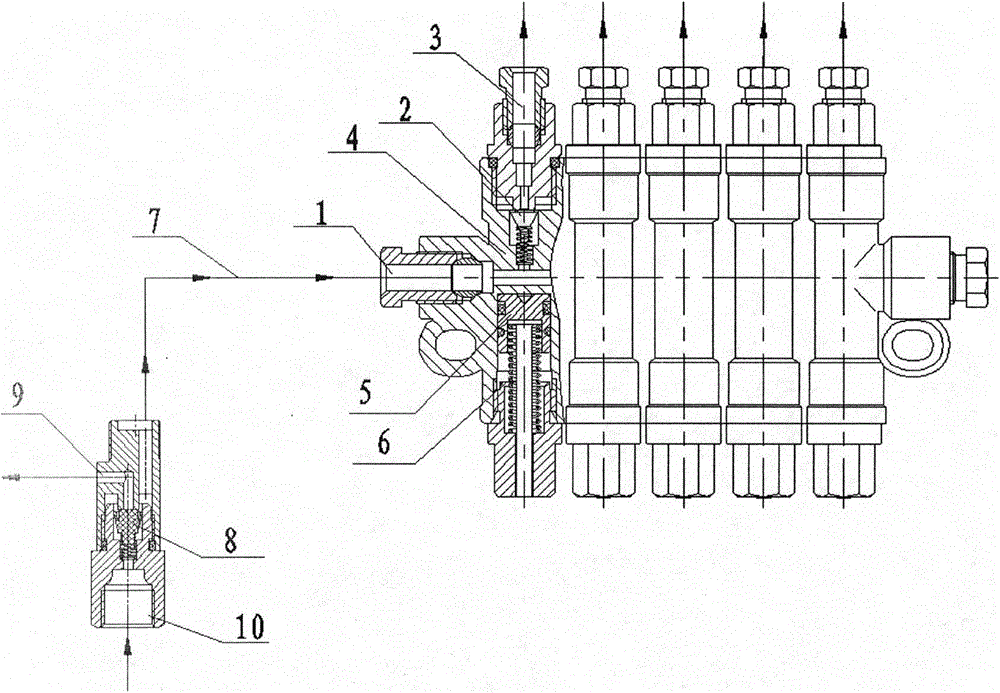

Volumetric distributor with depressurizing function

A distributor and volumetric technology, applied in the field of volumetric distributors, can solve the problems of poor grease fluidity, slow oil output from the first oil outlet 3, etc., and achieve the effect of rapid oil output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

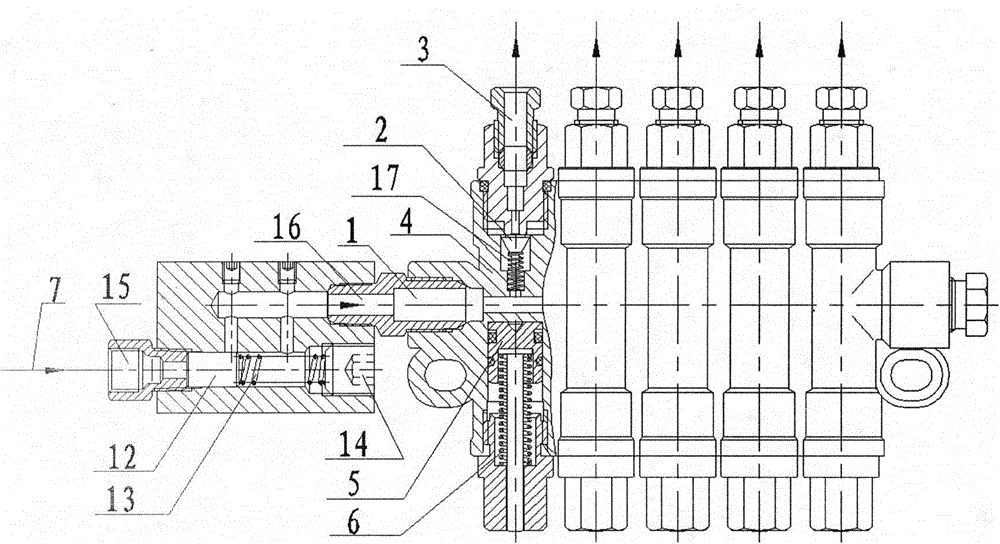

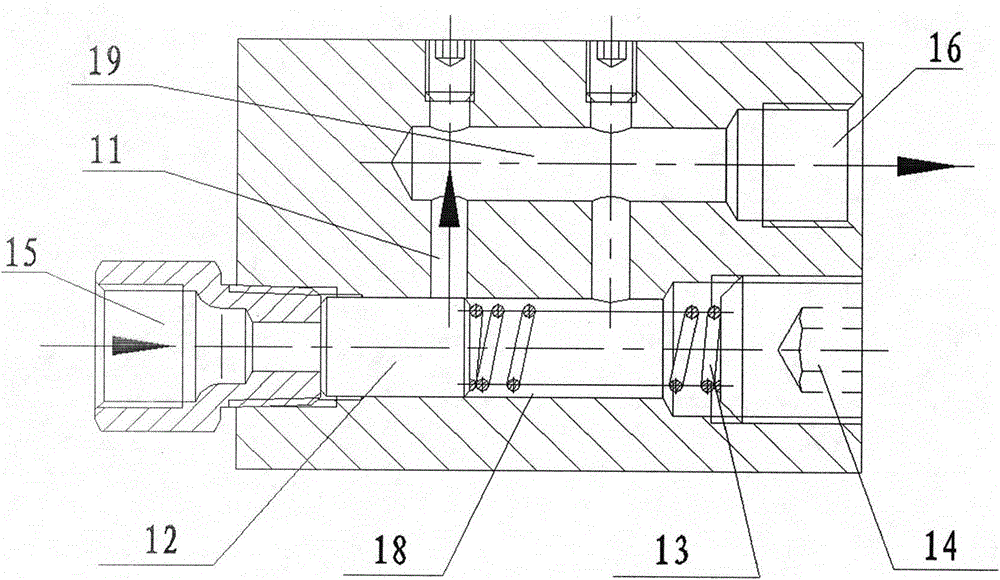

[0029] refer to figure 2 , image 3 , a volumetric distributor with a depressurization function, including a distributor body, a grease delivery pipeline 7, a first oil inlet 1 and a first oil outlet 3, the volumetric distributor also includes a plunger type decompression pressure mechanism, the plunger-type decompression mechanism includes an oil inlet chamber 18 and an oil outlet chamber 19, the oil inlet chamber 18 is sequentially provided with a second oil inlet 15, and a decompression plunger that is slidably matched with the oil inlet chamber 12. A plunger spring 13 and a plug head 14; one end of the oil outlet chamber 19 is provided with a second oil outlet 16, and the other end is closed; a communication pipe 11 is provided between the oil inlet chamber 18 and the oil outlet chamber 19; The second oil outlet 16 is in communication with the first oil inlet 1, and the second oil inlet 15 is in communication with the grease delivery pipeline 7.

[0030] The position be...

Embodiment 2

[0037] refer to figure 2 , image 3 , a volumetric distributor with a depressurization function, including a distributor body, a grease delivery pipeline 7, a first oil inlet 1 and a first oil outlet 3, the volumetric distributor also includes a plunger type decompression pressure mechanism, the plunger-type decompression mechanism includes an oil inlet chamber 18 and an oil outlet chamber 19, the oil inlet chamber 18 is sequentially provided with a second oil inlet 15, and a decompression plunger that is slidably matched with the oil inlet chamber 12. A plunger spring 13 and a plug head 14; one end of the oil outlet chamber 19 is provided with a second oil outlet 16, and the other end is closed; a communication pipe 11 is provided between the oil inlet chamber 18 and the oil outlet chamber 19; The position between the decompression plunger and the communication pipeline should satisfy: when the plunger spring 13 is in a compressed state, the second oil inlet 15 communicates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com