gas stove

A gas stove and burner technology, which is used in heating fuels, household appliances, household stoves/stoves, etc., can solve the problems of too small gas volume and burner fire, etc., to prevent fire, reduce over-regulation, and improve The effect of thermostatic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

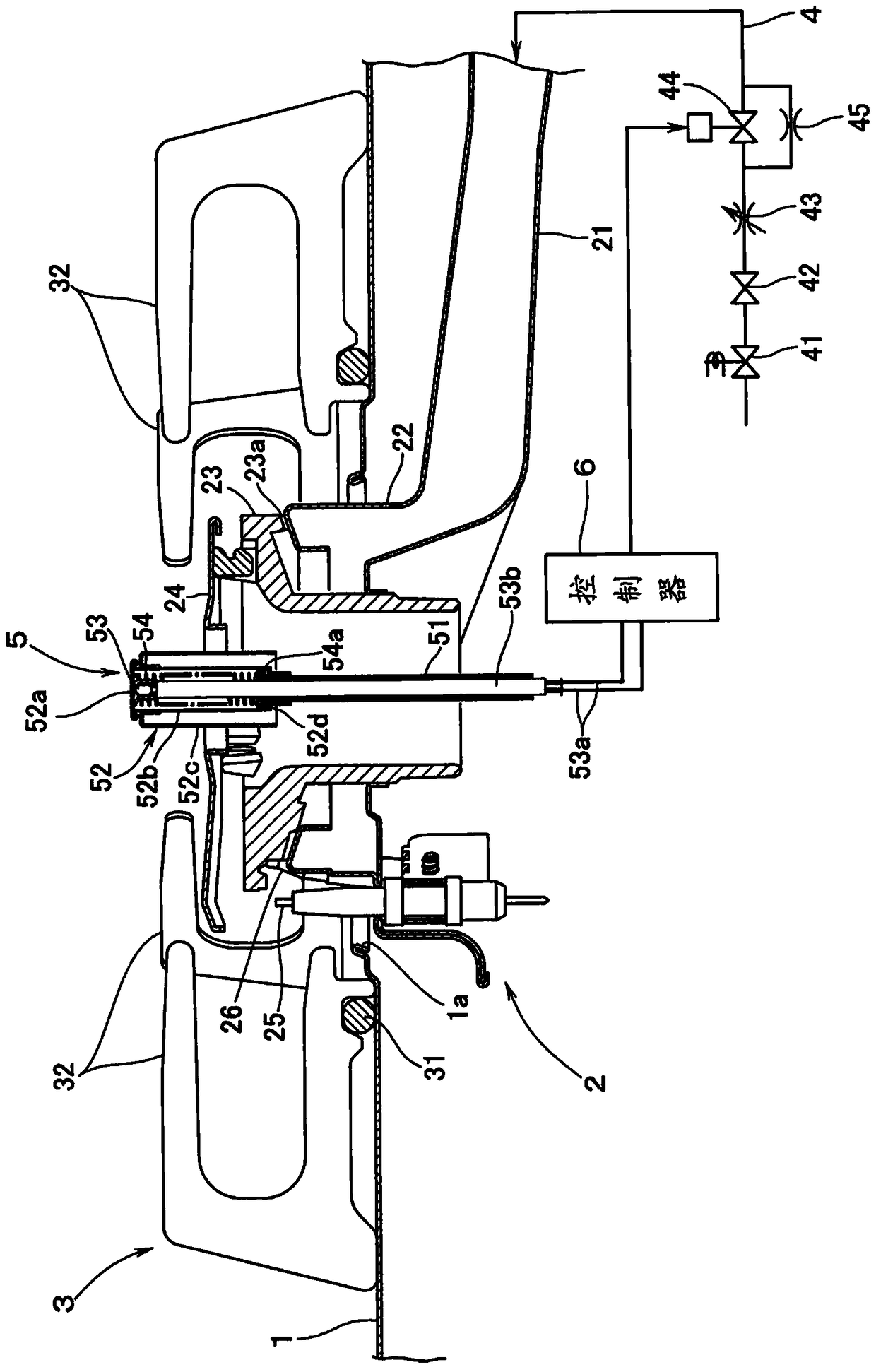

[0021] refer to figure 1 , 1 is a top plate which covers the upper surface of the oven main body which is not shown in figure. The burner opening 1a is provided in the top plate 1, and the burner 2 is provided in the stove main body so that it may face the burner opening 1a. On the top plate 1, a fire prop 3 is arranged to surround the burner 2, and the fire prop 3 is formed by radially installing a plurality of fire prop claws 32 on the ring-shaped fire prop frame 31, and is placed on the Cooking containers such as pots on the fire support 3 are heated by the burner 2 .

[0022] The burner 2 consists of a known annular burner having an annular burner body 22 connected to a mixing tube 21, placed on the burner body 22 and formed between it and the burner body 22 The annular burner cover 23 of the flame outlet 23 a, the annular secondary air guide plate 24 placed on the burner cover 23 and forming a secondary air passage between it and the burner cover 23 . In addition, an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com