Hollow anode for plasma thruster of cusped magnetic field

A hollow anode and plasma technology, applied in the direction of using plasma, thrust reverser, machine/engine, etc., can solve the problems of demagnetization of permanent magnets and shortening of thruster life, and achieve the improvement of life, efficiency and prolong life of anode. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

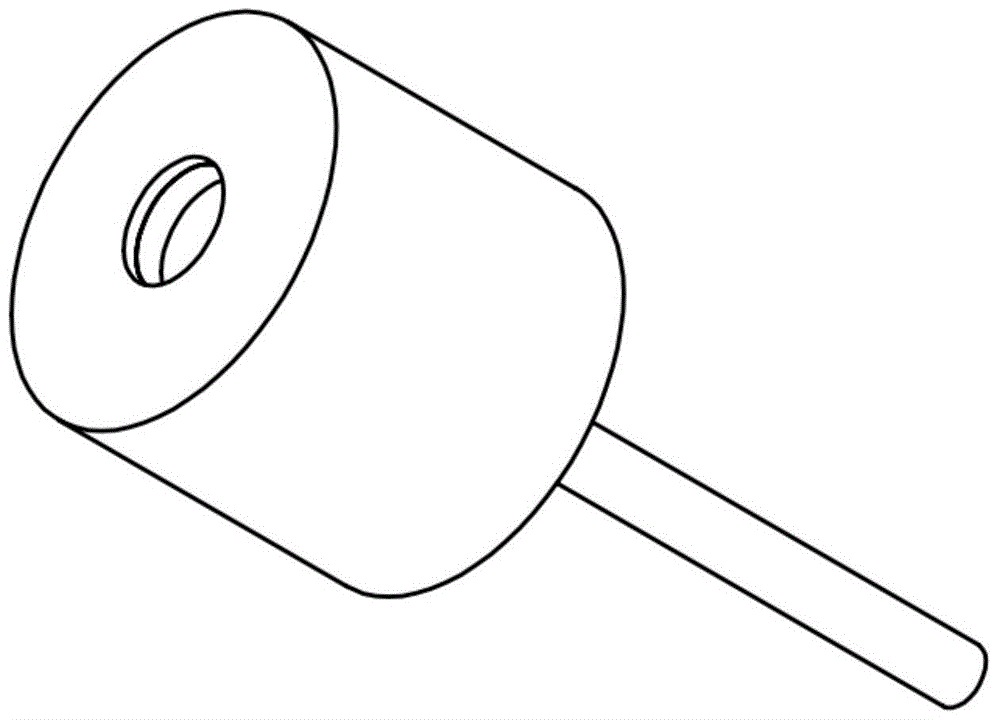

[0029] Embodiment 1: A hollow anode for a tangent magnetic field plasma thruster according to this embodiment is characterized in that it includes three parts: a gas distributor 1, a buffer chamber 2 and a ceramic sleeve 3;

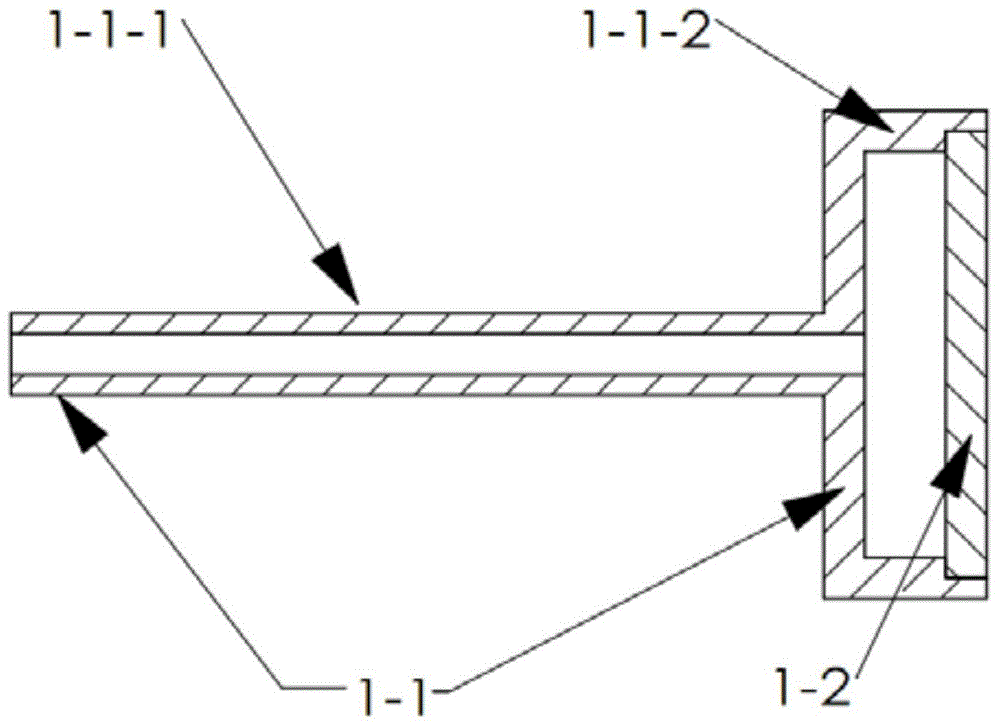

[0030] The gas distributor 1 includes an air supply part 1-1 and a distributor bottom plate 1-2;

[0031] The air supply part 1-1 includes two parts: a conduit 1-1-1 and a chamber 1-1-2, one side of the chamber 1-1-2 communicates with the conduit 1-1-1, and the cavity The other side of the chamber 1-1-2 communicates with the bottom surface of the buffer chamber 2. The center of the other bottom surface of the buffer chamber 2 has a hole and leads to the inside of the discharge channel. The distributor bottom plate 1-2 is connected to the chamber 1-1 The boss of -2 realizes the transition fit;

[0032] Figure 6 As shown, the ceramic sleeve 3 completely surrounds the chamber 1-1-2 and the buffer chamber 2, so that electrons can only enter the inside of t...

specific Embodiment approach 2

[0048] Embodiment 2: This embodiment differs from Embodiment 1 in that: the gas distributor 1 is a gas distributor made of metal. In practice, stainless steel is used to withstand a certain pressure difference.

[0049] Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0050] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the buffer cavity 2 is made of pure iron.

[0051] Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com