High-temperature platinum resistor well logging device

A platinum resistance and logging technology, applied in construction and other fields, can solve the problems of not working properly, poor linearity, and inability to obtain temperature measurement values, etc., and achieve the effect of wide temperature range and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0009] Specific implementation manners: the present invention is not limited by the following examples, and specific implementation manners can be determined according to the technical solutions of the present invention and actual conditions.

Embodiment

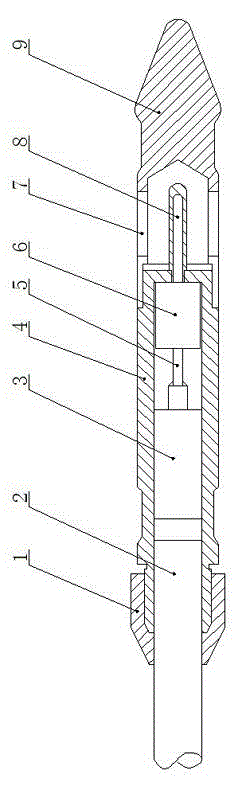

[0010] Example: such as figure 1 As shown, the high-temperature platinum resistance logging device includes an insulation cylinder 4, the upper port of the insulation cylinder 4 is covered with a compression nut 1, and the lower end surface is provided with a probe cover extending downward, which is placed in the insulation cylinder 4 and connected sequentially. The temperature transmitter 3, the temperature sensor 5 and the probe fixing piece 6, the probe 8 is fixedly connected with the probe fixing piece 6, and the probe 8 extends into the probe cover. The temperature transmitter 3 is connected to the coaxial cable 2, and the coaxial cable 2 protrudes from the compression nut 1, and is connected with the surface SPT1 type portable numerical control logging surface system. Screw the guide cone 9 at the bottom of the insulation tube 4 .

[0011] Described insulation cylinder 4 is made of steel, and its inner wall is provided with heat-resistant layer, and heat-resistant layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com