Method for recycling DCPC (deacetyl cephalosporin C) from cephalosporin C resin adsorption waste liquor

A technology of resin adsorption and spore bacteria, applied in the field of chemical pharmaceuticals, can solve the problems of polluted environment, poor product quality, low adsorption capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1) Ion exchange resin desalination: the cephalosporin C resin adsorption raffinate (pH2.8, DC content 423ug / ml) is passed through 100ml of LXT-200 resin (gel-type strong base) from top to bottom at a flow rate of 2BV / h Anion exchange resin, produced by Xi’an Lanxiao Technology New Materials Co., Ltd.), the effluent was detected with 1% (w / w) barium chloride solution, and when a small amount of white precipitate was produced, the resin adsorption was stopped, and the effluent was collected as desalination liquid.

[0048] 2) Resin adsorption and desorption: pass the obtained desalination solution (pH3.1, DC content 410ug / ml) through 100ml LXT-081 (styrene-divinylbenzene macroporous adsorption) at a flow rate of 1BV / h from top to bottom Resin, produced by Xi'an Lanxiao Science and Technology New Material Co., Ltd.), the DCPC titer in the resin column effluent was detected by liquid chromatography, and the resin adsorption was stopped when the effluent titer was 4ug / ml. T...

Embodiment 2- Embodiment 6

[0052] In order to further illustrate the embodiment, each process factor of the present invention is examined separately.

[0053] Adjust the pH of the cephalosporin C resin adsorption raffinate to 2.5, 2.8, 3.2, 3.5, 4.0 respectively, and pass through 5 parts of 100ml LXT-203 resin (macroporous weak base anion exchange Resin, produced by Xi'an Lanxiao Technology New Material Co., Ltd.), the effluent is detected with 1% barium chloride solution, and if white precipitation occurs, it shows that there is sulfate radical leakage, and the adsorption is stopped. Investigate the processing capacity of the resin under different pH conditions (after the anion exchange resin fails, the pH will gradually decrease).

[0054] Example

Embodiment 7- Embodiment 11

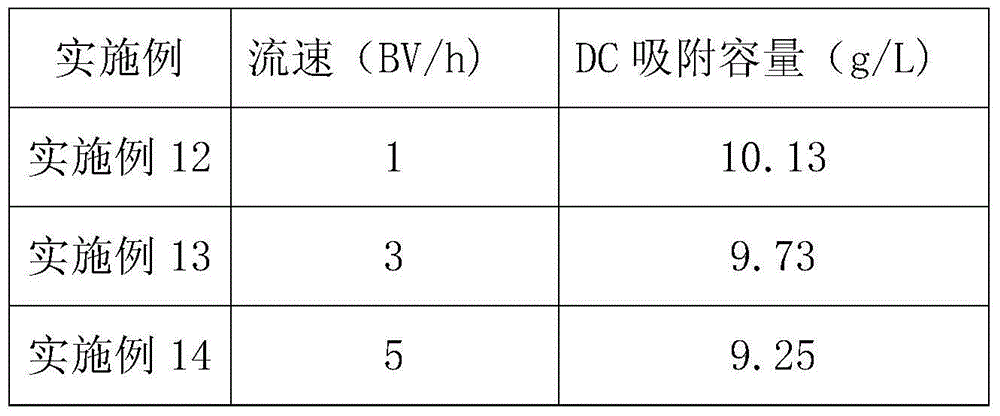

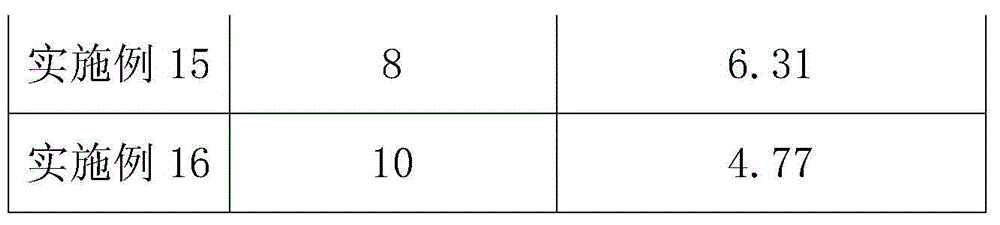

[0056] Ion exchange resins perform desalting at different flow rates:

[0057] Example

[0058] Adjust the pH of the cephalosporin C resin adsorption raffinate to 2.73, and the DC content to 531ug / ml, and pass through 5 each Part 100ml of LXT-207 resin (gel strong base anion exchange resin, produced by Xi'an Lanxiao Technology New Materials Co., Ltd.), the effluent is detected with 1% (w / w) barium chloride solution. If white precipitation occurs, then It shows that there is leakage of sulfate radical, stop the adsorption. Investigate the processing capacity of the resin under different pH conditions (after the anion exchange resin fails, the pH will gradually decrease)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com