Grounding wire winding device

A grounding wire and winding technology, which is applied in the field of grounding wire winding devices, can solve the problems of low operating efficiency, heavy workload of operating personnel, and affecting power supply of the power system, so as to reduce personnel investment, shorten winding time, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

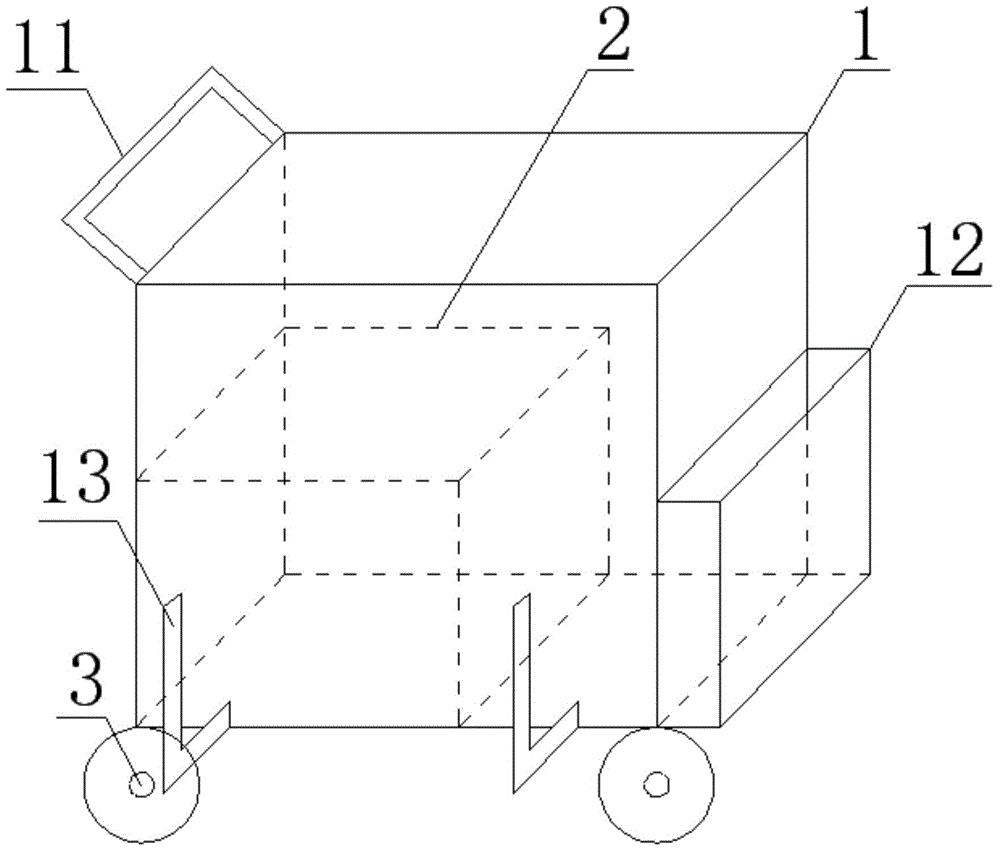

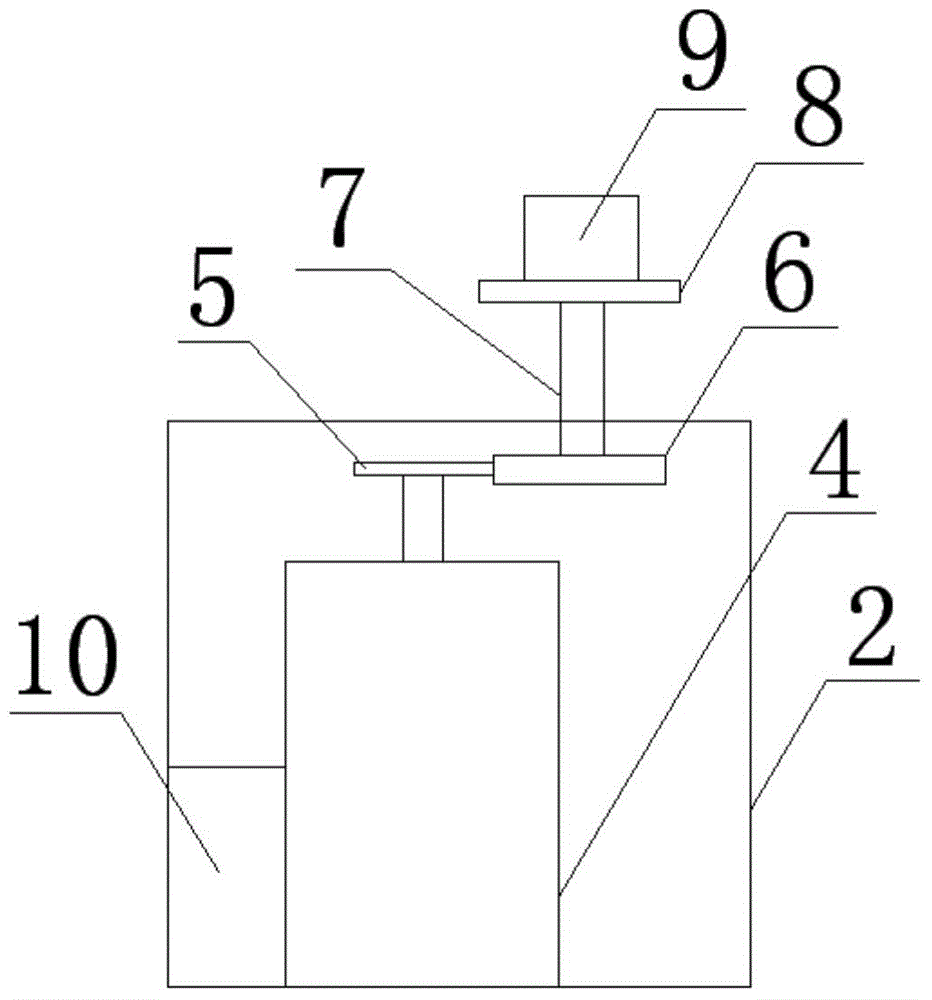

[0019] The grounding wire winding device of the present invention includes a housing 1, a winding device 2 and a wheel 3, the winding device 2 is arranged in the housing 1, and the wheels 3 are arranged at four corners at the bottom of the housing 1; The winding device 2 includes a motor 4, a first gear 5, a second gear 6, a transmission rod 7, a turntable 8, a fixed box 9 and a power junction box 10, the output shaft of the motor 4 is fixedly connected to the first gear 5, the first The gear teeth of the gear 5 and the gear teeth of the second gear 6 mesh with each other, and the center of the second gear 6 is fixedly connected to one end of the transmission rod 7, and the other end of the transmission rod 7 is fixedly connected to the bottom end of the turntable 8, and the top end of the turntable 8 is fixed Connected with a fixed box 9; one side of the motor 4 is provided with a power junction box 10, the power line of the motor 4 is connected to one end of the connection te...

Embodiment 2

[0025] The grounding wire winding device of the present invention includes a housing 1, a winding device 2 and a wheel 3, the winding device 2 is arranged in the housing 1, and the wheels 3 are arranged at four corners at the bottom of the housing 1; The winding device 2 includes a motor 4, a first gear 5, a second gear 6, a transmission rod 7, a turntable 8, a fixed box 9 and a power junction box 10, the output shaft of the motor 4 is fixedly connected to the first gear 5, the first The gear teeth of the gear 5 and the gear teeth of the second gear 6 mesh with each other, and the center of the second gear 6 is fixedly connected to one end of the transmission rod 7, and the other end of the transmission rod 7 is fixedly connected to the bottom end of the turntable 8, and the top end of the turntable 8 is fixed Connected with a fixed box 9; one side of the motor 4 is provided with a power junction box 10, the power line of the motor 4 is connected to one end of the connection te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com