LL type oil seal puller

A technology for external pullers and oil seals, which is applied in metal processing, metal processing equipment, hand-held tools, etc., can solve the problems of heavy workload and low oil seal efficiency, and achieve the goals of improving applicability, improving work efficiency, and shortening working hours Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

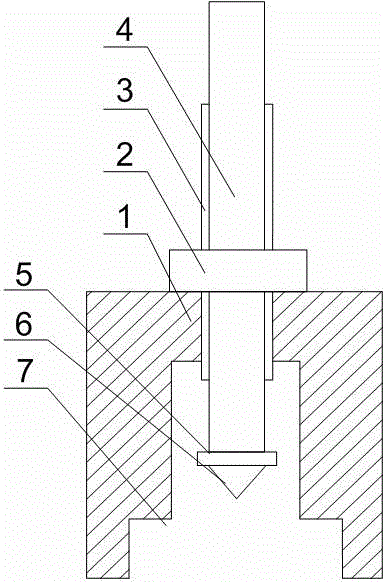

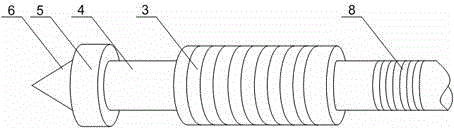

[0020] Such as figure 1 with figure 2 As shown, this embodiment includes a support base 1 with a U-shaped groove at the bottom, a through hole is opened at the upper end of the support base 1, and a pull-out rod 4 passes through the through hole and is placed in the U-shaped groove. A hollow and ring-shaped connecting block 3 is sleeved in the middle of the spool. The connecting block 3 is threaded with the through hole. An external thread 8 is also provided on the outer wall of the pull rod 4, and the external thread 8 is connected to the connecting block. The upper section of the inner wall of 3 is threaded, and the end of the pull-out rod 4 is equipped with a clamping disc 5, the outer diameter of the clamping disc 5 is greater than the outer diameter of the pull-out rod 4; also includes a nut 2, the nut 2 and The connection block 3 is threaded.

[0021] When working, manually cut the relief groove temporarily sealed on the side wall of the oil seal, then place the U-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com