A manufacturing method of a ring beam structural member in a hydraulic plug-type platform lifting system

A technology of platform lifting and manufacturing method, which is applied to manufacturing tools, welding equipment, metal processing, etc., can solve the problem that the concentricity and flatness of the pin seat and the cylinder pin seat cannot be guaranteed, such as the opening size of the ring beam structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

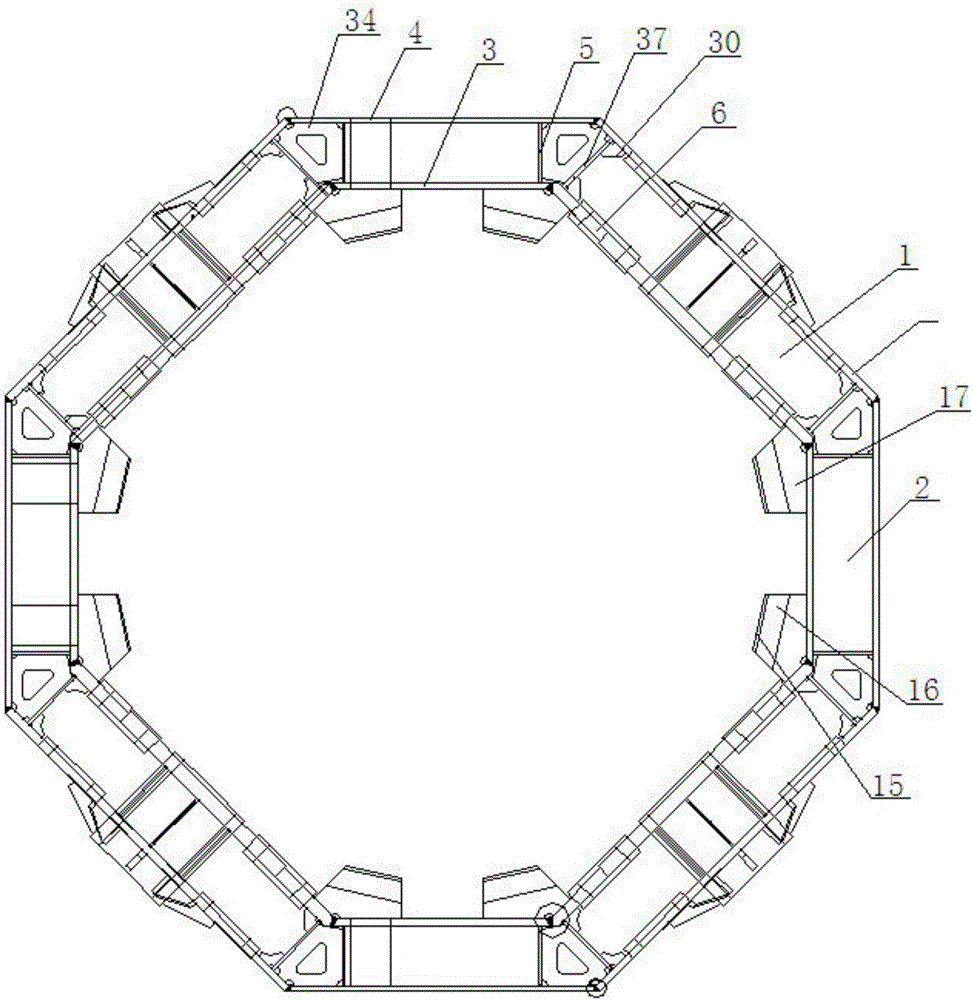

[0052] see Figure 1 to Figure 2 , a hydraulic pin-type platform lifting system, including a pile fixing frame, a balance assembly, a ring beam structure and a lifting cylinder, wherein the ring beam structure is an important force-bearing and force-transmitting component of the lifting system. The ring beam structure includes a fixed ring beam and a moving ring beam, and the moving ring beam and the fixed ring beam are arranged correspondingly; the fixed ring beam and the moving ring beam both include a guide plate 15 and a connecting plate welded as one in sequence 16. The support plate 17 and the ring beam assembly, the ring beam assembly is formed by connecting a plurality of main beams 1 and connecting beams 2 at intervals. The connecting beam 2 includes an inner plate 3 and an outer plate 4 arranged in parallel and spaced apart...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com