Welding method capable of eliminating hook defects of magnesium alloy friction stirring overlap joint

A technology for hook-shaped defects and lap joints, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve problems such as difficulty in ensuring joint quality, achieve simple process assembly and welding processes, broad industrial application prospects, and improve The effect of joint performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

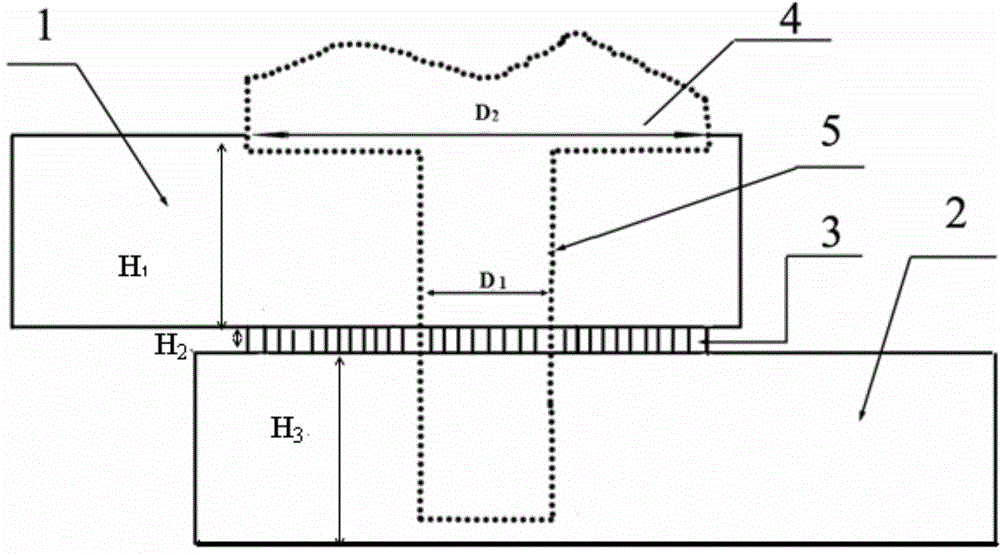

Method used

Image

Examples

Embodiment 1

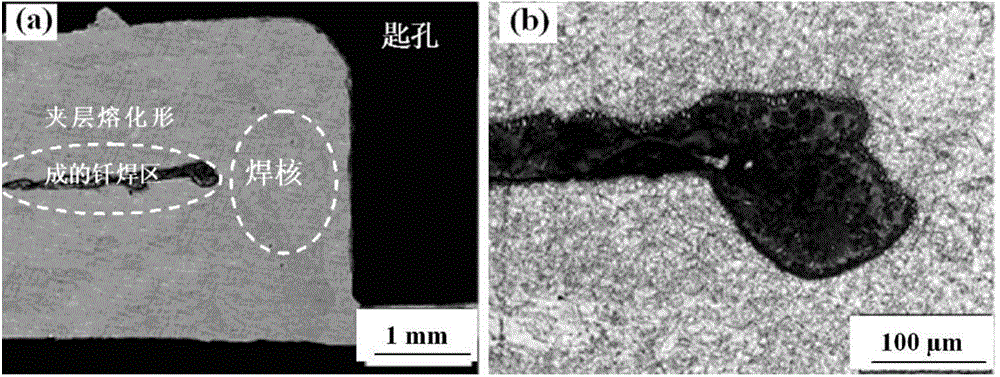

[0030] The 2.4mm thick magnesium alloy plate is lapped and assembled, a 0.1mm thick tin interlayer is preset between the upper and lower plates, and then conventional friction stir spot welding (needle diameter 3mm, shaft shoulder 10mm, needle length 1.8mm, speed 3000r / min, dwell time 5s). Microstructural analysis and mechanical performance tests showed that there were no hook defects in the joints (such as figure 2 As shown), it is replaced by the Sn-Mg alloy zone formed by the interaction of tin and magnesium alloy, and the tensile load of the spot welded joint is about 3.0kN.

Embodiment 2

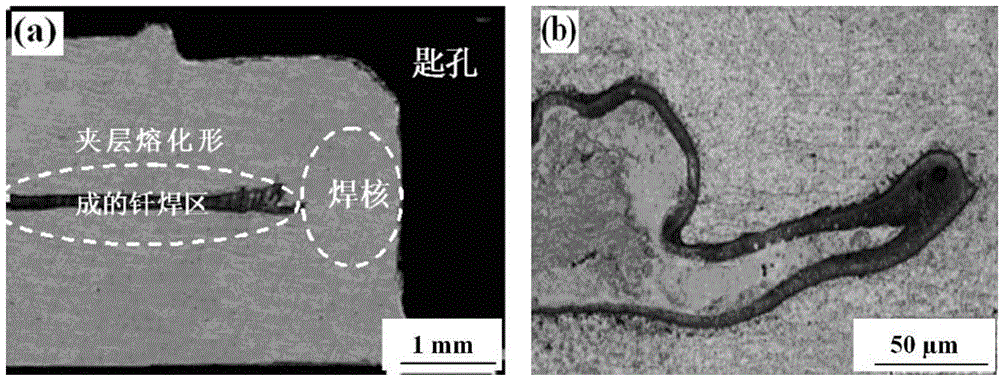

[0032] The 2.4mm thick magnesium alloy plate is lapped and assembled, and a 0.2mm thick zinc interlayer is preset between the upper and lower plates for conventional friction stir spot welding (needle diameter 3mm, shaft shoulder 10mm, needle length 1.8mm, speed 3000r / min , dwell time 5s). Microstructural analysis revealed no hook defects in the joint (eg image 3shown), replaced by the Zn-Mg alloy zone formed by the diffusion reaction of zinc and magnesium alloy. The mechanical performance test shows that the tensile load of the spot welded joint is about 4.0kN.

Embodiment 3

[0034] The 2.4mm thick magnesium alloy plates are lapped and assembled, and a 0.1mm thick zinc-tin alloy (5wt% zinc content, the rest is tin) interlayer is coated between the upper and lower plates, and conventional friction stir spot welding (needle diameter 3mm, Shaft shoulder 10mm, needle length 1.8mm, speed 3000r / min, dwell time 5s). Microstructural analysis revealed no hook defects in the joint (eg Figure 4 shown), replaced by the Zn-Sn-Mg ternary alloy region formed by the diffusion reaction of zinc-tin alloy and magnesium alloy. The mechanical performance test shows that the tensile load of the spot welded joint is about 3.4kN.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com