Low voltage point welding machine

A spot welding machine, low-voltage technology, applied in welding power sources, welding equipment, resistance welding equipment and other directions, can solve the problems of inconvenient operation, poor safety, unfavorable popularization, etc., and achieve a simple structure, few components, and easy mass production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing:

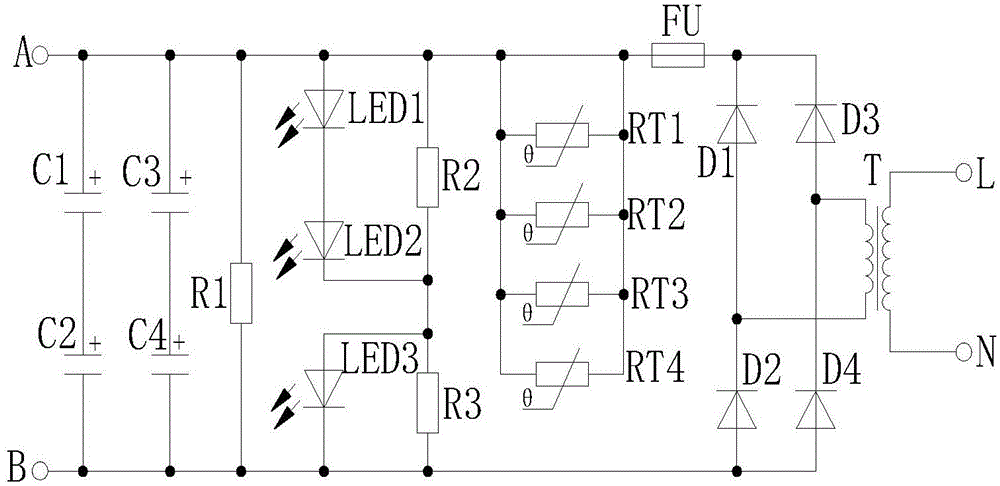

[0010] like figure 1 Shown: the present invention includes the first electrolytic capacitor C1, the second electrolytic capacitor C2, the third electrolytic capacitor C3, the fourth electrolytic capacitor C4, the first resistor R1, the second resistor R2, the third resistor R3, the first light emitting diode LED1 , the second light-emitting diode LED2, the third light-emitting diode LED3, the first thermistor RT1, the second thermistor RT2, the third thermistor RT3, the fourth thermistor RT4, the fuse resistor FU, the first diode The tube D1, the second diode D2, the third diode D3, the fourth diode D4 and the transformer T, the anode of the first point solution capacitor C1 are simultaneously connected with the first output terminal of the low-voltage spot welding machine, the third electrolytic The anode of the capacitor C3, the first end of the first resistor R1, the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com