System and method for separating and regenerating paint slag

A technology of regeneration system and separation system, applied in the field of paint slag recycling system, can solve the problems of waste of coating materials, air pollution, large waste paint slag, etc., to avoid secondary pollution, improve work efficiency, and achieve good flocculation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to facilitate the understanding of the present invention, the present invention will be described more fully and in detail below in conjunction with the accompanying drawings and preferred embodiments, but the protection scope of the present invention is not limited to the following specific embodiments.

[0027] Unless otherwise defined, all technical terms used hereinafter have the same meanings as commonly understood by those skilled in the art. The terminology used herein is only for the purpose of describing specific embodiments, and is not intended to limit the protection scope of the present invention.

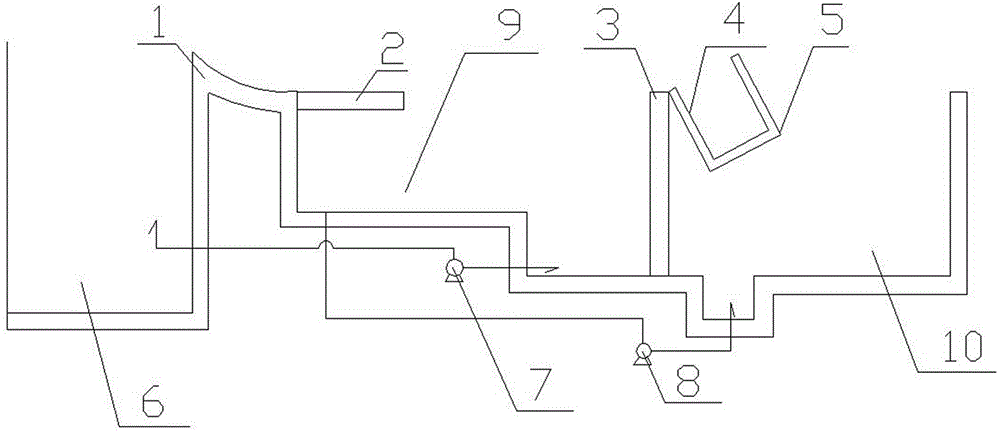

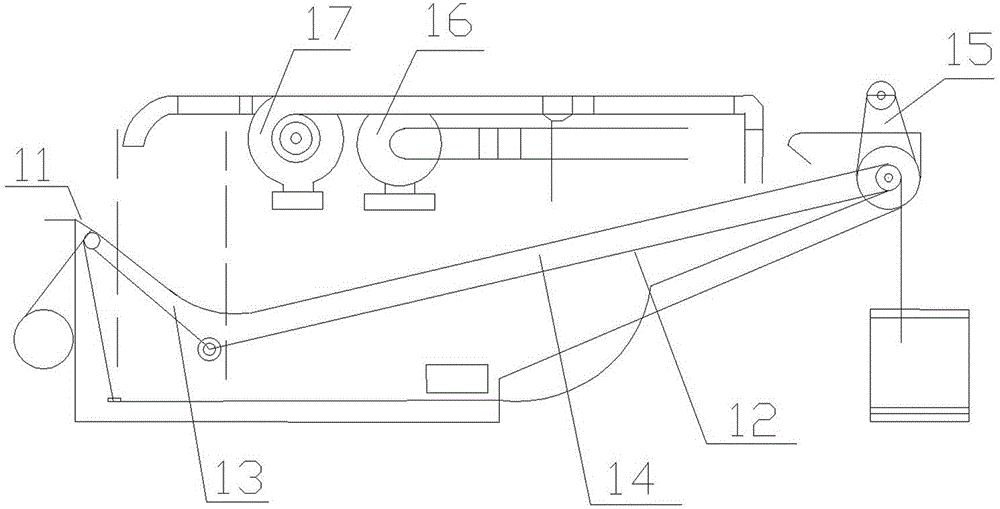

[0028] A paint slag separation and regeneration system of the present invention includes a paint slag separation system and a paint slag regeneration system. The paint slag separation system includes a circulating water tank 6, a scum tank 9, a paint slag collection bucket 5, a slag removal tank 10, a first The circulating pump 7 and the second circulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com