Selective flocculation flotation method for extremely fine ilmenite

A technology of ilmenite and fine particles, which is applied in flotation, solid separation, etc., can solve the problems of unrepresentativeness, increase the process of removing fine minerals, and low content of fine minerals, and achieve the goal of sorting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

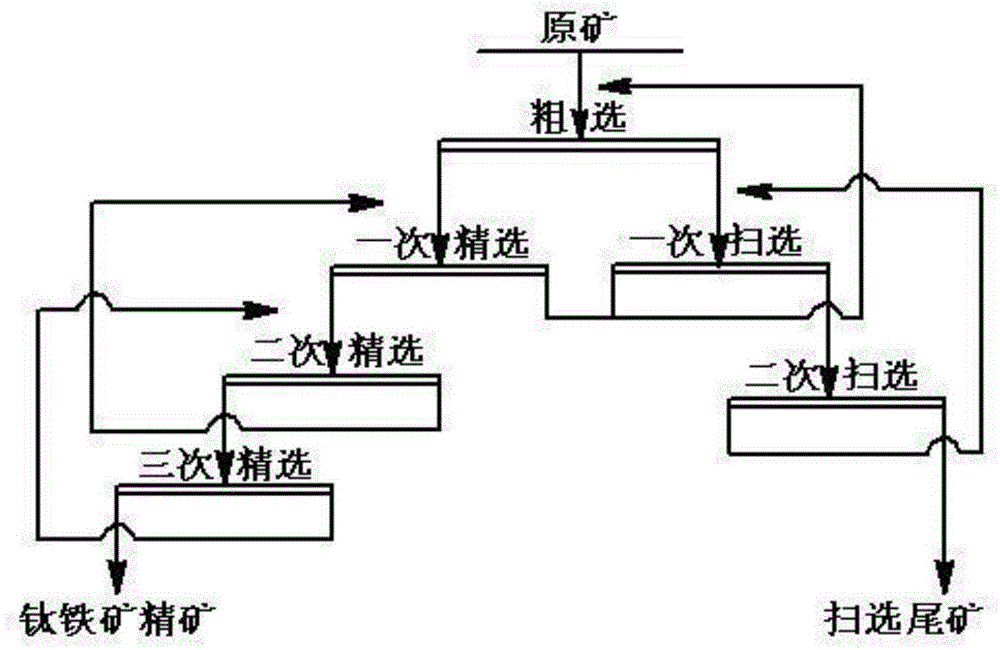

[0027] The raw ore fine-grained ilmenite is the overflow of the secondary inclined plate of the Panzhihua Titanium Concentrator, in which the -28μm particle size content is 70%, and the TiO 2 The grade is 8.89%, and the titanium pyroxene content is about 40%. Wherein, the number of times of flotation column sweeping is two, and the number of times of flotation column selection is three times.

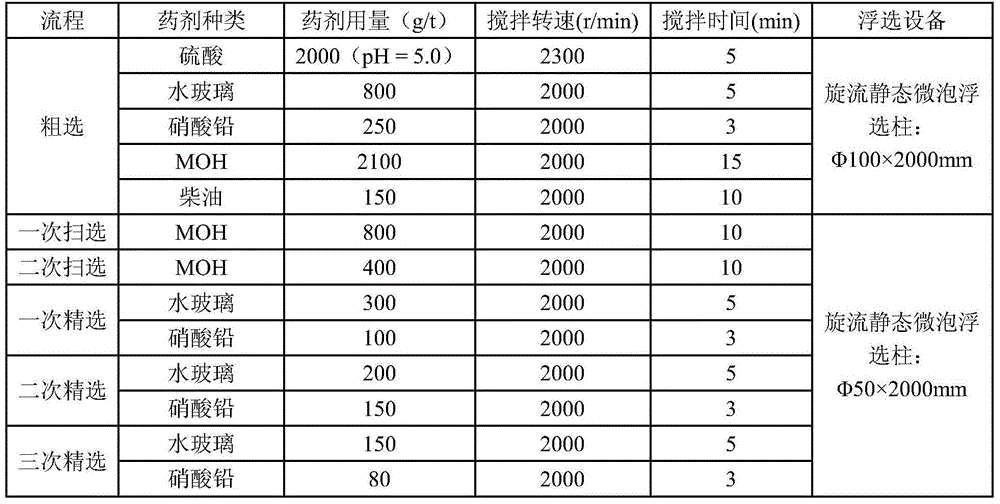

[0028] The reagent system and operating conditions of flotation are shown in Table 1.

[0029]

[0030]Flotation: According to the dosage and operating conditions listed in Table 1, the fine-grained ilmenite in Panzhihua Titanium Separation Plant was flotation, and TiO 2 Titanium concentrate with a grade of 46.62% and a recovery rate of 60.17%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com