An automatic compacting device for solid particle packing

A compacting device, a technology for solid particles, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of high control requirements of displacement and force, damage to packing, and easy jamming of cylinder pistons. Achieve the effect of ensuring safe operation, preventing jumping, and preventing volume change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

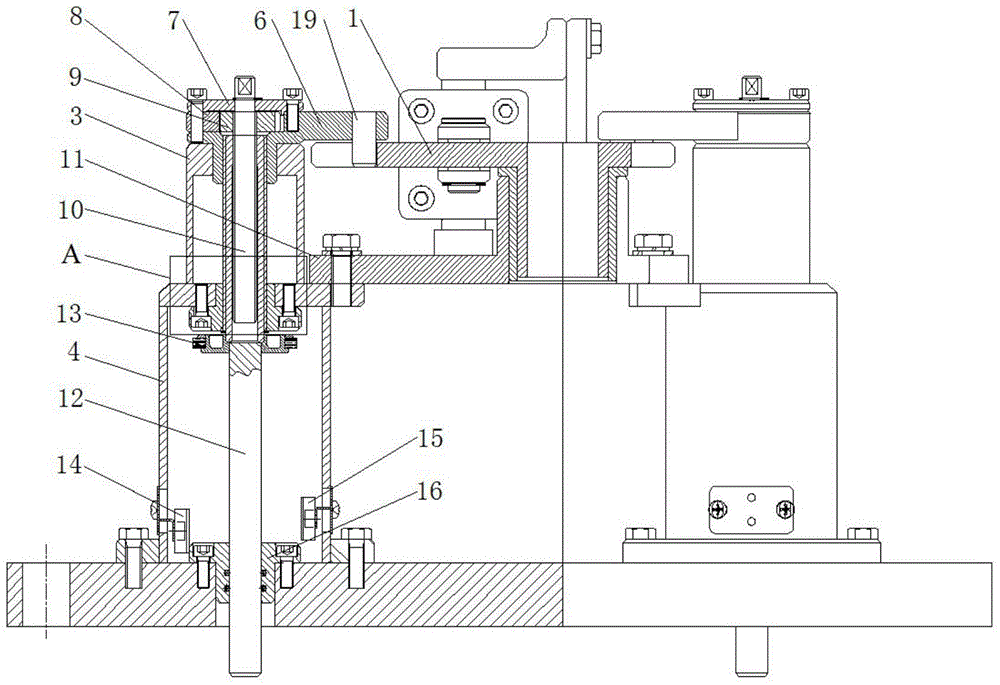

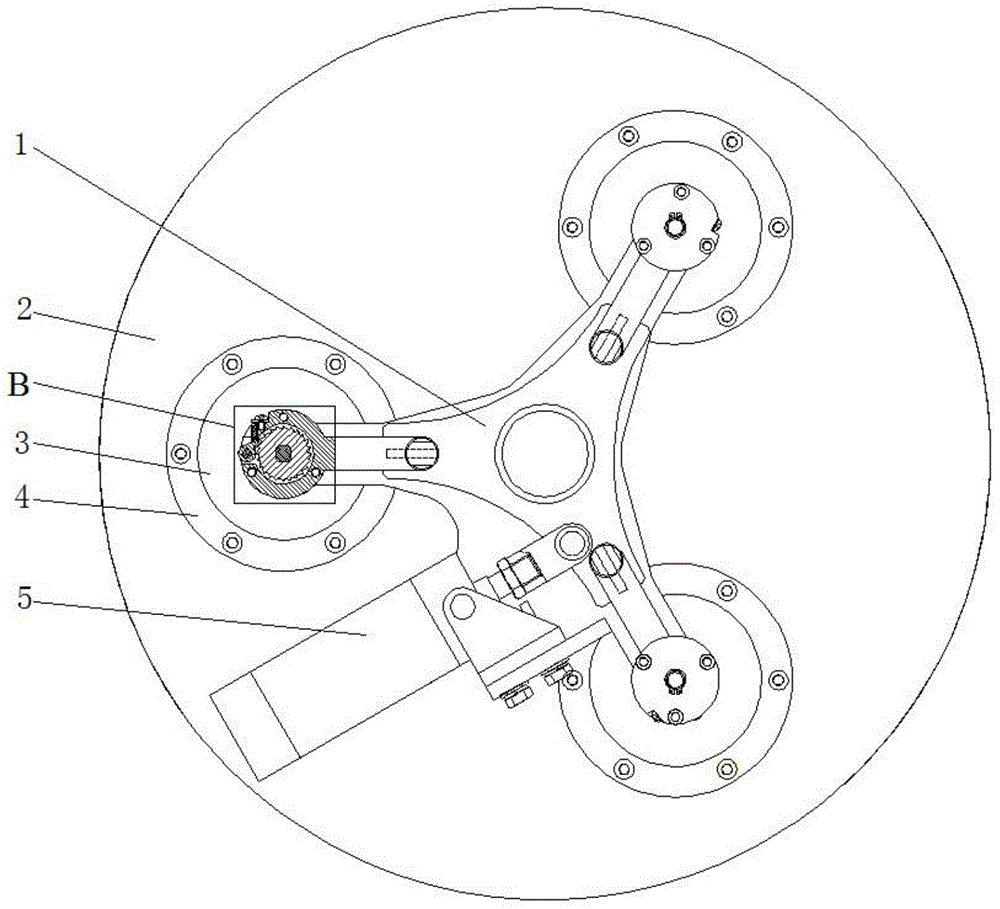

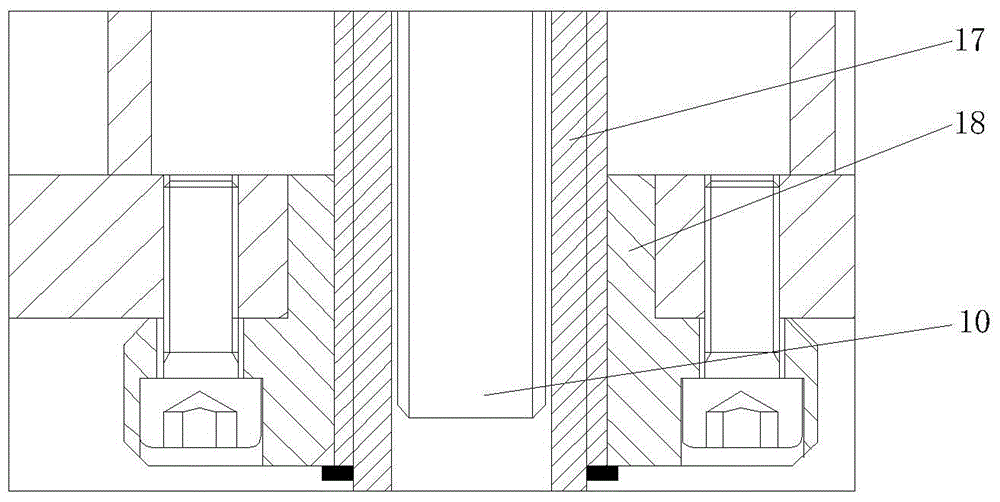

[0022] Such as Figure 1-4 In the shown automatic compacting device for solid particle packing, three cylindrical bases 4 are arranged at intervals along the tower cover 2 of the adsorption tower, and a vertical compacting rod 12 passing through the tower cover 2 is arranged inside the base 4. The lower end of the pressing rod 12 is connected with the packing pressure plate inside the adsorption tower; the top of the base 4 is provided with a cylindrical top seat 3, and the top seat 3 is provided with a driving screw 17, which is configured with a fixed screw sleeve 18; The lower end of transmission screw mandrel 17 links to each other with the upper end of hold-down bar 12, and transmission screw mandrel 17 links to each other with transmission shaft 10, and transmission shaft 10 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com