Semi-solid non-tillage dry direct planting method for multi-cropping type corn

A semi-solid, dry direct seeding technology, applied in botanical equipment and methods, fertilizers made from biological waste, applications, etc., can solve the problem of large water consumption, difficulty in returning the straw of previous crops, low germination rate and seedling emergence rate, etc. It can achieve the effect of serious soil fertility loss, saving straw treatment time, and being beneficial to the seedling stage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

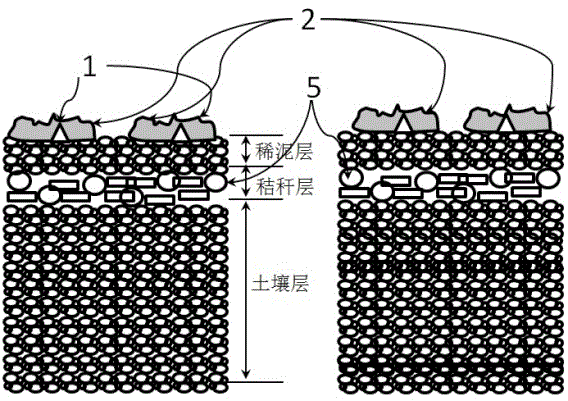

[0040]A semi-solid no-tillage and dry direct seeding method for multi-ripe corn, comprising the following steps:

[0041] 1) Field management before sowing: Before direct seeding, the width of the stubble field is 180-240 cm, the width of the ditch is 10-20 cm, and the depth of the ditch is 15-30 cm. Use a combine harvester for harvesting, use the grass-cutting function of the harvester to evenly chop and spread the crop stalks on the car surface; Spread the straw and use the disc trencher to clear the trench.

[0042] 2) Base fertilizer application before sowing: evenly spread 60% of the total nitrogen fertilizer, 60% of the total potassium fertilizer and 100% phosphate fertilizer on the car surface before clearing the ditch, or spread the same amount of compound fertilizer; the total amount of chemical fertilizer is respectively : Nitrogen fertilizer pure N is 100.0k g / h㎡~150.0kg / h㎡, potassium fertilizer K 2 O is 85.0kg / h㎡~120.0kg / h㎡, phosphate fertilizer P 2 o 5 It is 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com