Motor with two-way type air cooling structure

A technology of air-cooled structure and motor body, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve problems such as restricting component dysfunction and affecting overall performance, and achieve reasonable heat dissipation effect and simple transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with specific embodiments.

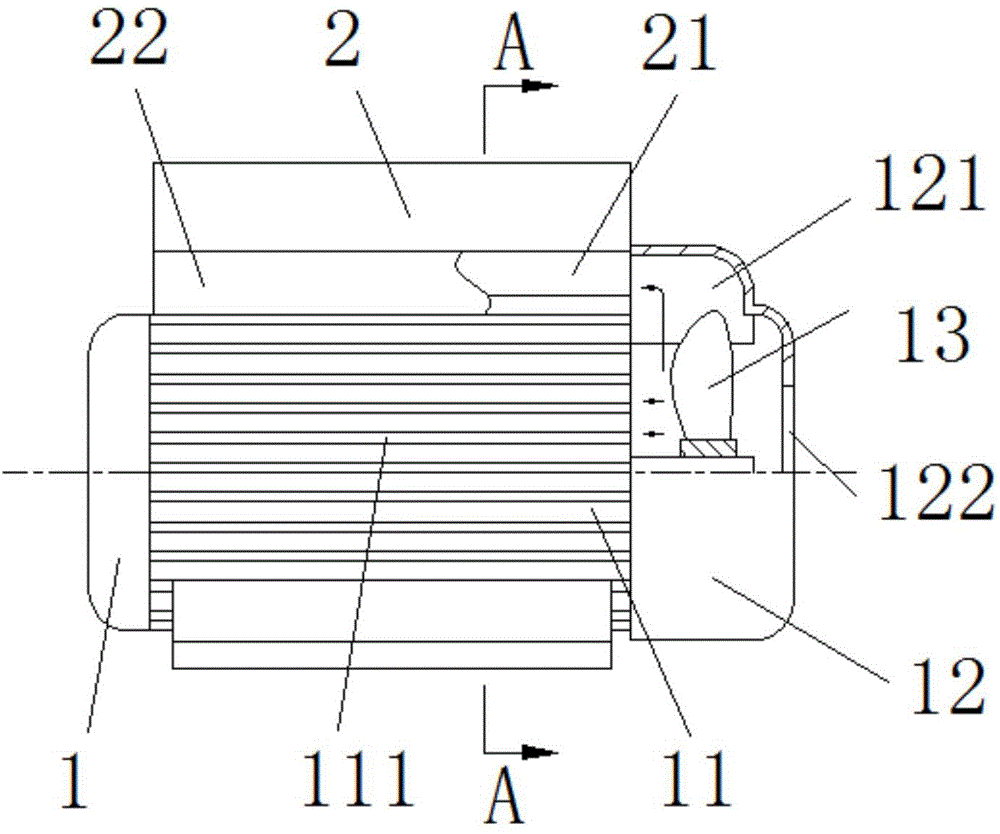

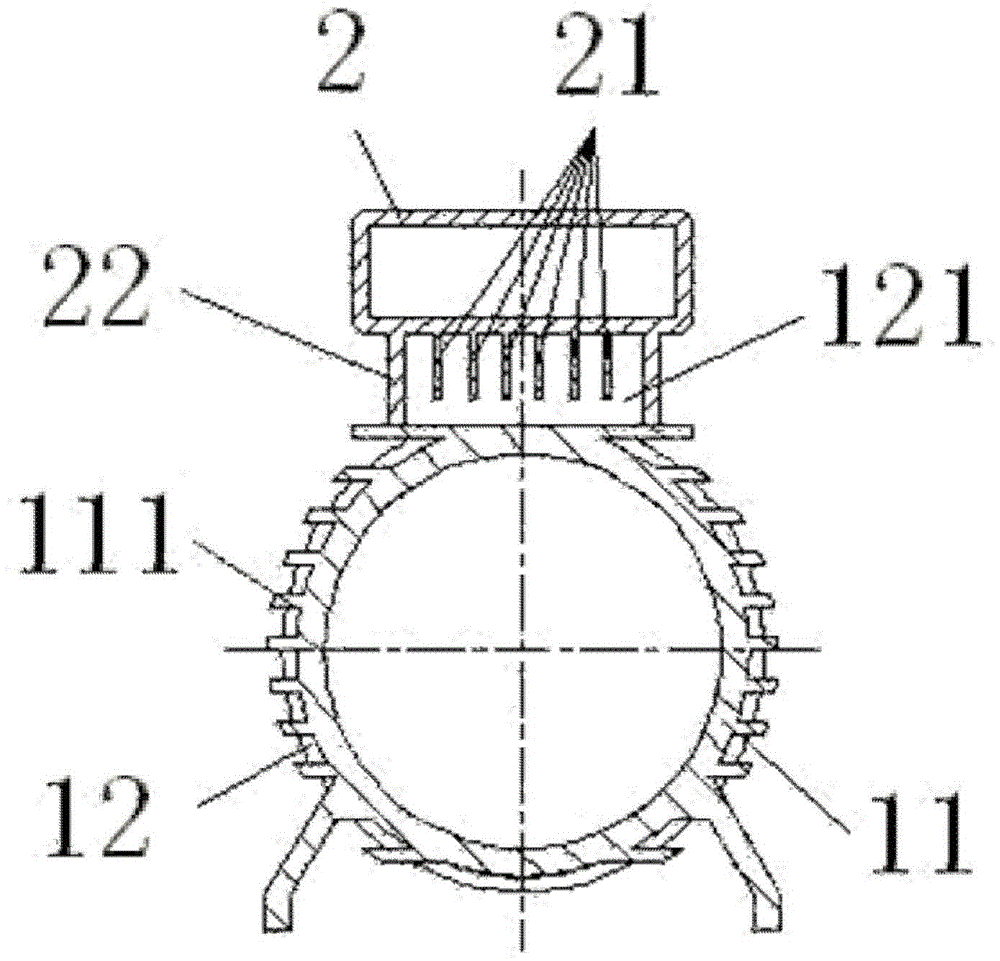

[0020] Such as figure 1 , figure 2 As shown, a motor with a two-way air-cooled structure of the present invention includes a motor body 1 and a control box 2 fixed above the motor body 1. The motor body 1 includes a base 11 and a The casing 12 and the fan 13 located in the casing 12, the outer arc surface of the base 11 is provided with a number of fuselage heat dissipation ribs 111 along its radial direction, and the surface of the drive control box 2 close to the motor body 1 is provided with several parallel ribs. The cooling ribs 21 of the box body, the projection of the cooling ribs 21 along the radial direction of the motor body 1 is located within the outer edge of the casing 12 . The cooling ribs 21 of the box body are located between the motor body 1 and the control box 2 to separate the distance between the two heat sources, so as to prevent heat from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com