On-line monitoring system for gas in transformer oil

A transformer oil and monitoring system technology, applied in the field of electromechanical, can solve the problems of gas generation, low efficiency, incomplete separation of oil and gas separation units, etc., and achieve the effects of high degassing efficiency, speed block, and ensuring detection accuracy and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

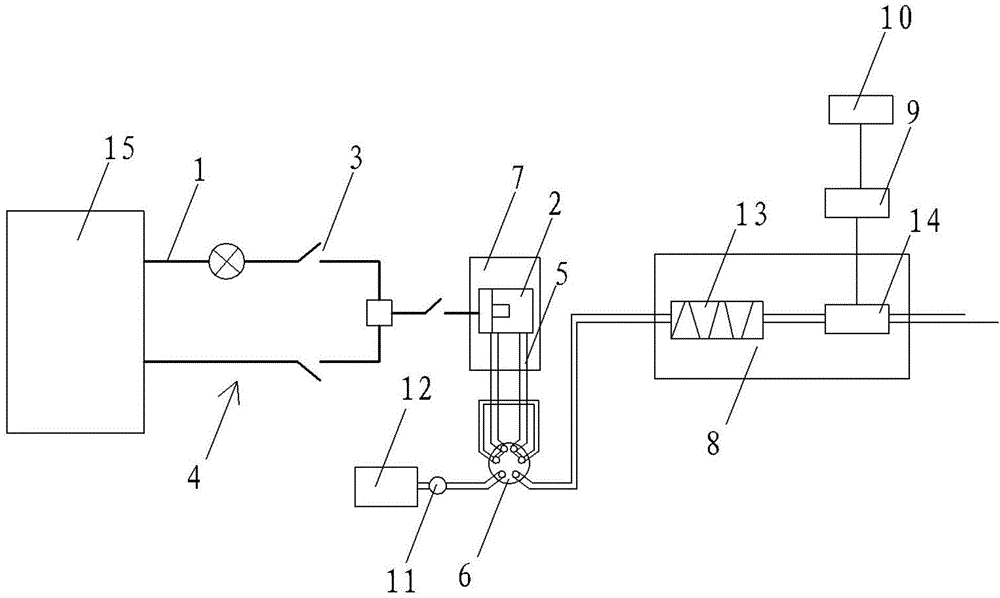

[0019] The online monitoring system for gas in transformer oil includes an input pipe 1 connected to a transformer 15, the input pipe is connected to the cylinder 2 in the oil test degassing unit 7 through a valve 3, and a circuit 4 is connected between the input pipe and the transformer through a valve. The valve is an electromagnetic valve. Several pipes 5 are connected to the cylinder to connect with the sampler 6 , the sampler is connected with the gas separation unit 8 through the connecting pipe, and the gas separation unit is connected with the main control unit 10 through the communication module 9 . The communication module supports optical fiber-based network communication; supports power carrier communication; supports wireless communication. Through various forms of information transmission, it is convenient for the system to receive and avoid being restricted by the environment. Transformer oil is firstly circulated through the circuit, then sampled after the cir...

Embodiment 2

[0024] The online monitoring system for gas in transformer oil includes an input pipe 1 connected to a transformer 15, the input pipe is connected to the cylinder 2 in the oil test degassing unit 7 through a valve 3, and a circuit 4 is connected between the input pipe and the transformer through a valve. The valve is an electromagnetic valve. Two pipelines 5 are connected to the cylinder to connect with the sampler 6 , the sampler is connected with the gas separation unit 8 through the connecting pipe, and the gas separation unit is connected with the main control unit 10 through the communication module 9 . The communication module supports optical fiber-based network communication; supports power carrier communication; supports wireless communication. Through various forms of information transmission, it is convenient for the system to receive and avoid being restricted by the environment. Transformer oil is firstly circulated through the circuit, then sampled after the cir...

Embodiment 3

[0029] The online monitoring system for gas in transformer oil includes an input pipe 1 connected to a transformer 15, the input pipe is connected to the cylinder 2 in the oil test degassing unit 7 through a valve 3, and a circuit 4 is connected between the input pipe and the transformer through a valve. The valve is an electromagnetic valve. Several pipes 5 are connected to the cylinder to connect with the sampler 6 , the sampler is connected with the gas separation unit 8 through the connecting pipe, and the gas separation unit is connected with the main control unit 10 through the communication module 9 . The communication module supports optical fiber-based network communication; supports power carrier communication; supports wireless communication. Through various forms of information transmission, it is convenient for the system to receive and avoid being restricted by the environment. Transformer oil is firstly circulated through the circuit, then sampled after the cir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com