Premixed fuel nozzle for combustor and with drainage structure

A fuel nozzle and combustion chamber technology, applied in the field of gas turbine combustor nozzles and combustor premixed fuel nozzles, can solve problems such as flashback/flame adhesion, increase NOx emissions, and affect air, so as to improve uniform mixing and reduce diameter. Effects of radial velocity, uniform axial velocity distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

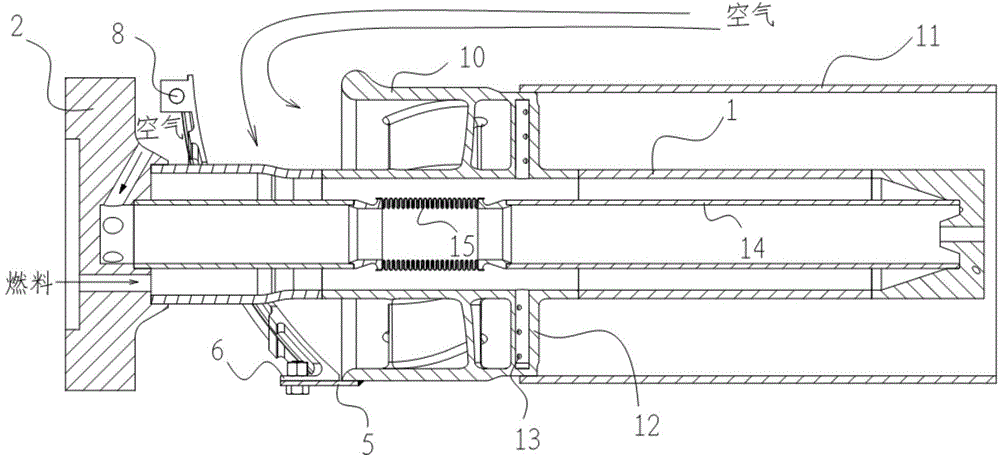

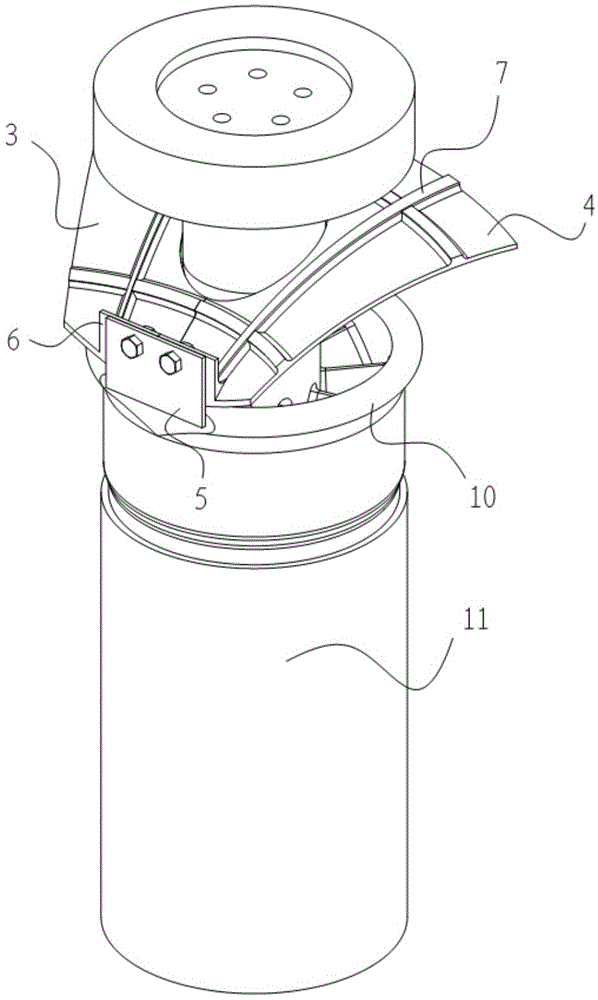

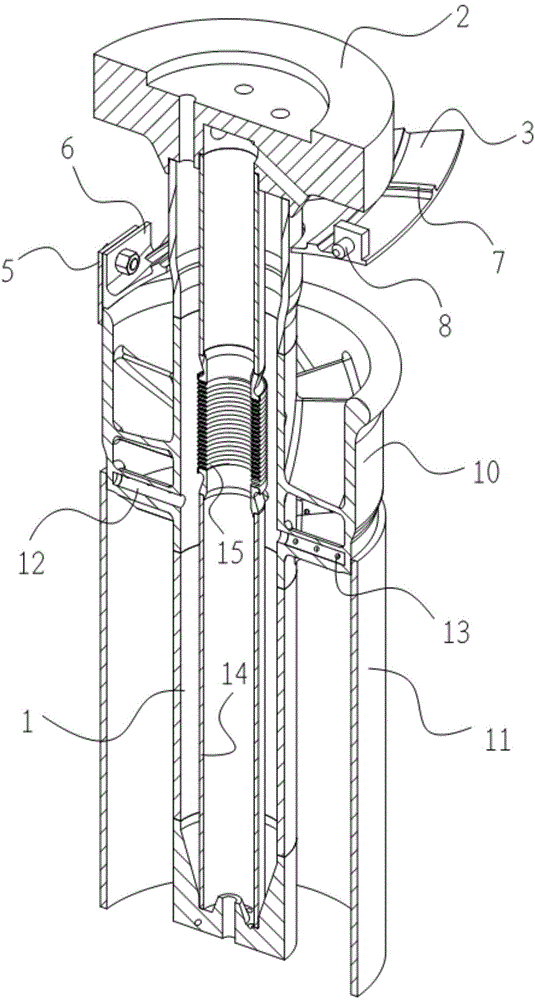

[0018] Such as figure 1 with figure 2 As shown, the premixed fuel nozzle includes an outer tube 1, a suspension flange 2, an inner tube 14, an air swirler 10, a cup sleeve 11, a fuel injection column 12, a fuel injection hole 13 and a bellows 15; the inner tube 14 and the outer tube A fuel gas channel is formed between the tubes 1 , an air channel is inside the inner tube 14 , and an air swirler is arranged outside the outer tube 1 and communicated with the fuel gas channel. The air passes through the air swirler 10 to generate a swirling flow, and the fuel gas enters the fuel gas channel from the suspension flange 2, and is sprayed out through the fuel injection hole 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com