A diversion structure of a combustor premixed fuel nozzle

A fuel nozzle and combustion chamber technology, applied in the combustion chamber, continuous combustion chamber, combustion method, etc., can solve the problems of uneven mixing of air and fuel, tempering/flame adhesion, affecting flame stability, etc. Air distribution, uniform axial velocity distribution, improved uniformity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

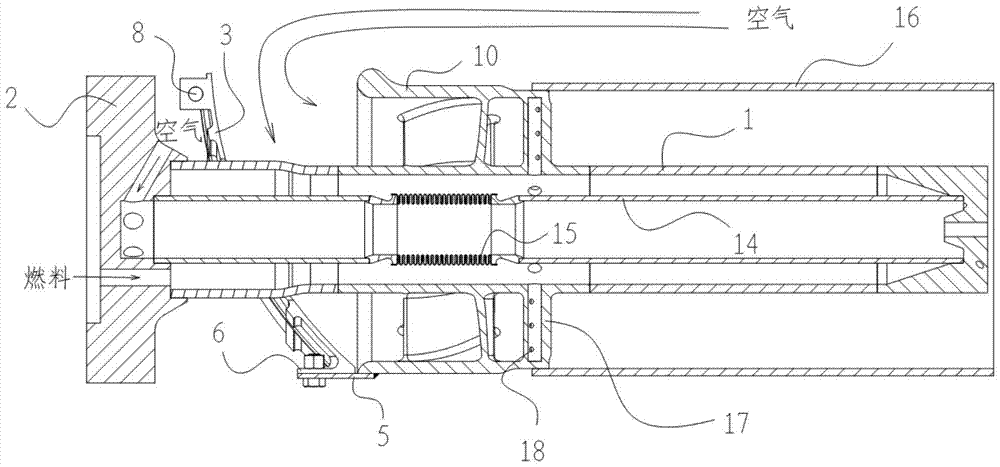

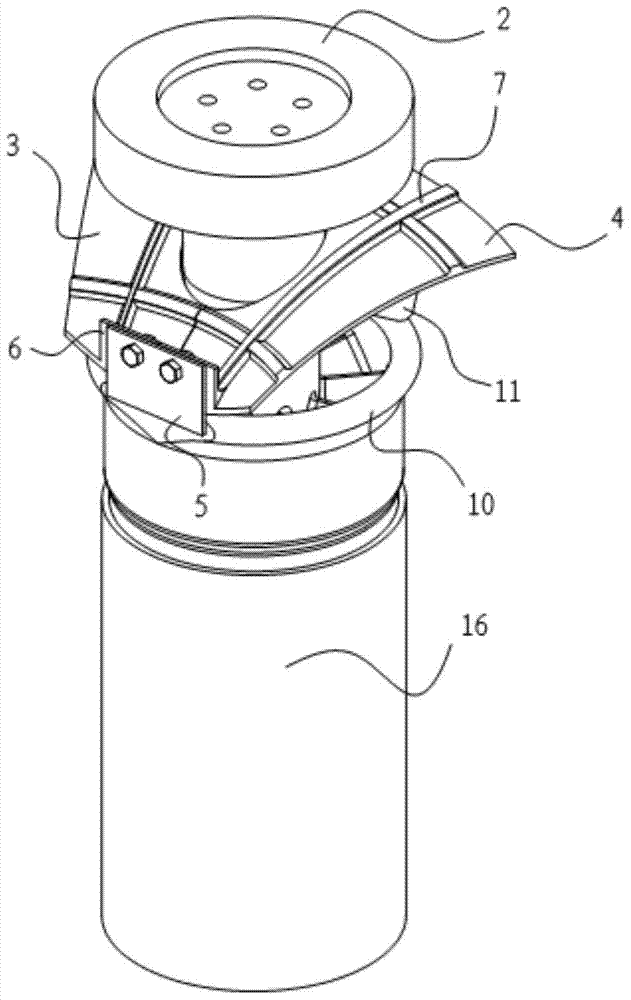

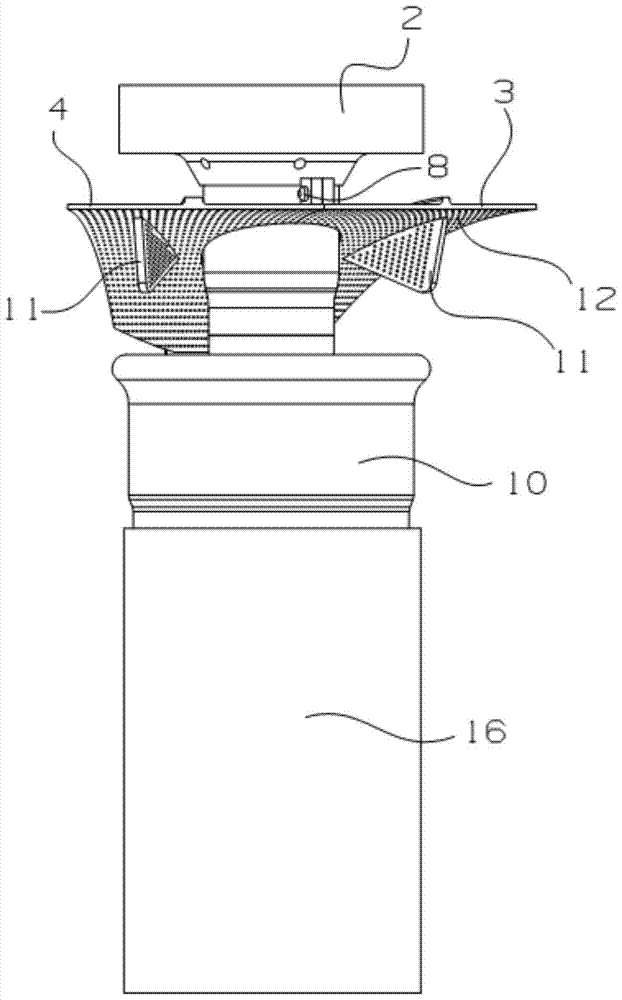

[0020] Such as Figure 1 ~ Figure 3 As shown, the combustion chamber premix fuel nozzle provided by the present invention includes an outer pipe 1, a suspension flange 2, an air swirler 10, an inner pipe 14, a bellows 15, a cup sleeve 16, a fuel injection column 17, and a fuel injection hole 18 And the drainage structure, a fuel gas passage is formed between the inner pipe 14 and the outer pipe 1, the inner pipe 14 is an air passage, and the air swirler is arranged on the outside of the outer pipe 1 and connected with the fuel gas passage; the drainage structure is arranged on Between the suspension flange 2 and the air swirler 10, the air flow structure includes a first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com