Sonic ash remover capable of realizing airflow cutting based on cam movement

A soot remover and cam technology, which is applied in the fields of solid residue removal, combustion methods, lighting and heating equipment, etc., can solve the friction between the modulation disc and the generator chamber wall, the threat to the safety and stability of the soot blower, and the failure of the motor Start-up and other problems, to achieve the effect of low operation and maintenance costs, simple structure, and controllable working frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below based on the drawings.

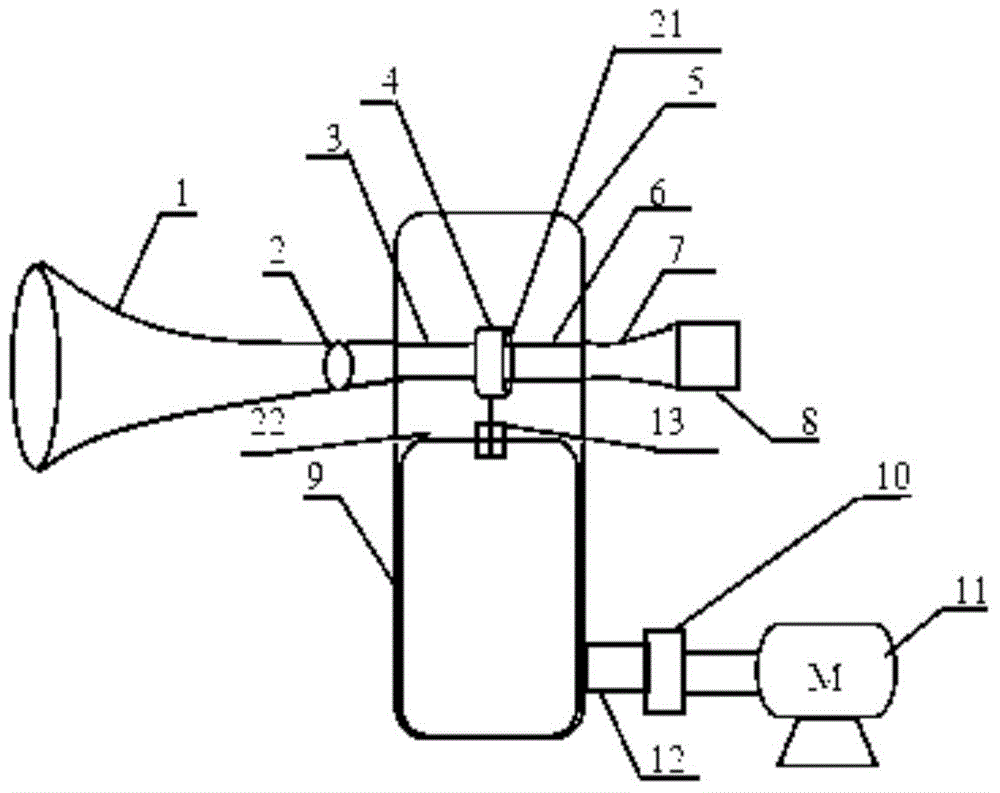

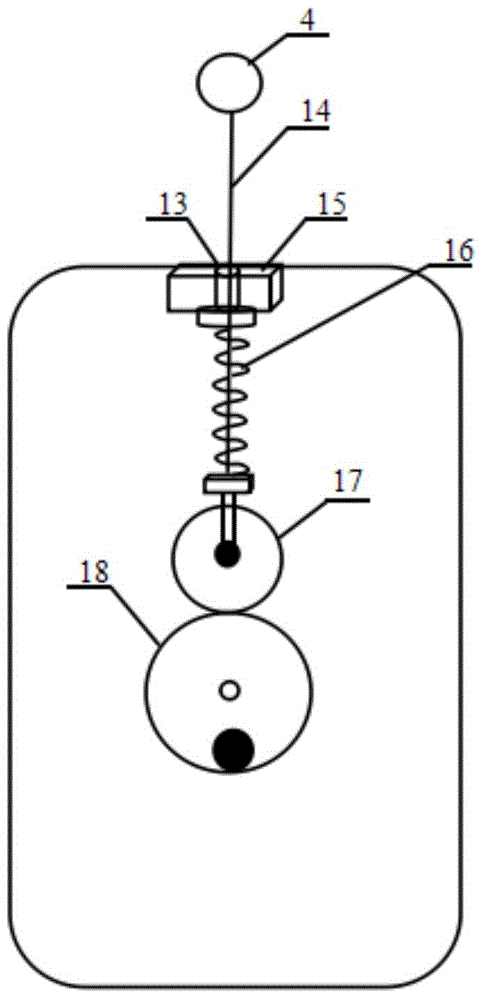

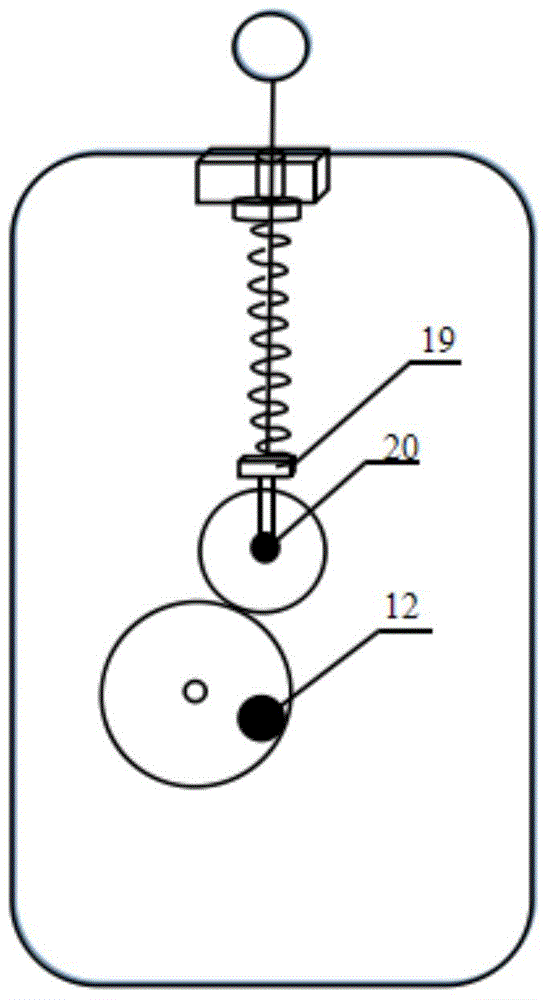

[0030] A sonic ash remover based on cam motion to achieve airflow cutting, including a mechanical box 9 and an air chamber 5, the air chamber 5 is the sounding device of the ash remover, and the air outlet 3 outside the air chamber 5 is connected to the sound reinforcement 1 side of the air inlet 6 is connected with high-pressure gas from an air compressor, and the air inlet 6 and the air outlet 3 are connected by a gas channel 21, and a cam 18 is installed in the mechanical box 9, so The cam 18 is driven by the driving device to rotate, and a guide wheel 17 is provided tangent to the outer circle of the cam 18, and the guide wheel 17 is connected to a connecting rod 14 through a spring 16 and the connecting rod 14 The other end is connected to the circular shielding piece 4, which reciprocates up and down under the action of the connecting rod 14. The high-pressure airflow in the gas channel 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com