Anti-deformation solid wood core floor

A solid wood core, anti-deformation technology, applied in the direction of wood layer products, wood processing appliances, floors, etc., to achieve the effect of stable structure, saving wood, and not easy to break the wood edge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

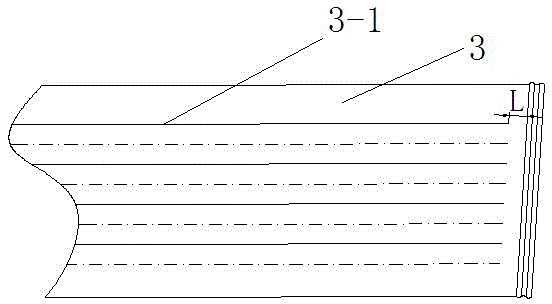

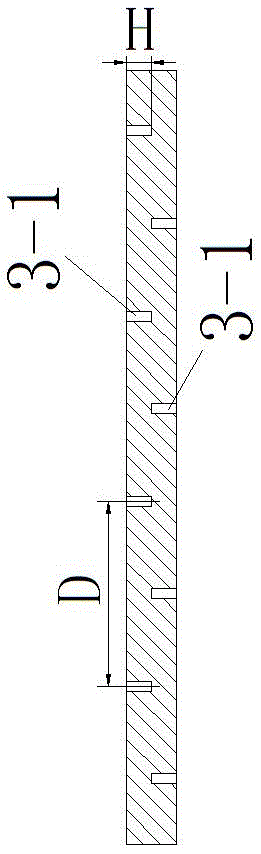

[0035] Embodiment 1: see attached figure 1 , attached figure 2 , attached image 3 , a kind of anti-deformation solid wood core floor, comprising the veneer layer 1 that is arranged on the bottom, the surface layer 2 that is arranged on the upper surface, the solid wood core material layer 3 that is positioned between the surface layer 2 and the veneer layer 1, between the surface layer 2 and the solid wood A balance layer 4 is provided between the core material layers 3 and between the veneer layer 1 and the solid wood core material layer 3, and a plurality of longitudinal anti-deformation sawing lines are uniformly distributed along the transverse direction on the upper surface and the lower surface of the solid wood core material layer 3 respectively. Groove 3-1, the vertical anti-deformation sawing groove 3-1 of this embodiment is perpendicular to the surface of the solid wood core material layer 3, and the multiple longitudinal anti-deformation sawing grooves 3-1 on the...

Embodiment 2

[0043] Embodiment 2: see attached Figure 4 , attached Figure 5 , an anti-deformation solid wood core floor, a plurality of longitudinal anti-deformation sawing grooves 3-1 and transverse deformation-resistant sawing grooves 3-2 are formed on the upper and lower surfaces of the solid wood core material layer 3 toward the thickness direction of the core material, And the longitudinal and transverse anti-deformation sawing grooves 3-1 and 3-2 on the upper and lower surfaces are staggered from each other. In this embodiment, the longitudinal anti-deformation sawing groove 3-1 and the transverse deformation-resistant sawing groove 3-2 are oblique grooves.

[0044] Follow these steps when manufacturing warp-resistant solid wood core floors:

[0045] 1. Take the length of the wood grain of the finger-jointed integrated core board as the length of the solid wood core floor, and the width of the wood grain of the solid wood core layer 3 core board as the width of the solid wood cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com