Polycrystalline quartz ceramic crucible and preparation method thereof

A technology of quartz ceramics and crucibles, which is applied in the field of polycrystalline quartz ceramics crucibles and its preparation, can solve problems such as reduced photoelectric conversion efficiency, poor quality of corners of silicon ingots, cracking of silicon ingots or crucibles, etc., so as to improve photoelectric conversion efficiency and reduce The width of the red zone and the effect of reducing the proportion of black borders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The invention provides a kind of preparation method of polycrystalline quartz ceramic crucible, comprises the following steps:

[0052] coating the inner wall of the bare polycrystalline quartz ceramic crucible with a coating solution comprising quartz sand with a particle size of 10 μm to 150 μm, and drying to obtain a polycrystalline quartz ceramic crucible;

[0053] The inner wall of the polycrystalline quartz ceramic crucible is provided with a coating;

[0054] The coating includes quartz sand with a particle size of 10 μm-150 μm.

[0055] In the present invention, the preparation method of the coating liquid preferably includes the following steps:

[0056] mixing the slurry comprising the first quartz sand and the second quartz sand to obtain a coating solution;

[0057] The particle size of the first quartz sand is 10 μm to 80 μm;

[0058] The particle diameter of the second quartz sand is 70 μm˜150 μm.

[0059] In the present invention, the slurry including...

Embodiment 1

[0081] Put 3 parts of quartz sand particles with a particle size greater than 150 μm and a purity of not less than 99.99% into a ball mill, then add 2 parts of high-purity water (conductivity less than 2 s / cm), mix and ball mill for 8 hours to obtain a particle size of 10 μm to 80 μm Quartz sand slurry, the slurry viscosity is 100mPa.s;

[0082] Mix 1 part of ball-milled slurry, 1 / 5 part of silica sol, and 1 part of quartz sand with a particle size of 70 μm to 150 μm and stir for 1 hour to make them evenly mixed. Place the bare quartz ceramic crucible on the heater for heating. When the bare quartz ceramic crucible is heated to 60°C, apply brushing evenly on the inner wall of the bare quartz ceramic crucible. The coating thickness is 1900 μm, and then It was allowed to dry naturally for 3 hours to obtain a polycrystalline quartz ceramic crucible.

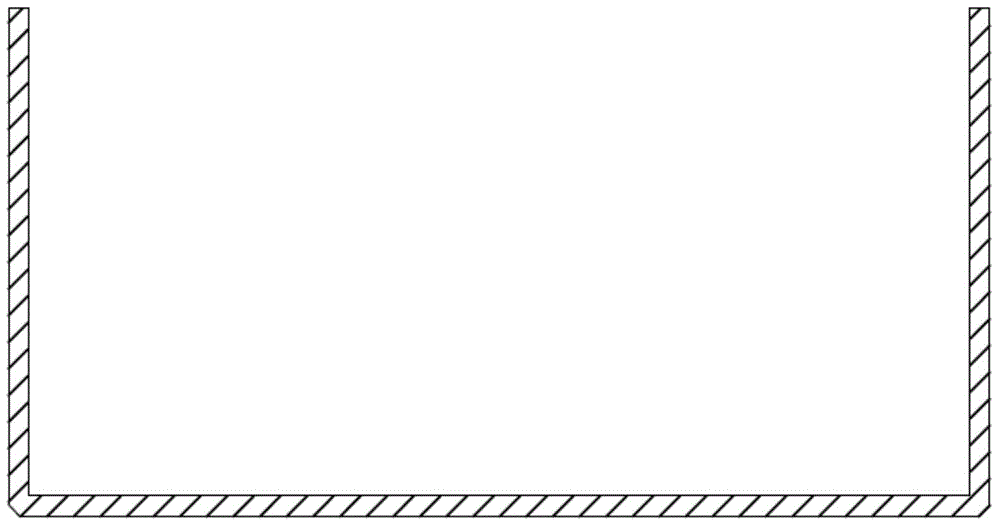

[0083] The embodiment of the present invention adopts traditional quartz ceramic crucible, and its structural schematic diagram i...

Embodiment 2

[0087] Put 3 parts of quartz sand particles with a particle size greater than 150 μm and a purity of not less than 99.99% into a ball mill, then add 2 parts of high-purity water (conductivity less than 2 s / cm), mix and ball mill for 8 hours to obtain a particle size of 10 μm to 80 μm Slurry of quartz sand;

[0088] Mix 1 part of ball-milled slurry, 1 / 5 part of silica sol, and 1 part of quartz sand with a particle size of 70 μm to 150 μm and stir for 1 hour to make them evenly mixed. Place the bare quartz ceramic crucible on the heater for heating. When the bare quartz ceramic crucible is heated to 58°C, spray it evenly on the inner wall of the bare quartz ceramic crucible by spraying. The thickness of the sprayed coating is 1100 μm. It was naturally dried for 3 hours to obtain a polycrystalline quartz ceramic crucible.

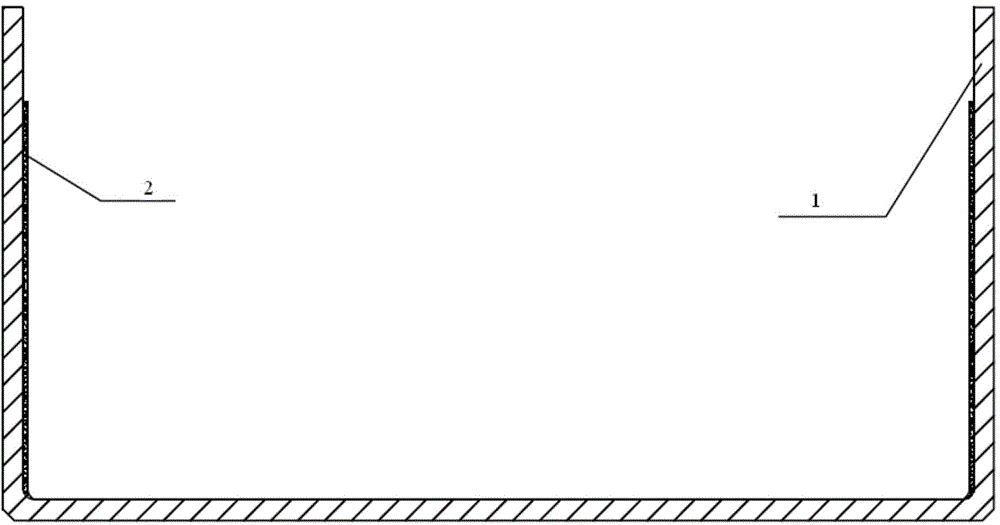

[0089] Figure 4 It is a schematic diagram of the structure of the traditional quartz ceramic crucible in Example 2 of the present invention after brushing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com